Method of treating food waste using acidogenic koji mold

a technology of acidogenic koji and food waste, which is applied in the field of treating food waste using acidogenic koji mold, can solve the problems of unattractive pig raising using garbage, method largely out of use today, and fat in the pork to turn translucent or yellowish ting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0052]3.5 kg of seed koji of acidogenic koji mold (Asp. awamori) were added to 350 kg of kitchen scraps and leftovers discarded by 20 restaurants, adjusting the number of spores to 5×109 per gram, and aeration was begun. The water content of the raw material was 80%.

[0053]After 24 hours, the garbage had mostly liquefied, and the pH had decreased to 3.9. The viscosity fell from 11,000 mPa·s prior to treatment to 3200 mPa·s after treatment (B-type viscometer by Tokyo Keiki).

[0054]Aerated cultivation was continued by adding 350 kg of garbage and 350 g of seed koji to this fermented liquid daily over a period of 4 days, during which time the pH was always 4 or less and no putrefaction was observed.

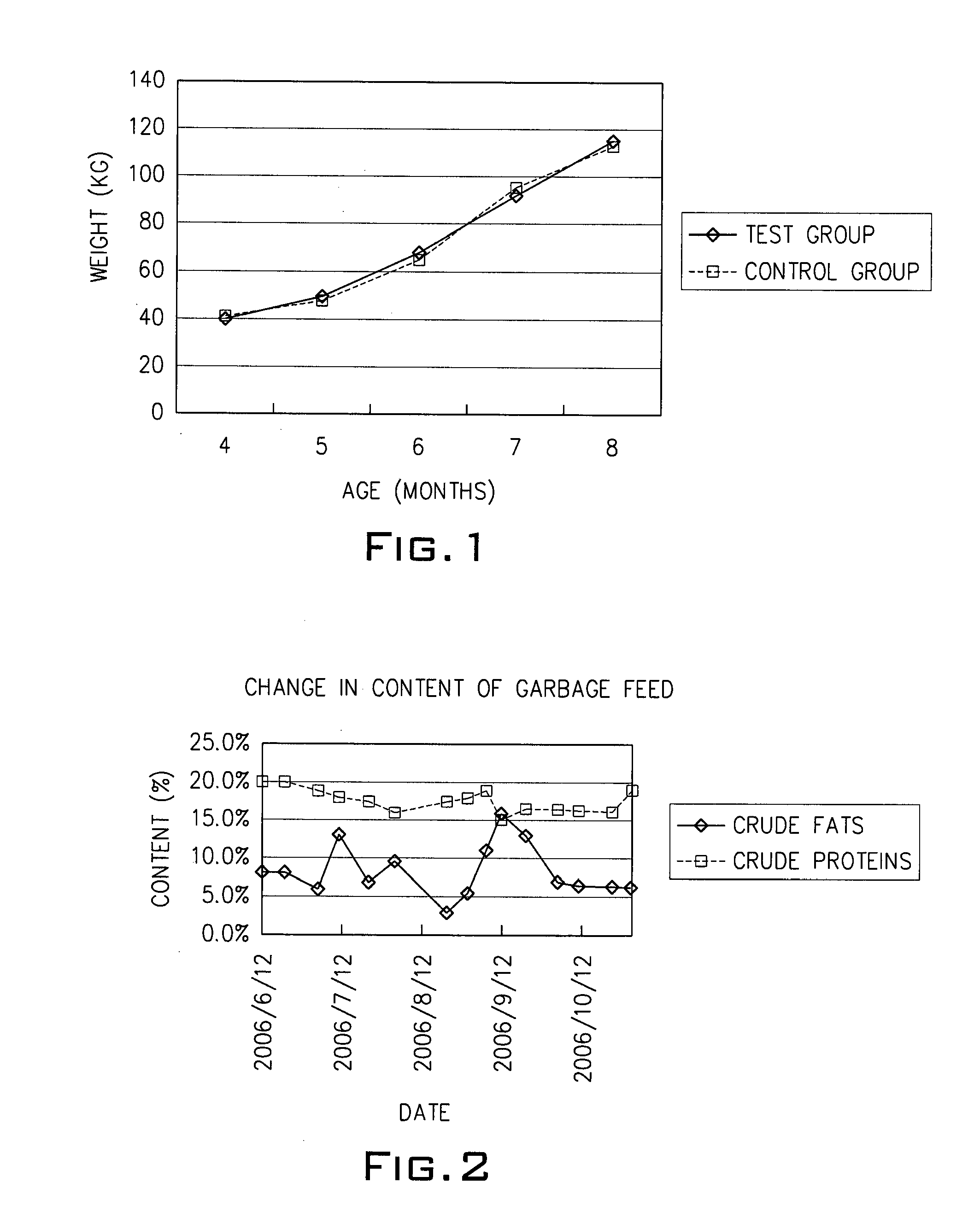

[0055]115 kg of maize was added to 1400 kg of this fermented liquid to adjust the water content to 75%, and the resulting feed was fed to 15 four-month old Berkshire pigs.

[0056]Additionally, as a control group, 15 four-month old Berkshire pigs were fed conventional blended feeds.

[0057]Thereaft...

example 2

[0064]The immune resistance improvement effect of the present feed composition was tested in mice.

[0065]Twelve mice were divided into two groups of six. The test group was given the fermented garbage feed composition of Example 1 without restriction, and the control group was given the mixed feed composition indicated below.

Casein11.0%Barley bran15.6%Wheat bran6.0%Wheat gluten8.4%Leucine0.2%Lysine0.2%Phenylalanine0.3%Corn starch26.2%Corn oil15.0%Cellulose powder1.5%Sucrose10.0%Mineral mixture3.5%Vitamin mixture2.0%

[0066]In the test, the twelve mice in the test group and the control group were fed the respective feed compositions for 3 days, given subcutaneous injections of the Sarcoma180 virus, then further raised for a period of 14 days, and subjected to analysis.

[0067]The results are shown below.

TABLE 1Cancer WeightLiver WeightSpleen WeightControl0.280 ± 0.0861.344 ± 0.0790.160 ± 0.053Test0.166 ± 0.0931.219 ± 0.1590.120 ± 0.023

[0068]As is clear from this table, the weight of cance...

example 3

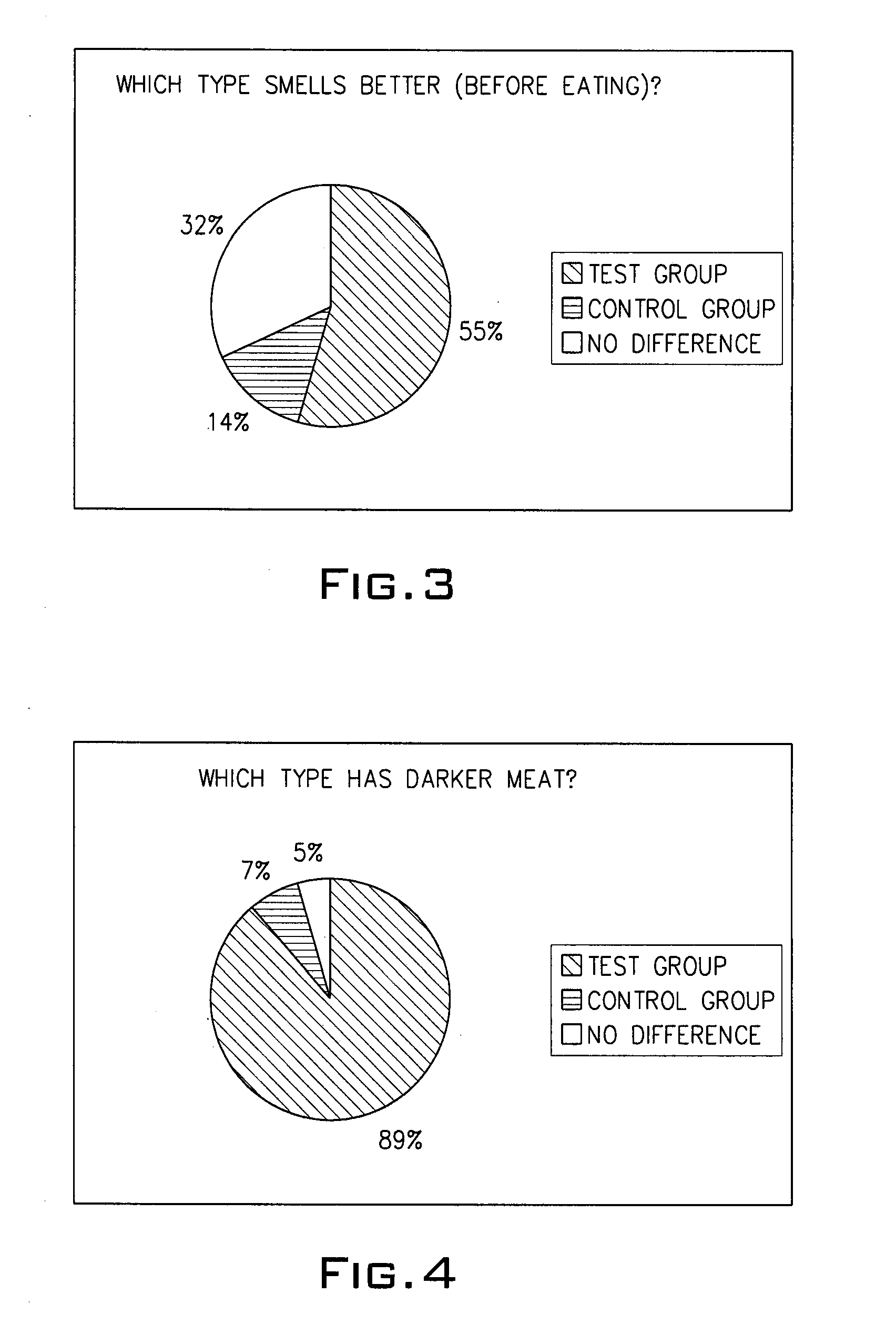

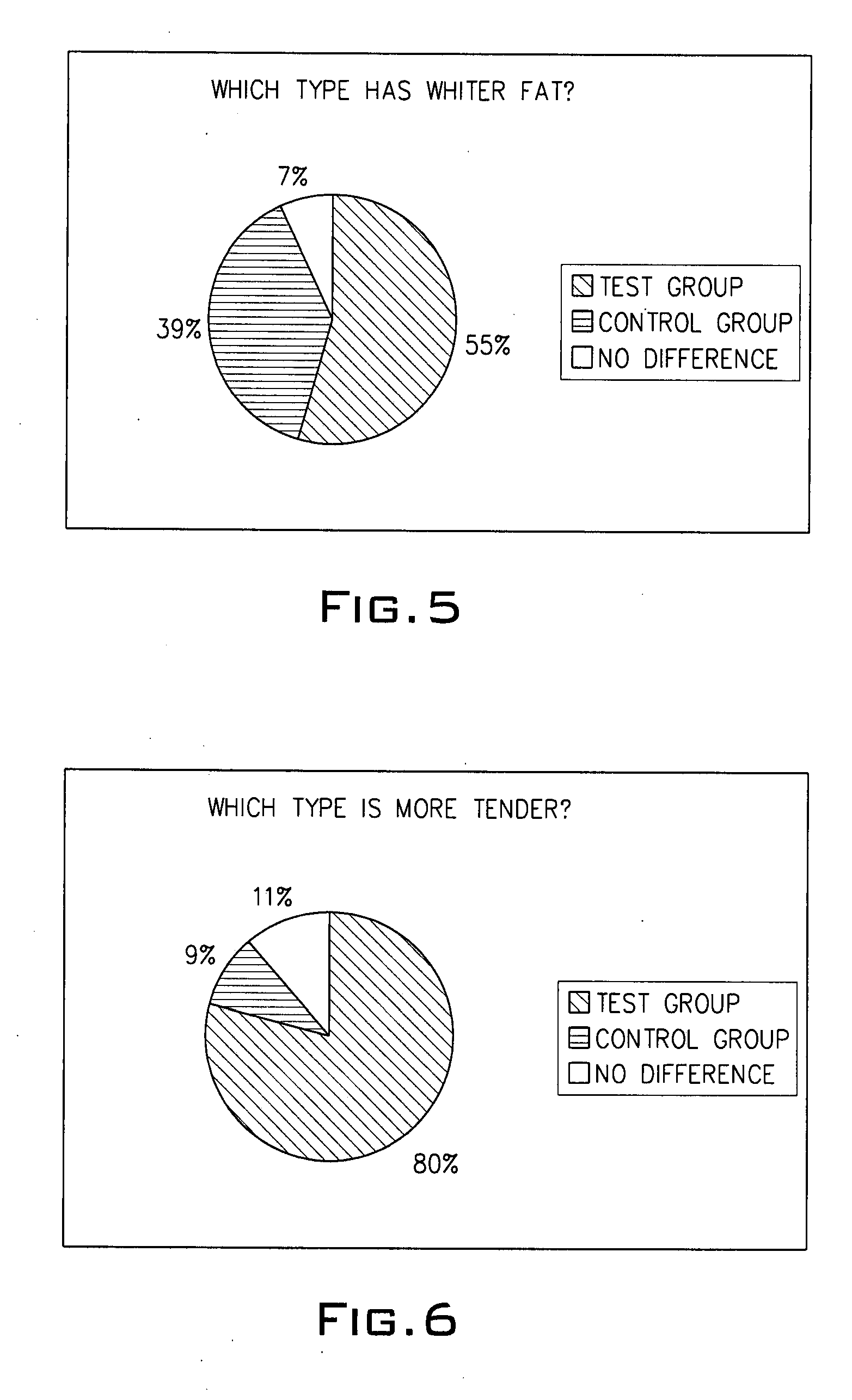

[0069]Next, the results of taste tests of pork from the pigs in the test of Example 1 shall be shown below.

[0070]Participants in Taste Test:[0071]20 male subjects[0072]24 female subjects

[0073]The results of judgments of the odor prior to eating, meat color, fat color, tenderness, taste, odor after eating and overall preference are shown respectively in FIGS. 3-9.

[0074]As is clear from the pie charts of FIGS. 3-9, the pork from pigs fed the fermented garbage feed composition received much higher evaluations than pork fed on conventional blended feeds.

[0075]While the major issue for previous pig farming techniques using garbage lay in how to achieve anything close to the quality of the pork from pigs fed blended feeds, the present feed production method is revolutionary in that it actually reverses the scales by producing pork of a quality greatly exceeding that of conventionally raised pigs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com