Ethanol modifier and its application

a technology of ethanol and modifiers, applied in the field of fuel modifiers, can solve the problems of increasing friction, poor lubrication properties, poor water solubility of ethanol fuel, etc., and achieve the effects of improving the combustion performance of ethanol, reducing the corrosion of ethanol fuel, and increasing the antioxidation capability and stability of ethanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

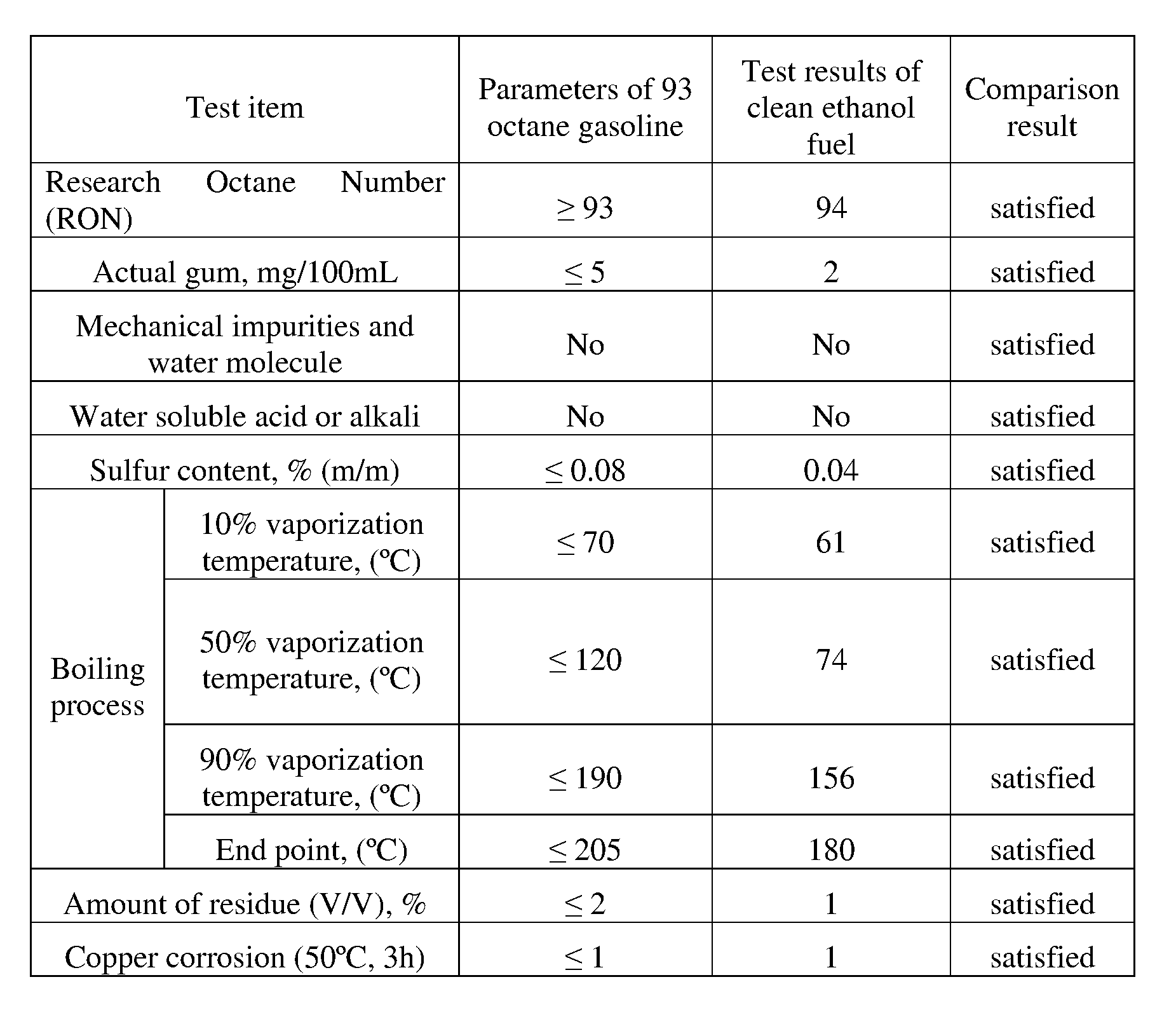

example 1

[0022] The various components forming the ethanol modifier are prepared according to the below weight percentages: butyl acetate 15%; alkylphenol polyoxyethylene TX-4 3%; 2,6-butylated hydroxytoluene 3%; benzotriazole 3%; phenyl-α-naphthylamine 3%; barium naphthanate 2%; tetrachloroethylene 14%; chlorinated paraffin 8%; methyl tert-butyl ether 26%; the mixture of isopropanol and isobutyl alcohol 23%, the ratio of isopropanol and isobutyl alcohol is 1:1 by volume.

[0023] In accordance with the present example, the ethanol modifier is prepared by the steps of: mixing the isopropanol and isobatyalcohol proportionally and then adding them into a mixing plant; adding solids, such as butylated hydroxytoluene and benzotriazole, and the thick components into the mixing plant; mixing in a speed of 200 revolutions per minute to dissolve and dilute the added components into an uniform liquid; adding the other modifier components into the mixing plant and mixing at a speed of 800 revolutions pe...

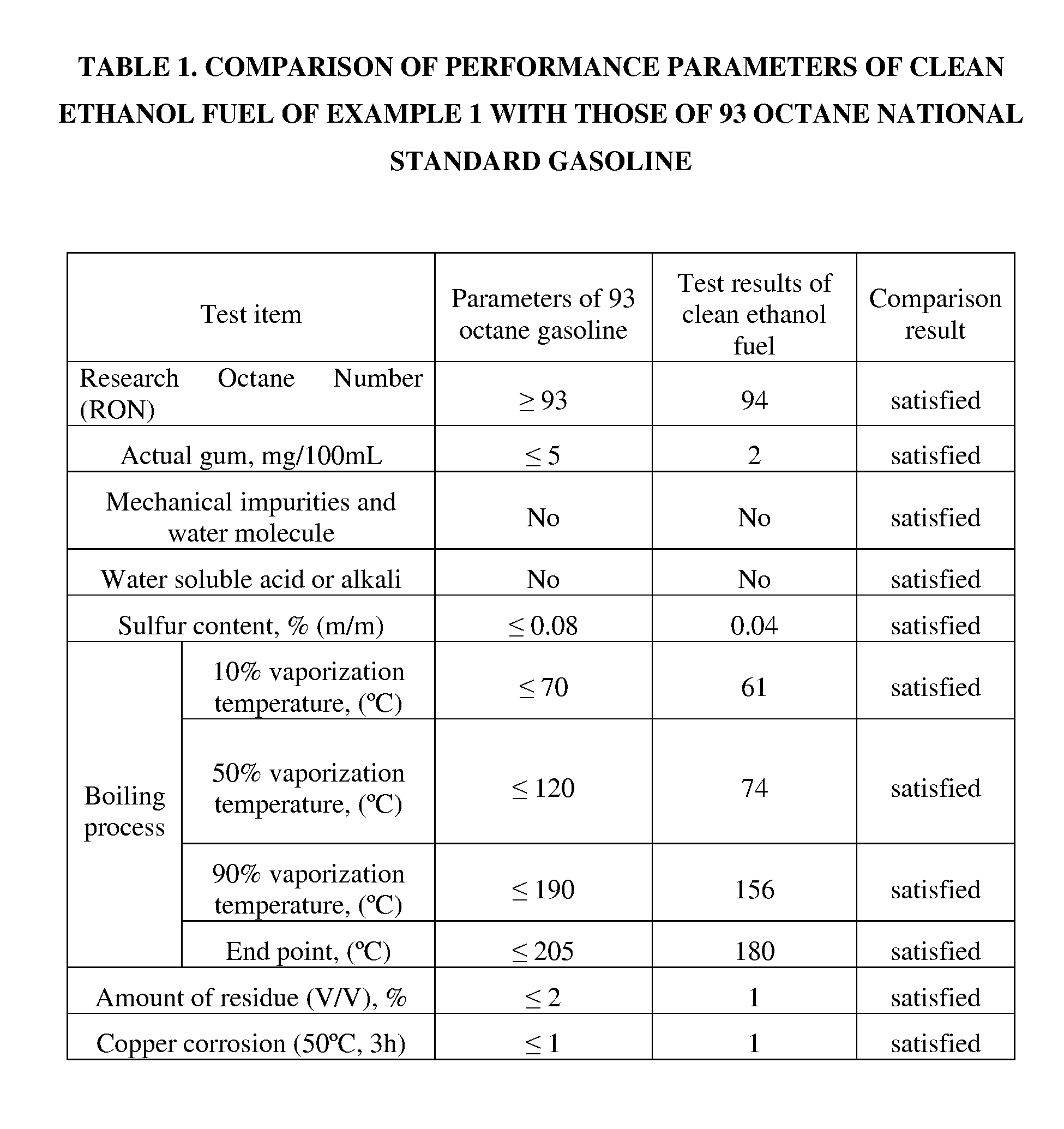

example 2

[0031] The various components forming the ethanol modifier are mixed according to the below weight percentages: ethyl acetate 6%; butyl acetate 8%; alkylphenol polyoxyethylene TX-7 2.5%; 2,6-butylated hydroxytoluene 2.5%; benzotriazole 3.5%; phenyl-α-naphthylamine 2%; phenyl-β-naphthylamine 2%; manganese naphthanate 2.5%; tetrachloroethylene 15%; chlorinated paraffin 7%; methyl tert-butyl ether 23%; the mixture of normal butanol and isooctanol 26%, the ratio of normal butanol and isooctanol being 7:3 by volume.

[0032] In accordance with the present example, the ethanol modifier is prepared by the steps of: mixing the normal butanol and isooctanol in given proportions and then adding them into a mixing plant; adding the solids, such as butylated hydroxytoluene and benzotriazole, and the thick components into the mixing plant; mixing at a speed of 200 revolutions per minute to dissolve and dilute the added components into an uniform liquid mixture; adding the remaining components into...

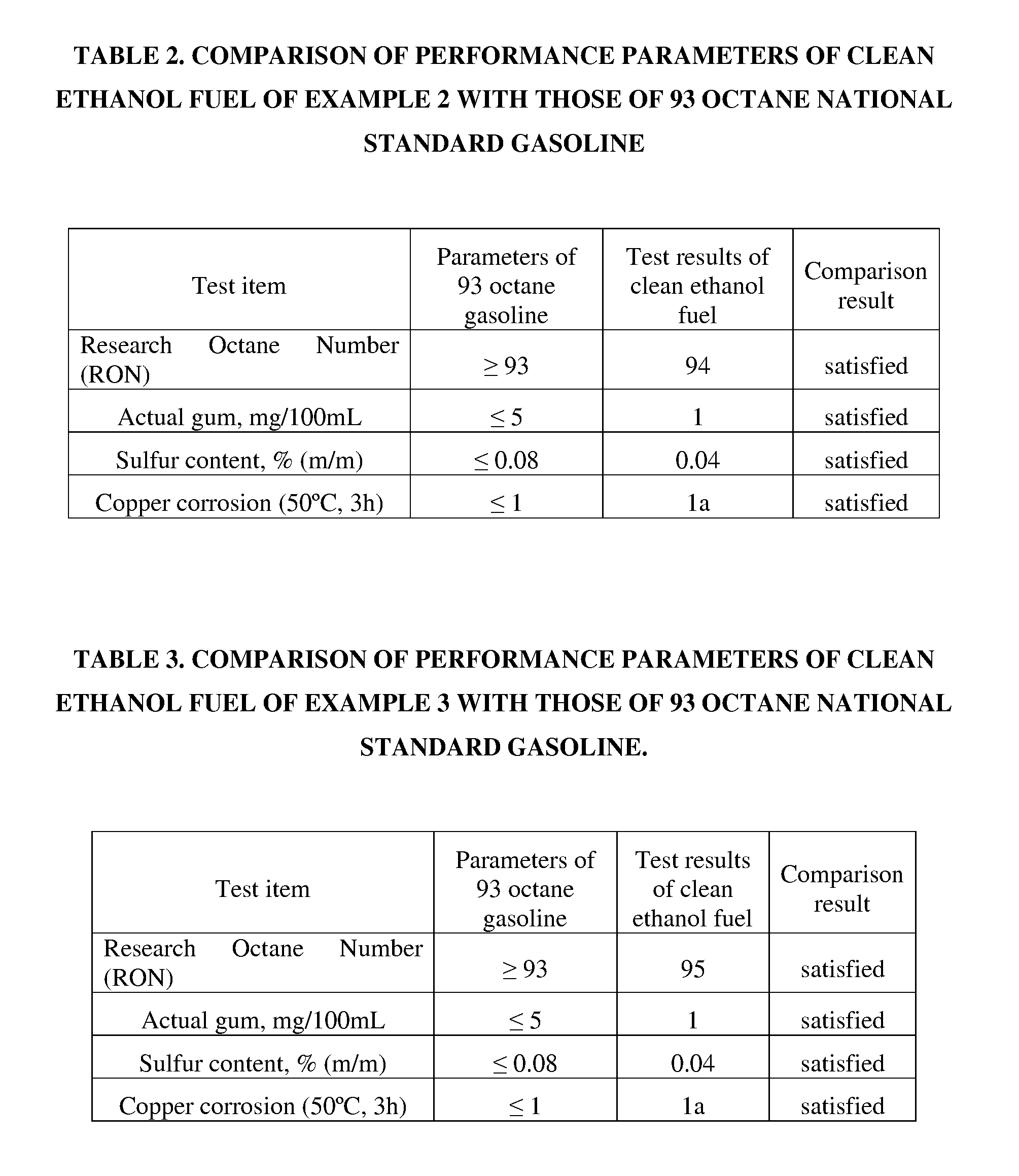

example 3

[0035] The various components forming the ethanol modifier are prepared according to the below weight percentages: butyl acetate 15%; tetrachloroethylene 14%; chlorinated paraffin 8%; butylated hydroxytoluene 4%; benzotriazole 4%; phenyl-α-naphthylamine 4%; methyl tert-butyl ether 26%; alkylphenol polyoxyethylene TX-10 3%; manganese naphthanate 2%; and the mixture of isopropanol and normal butanol 20%, the ratio of isopropanol and normal butanol being 1:1 by volume.

[0036] In accordance with the present example, the ethanol modifier is prepared by the steps of: mixing the normal butanol and isopropanol proportionally and then adding them into a mixing plant; adding the solids, such as butylated hydroxytoluene and benzotriazole, and the thick components into the mixing plant; mixing in a speed of 200 revolutions per minute to dissolve and dilute the added components into an uniform liquid mixture; adding the remaining components into the mixing plant and mixing at a speed of 800 revo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antioxidant | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com