Glove having heat resistant silicone molded palm piece with protrusions extending therefrom

a silicone molded, glove technology, applied in the field of glove having a glove, can solve the problems of reducing the wear capacity of the glove, relatively high manufacturing cost of the glove, etc., and achieve the effect of reducing bulk, facilitating glove cleaning, and facilitating greater ease of manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

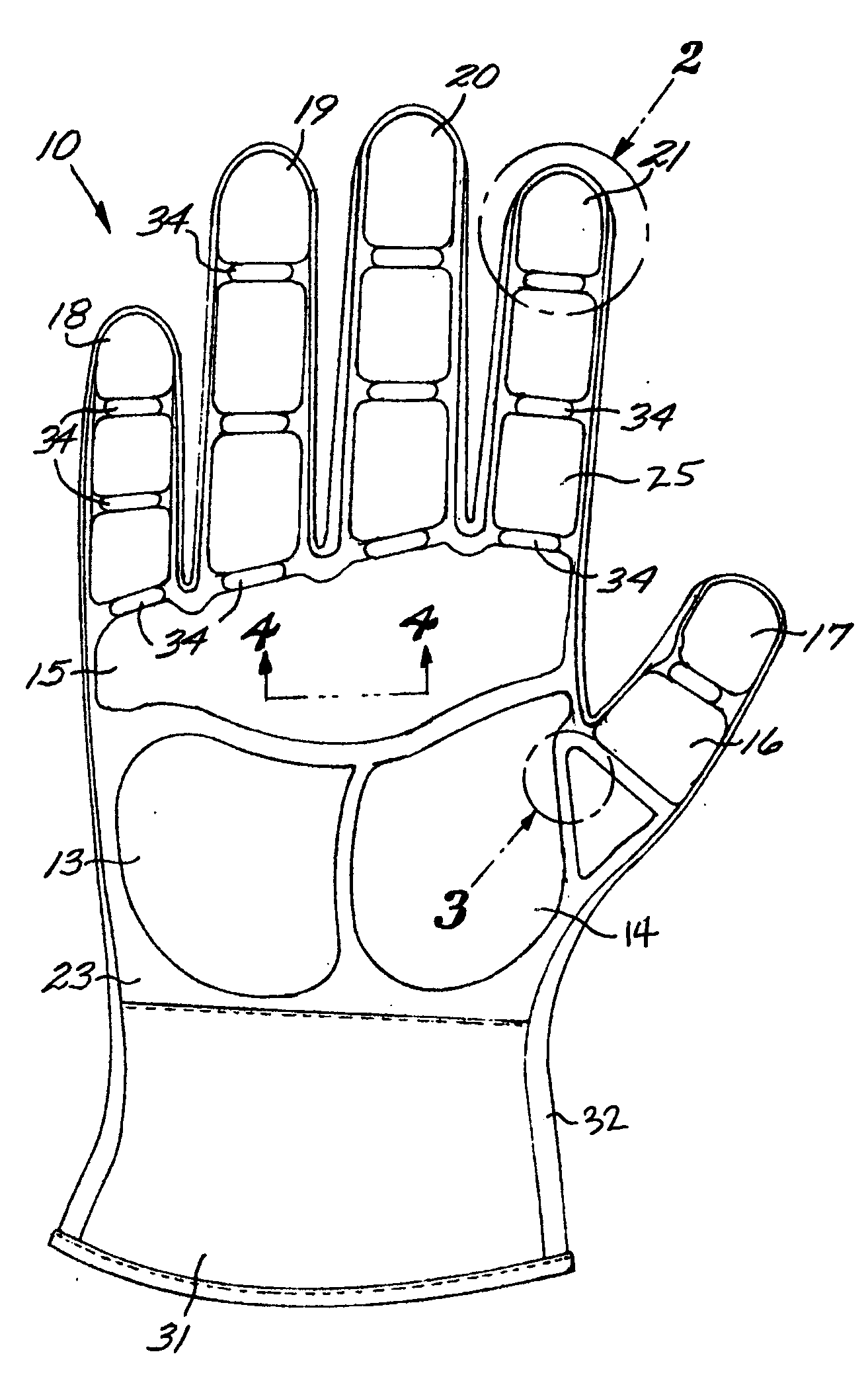

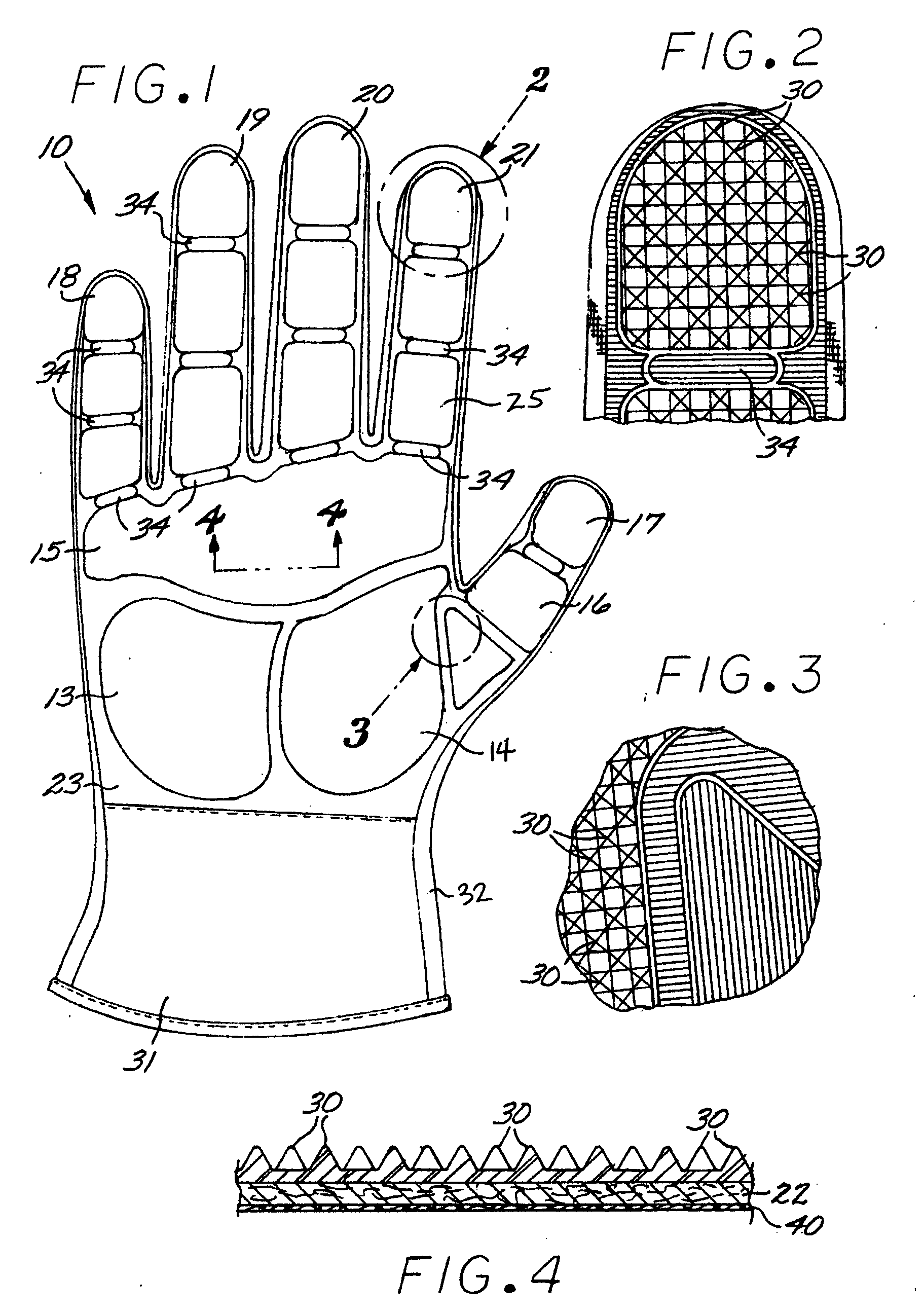

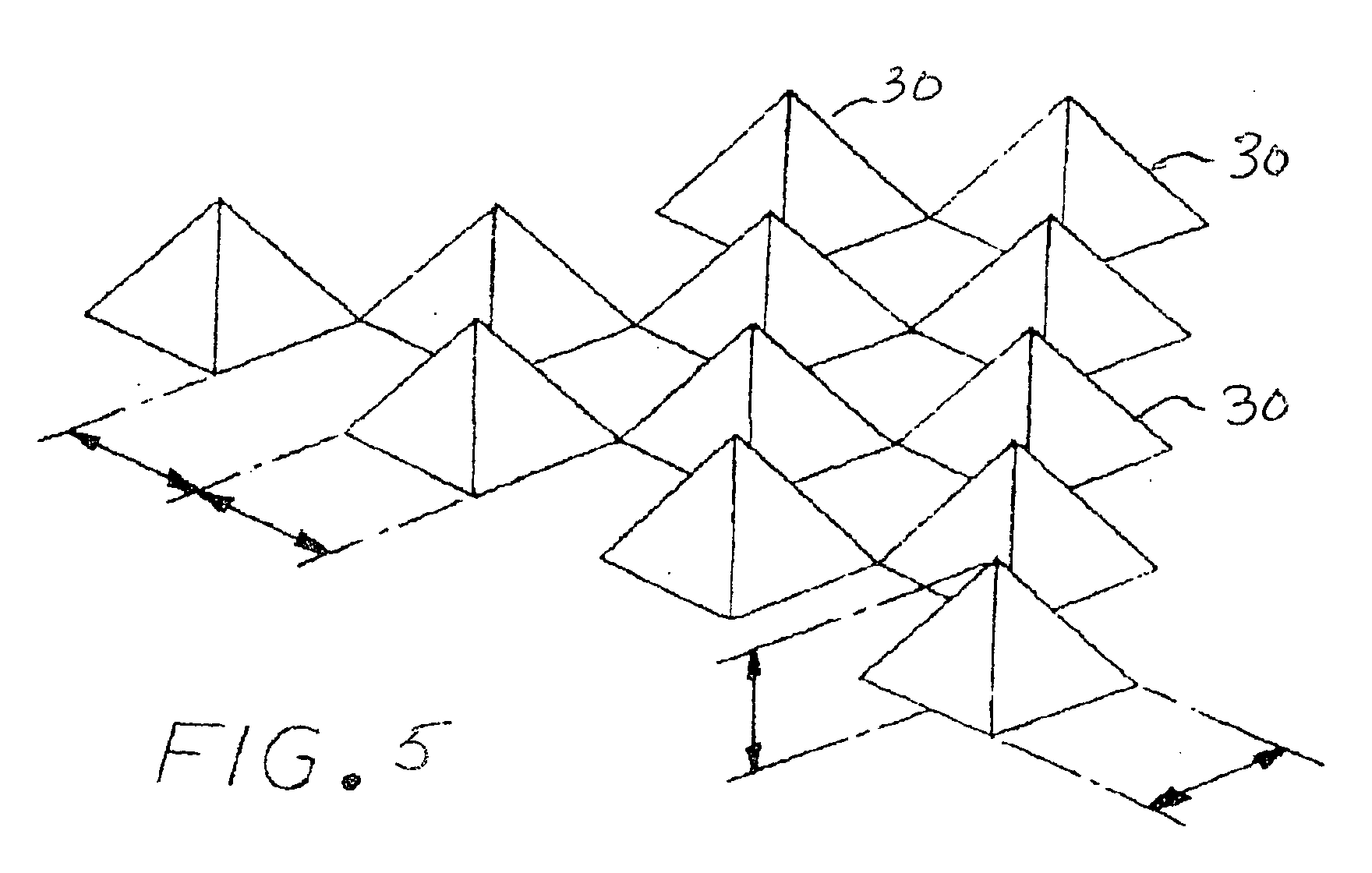

[0024]FIG. 1 is a simplified front view of glove 10 of the present invention illustrating in detail the palm portion 10 of the glove of the present invention. In particular, palm portion 10 comprises palm piece 12 (although only the right hand glove of a glove pair is illustrated, the construction of the left hand glove is identical), palm piece 12 comprising an integral, single silicone molded rubber member having a plurality of defined pattern portions 13, 14, 15 . . . 23 and 25. Palm portion 10 includes cuff 31 preferably made of synthetic rubber treated with heat resistant silicone. Reference number 32 refers to synthetic leather which is considered part of the glove back piece and thus will not be described herein. As will be set forth in more detail hereinafter, using silicone rubber for the palm piece material provides a glove that is heat resistant, a key feature of the present invention. In accordance with the teachings of the present invention, a plurality of protrusions 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com