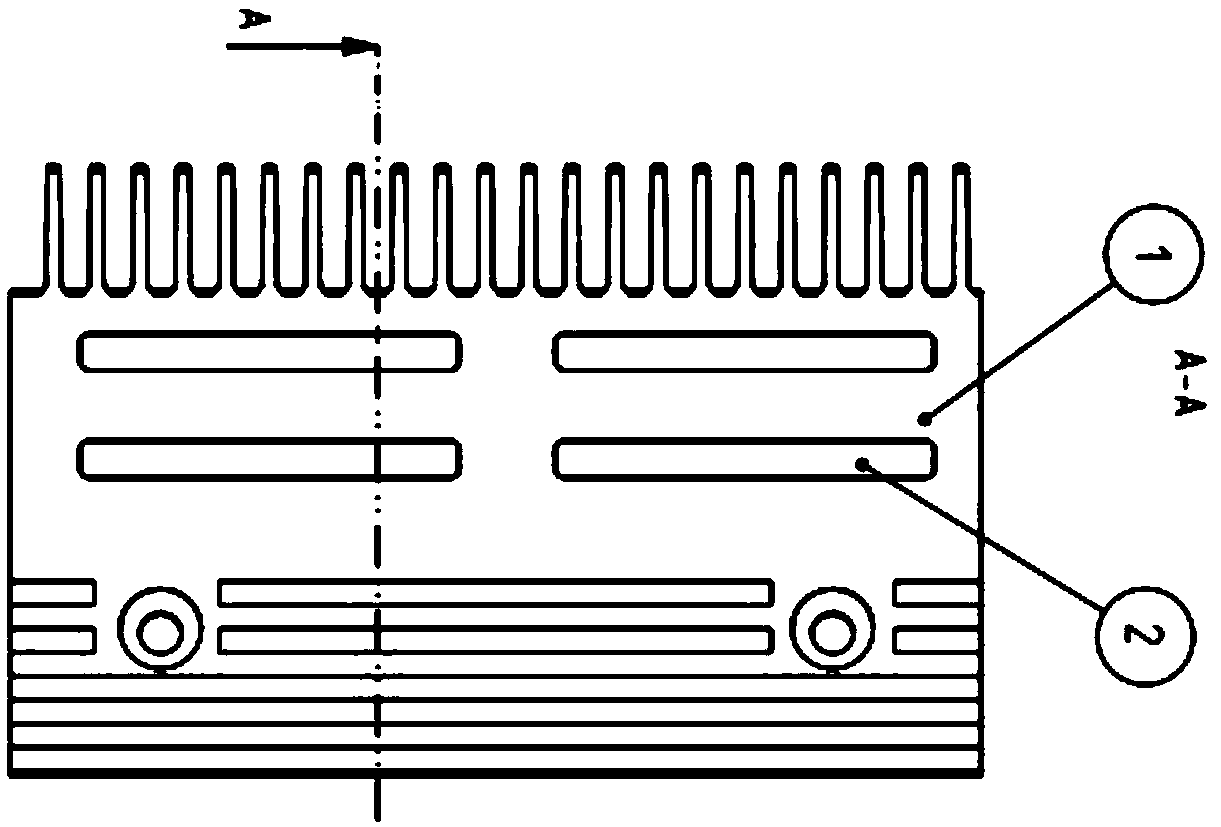

An elevator comb pedal

A technology of comb teeth and pedals, used in escalators, transportation and packaging, etc., can solve the problems of difficult to see the boundaries between comb teeth and step operation, insufficient light, etc., so as to avoid safety accidents and increase the degree of anti-skid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

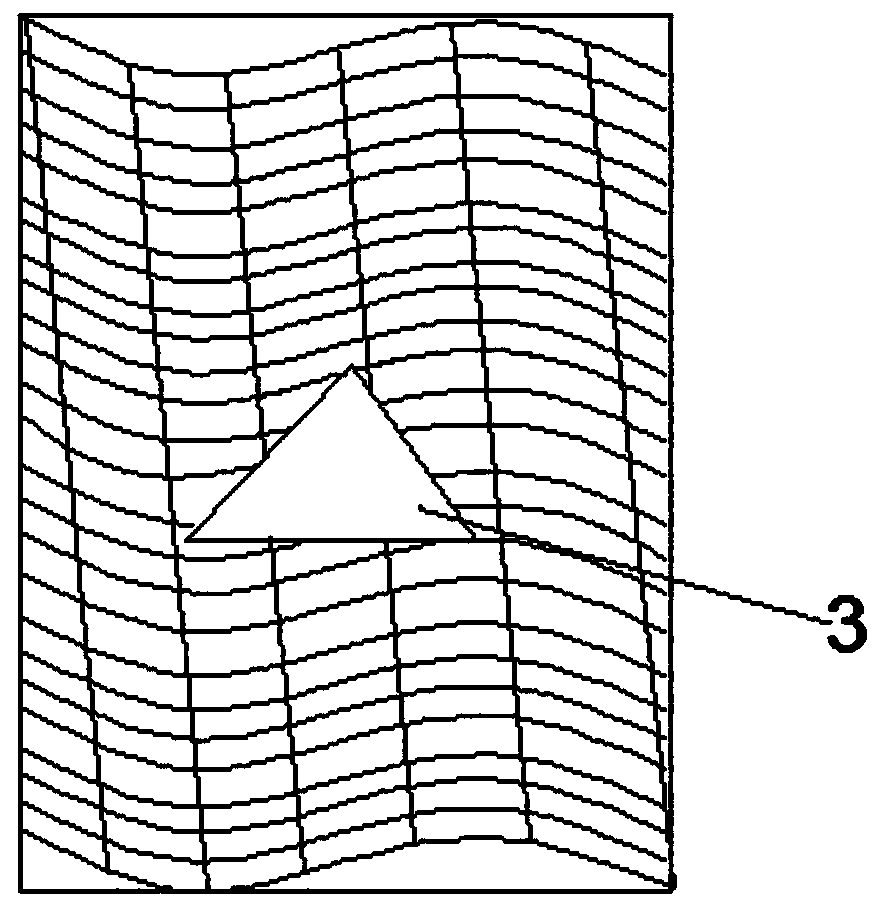

[0033] As an embodiment of the present invention, the movable clamping part includes a clamping part body 6 and a clamping positioning part, the clamping part body 6 is fixedly connected with the clamping positioning part, and the clamping positioning part is fixedly installed On the inner side of the clamping part body 6, the clamping positioning part passes through the clamping hole 5 to realize fixing, and the fixed height of the clamping part body 6 is consistent with the installation height of the comb teeth. In the present invention, for example, the clamping seat 4 is selected as a triangular base. At this time, when the clamping part body 6 matches the clamping seat 4, a clamping locator is installed inside the clamping part body 6. In this case In the embodiment, the clamping positioning part can be selected as a screw combination. At this time, the clamping hole 5 can be set as a threaded threaded hole. The screw combination passes through the threaded hole, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com