Method For Forming Dielectric Film And Method For Forming Capacitor In Semiconductor Device Using The Same

a technology of dielectric film and semiconductor device, which is applied in the direction of solid-state devices, coatings, chemical vapor deposition coatings, etc., can solve the problems of difficult to secure the dielectric capacity required for each unit cell, and deteriorating dielectric characteristic of the entire dielectric film, so as to improve the dielectric characteristic and leakage current characteristic of the capacitor used in the semiconductor devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0023

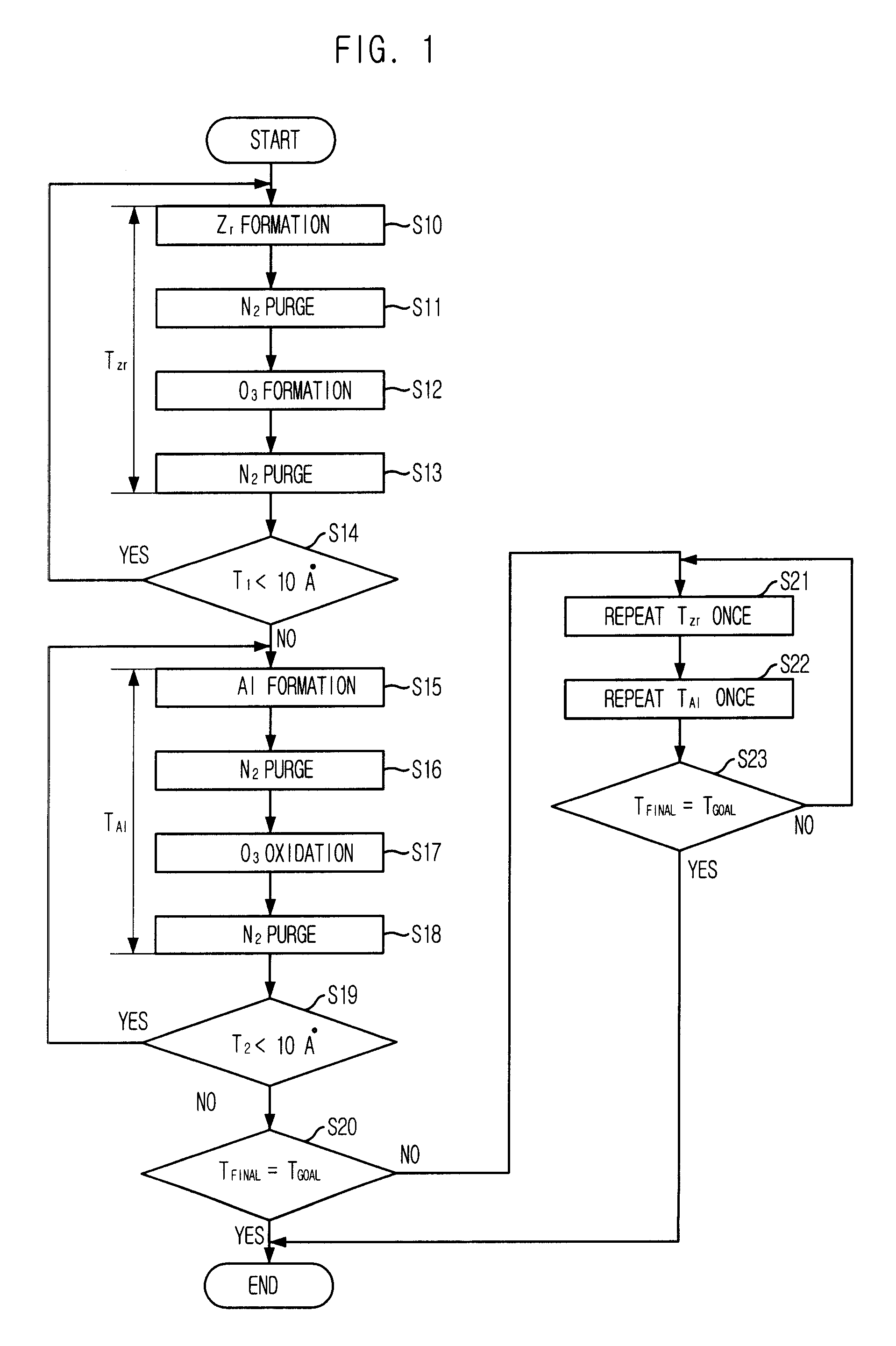

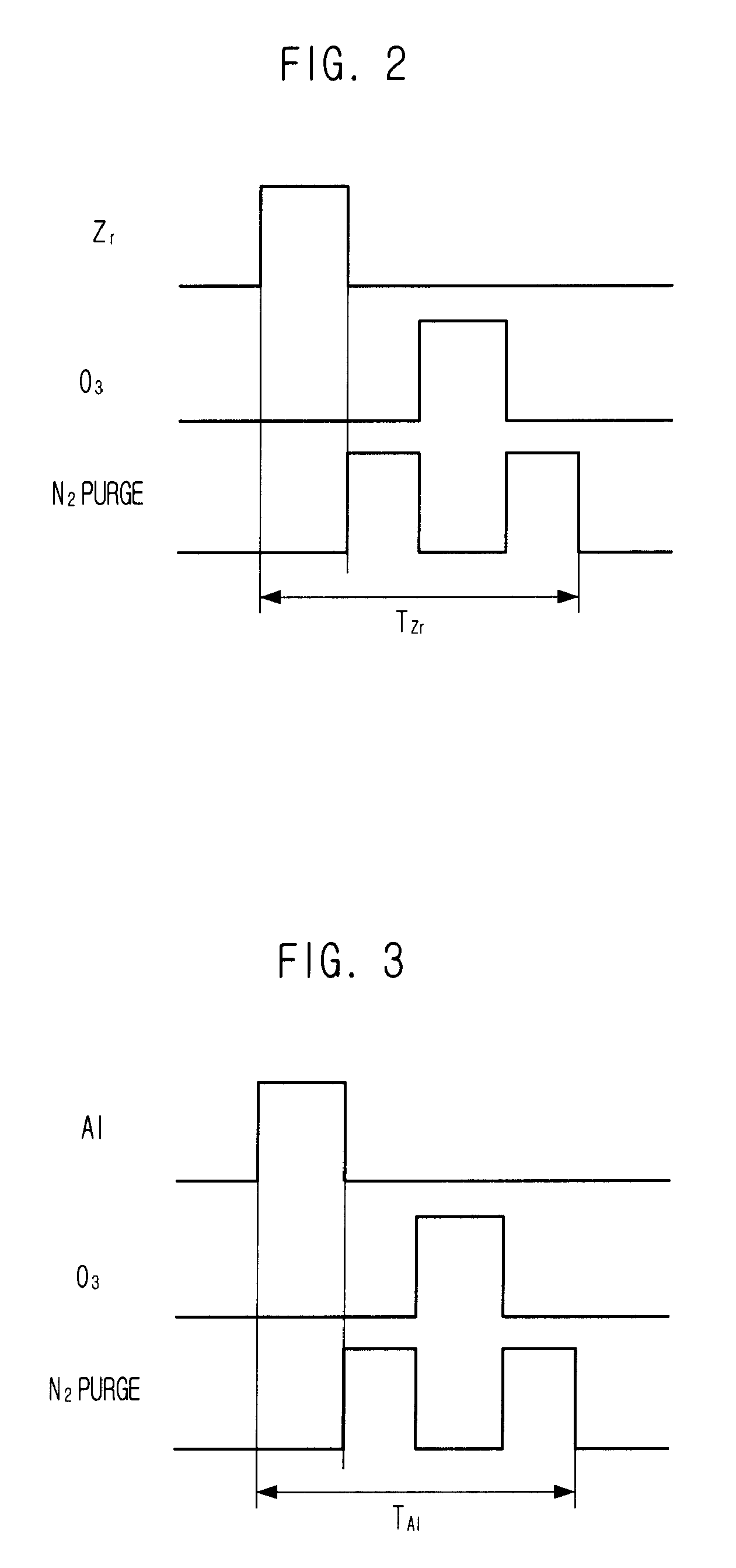

[0024]FIG. 1 is a process flowchart illustrated to describe a method for forming a dielectric film in a semiconductor device in accordance with a first embodiment of the present invention, FIG. 2 is a diagram illustrated to describe a sequential order of a zirconium dioxide (ZrO2) layer formation process, and FIG. 3 is a diagram illustrated to describe a sequential order of an aluminum oxide (Al2O3) layer formation process.

[0025]Referring to FIGS. 1 to 3, the method for forming a dielectric film in a semiconductor device in accordance with the first embodiment of the present invention includes forming a ZrO2 layer and then forming an Al2O3 layer, using an atomic layer deposition (ALD) method.

[0026]The formation process of the ZrO2 layer is as follows. One source gas selected from the group consisting of Zr(O-tBu)4, Zr[N(CH3)2]4, Zr[N(C2H5) (CH3)]4, Zr[N(C2H5)2]4, Zr(TMHD)4, Zr(OiC3H7)3(TMTD), and Zr(OtBu)4, is supplied inside a chamber of an ALD apparatus to adsorb zirconium (Z...

second embodiment

[0030

[0031]FIG. 5 is a flowchart illustrating a method for forming a dielectric film in accordance with a second embodiment of the present invention.

[0032]As shown in FIG. 5, the method for forming a dielectric film in accordance with the second embodiment of the present invention uses an ALD method like the first embodiment of the present invention. However, in the second embodiment, an Al2O3 layer is non-continuously formed over a wafer and then a ZrO2 layer is formed, instead of forming the ZrO2 layer first. Excluding such a difference, the second embodiment of the present invention is performed with substantially identical processes to the first embodiment of the present invention. Thus, detailed descriptions of the second embodiment are abridged herein for the convenience of description.

third embodiment

[0033

[0034]FIG. 6 is a flowchart illustrating a method for forming a dielectric film in accordance with a third embodiment of the present invention, and FIG. 7 is a diagram illustrating a formation process of simultaneously forming a [ZrO2]x[Al2O3]y layer.

[0035]Referring to FIGS. 6 and 7, the method for forming a dielectric film in a semiconductor device in accordance with the third embodiment of the present invention uses an ALD method to simultaneously form the [ZrO2]x[Al2O3]y layer.

[0036]A source gas such as ZrAl(MMP)2(OiPr)5, where Zr and Al are formed as one molecule, is supplied inside a chamber of an ALD apparatus to adsorb Zr and Al over a wafer, although it is not shown, at step S210. Herein, a temperature ranging from approximately 200° C. to approximately 350° C. is maintained inside the chamber. Subsequently, N2 gas is supplied inside the chamber to purge the remaining source gas, which did not become adsorbed, out of the chamber at step S211. Next, O3 is supplied inside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com