Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

a fuel management system and engine technology, applied in the direction of machines/engines, output power, electric control, etc., can solve the problems of non-uniform ethanol injection and delay of ethanol injection, and achieve the effects of facilitating increased engine efficiency, gasoline savings, and improved efficiency under driving conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

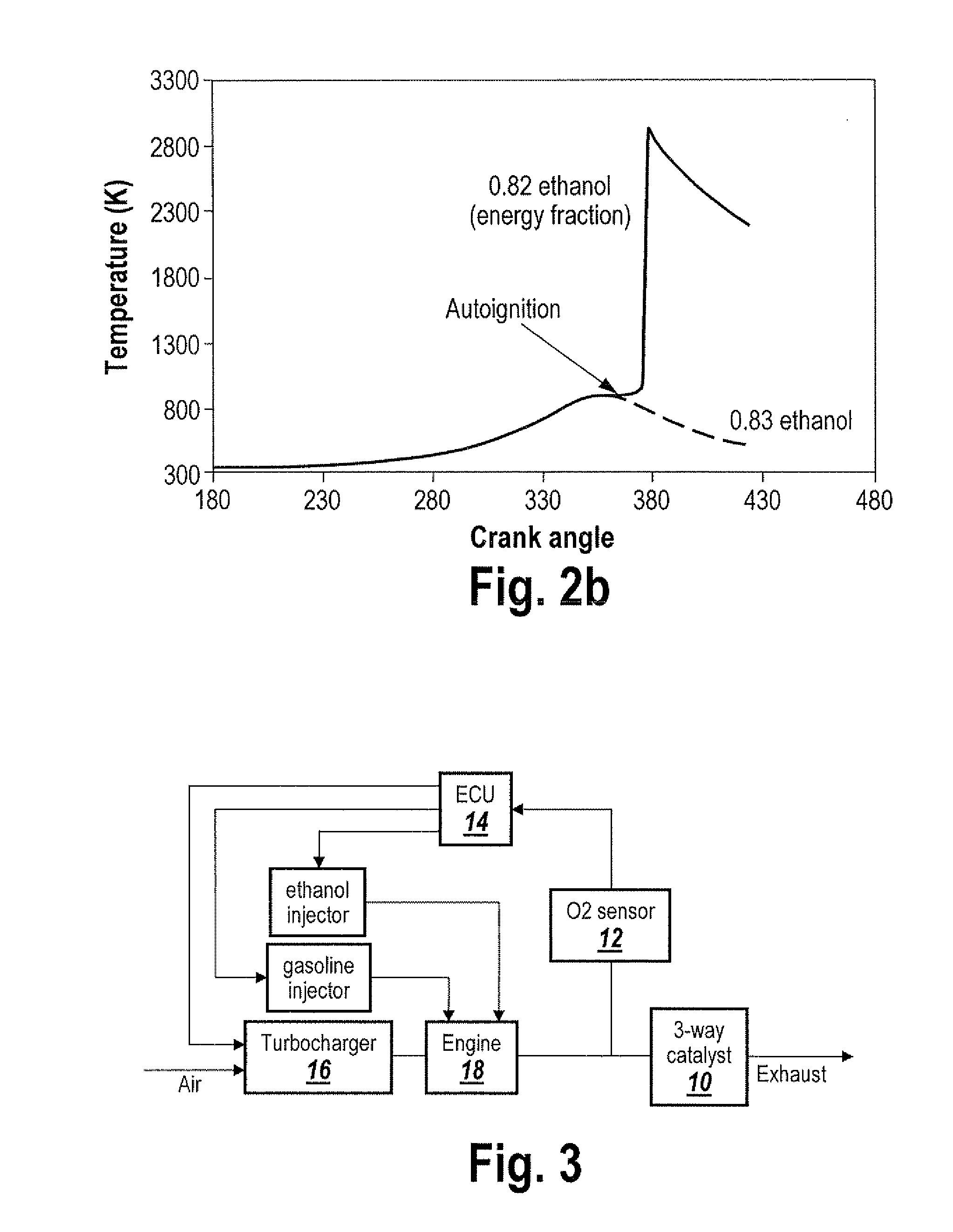

[0015] Ethanol has a heat of vaporization that is more than twice that of gasoline, a heat of combustion per kg which is about 60% of that of gasoline, and a heat of vaporization per unit of combustion energy that is close to four times that of gasoline. Thus the evaporative cooling of the cylinder air / fuel charge can be very large with appropriate direct injection of this antiknock agent. The computer model referenced below shows that evaporative cooling can have a very beneficial effect on knock suppression. It indicates that the beneficial effect can be maximized by injection of the ethanol after the inlet valve that admits the air and gasoline into the cylinder is closed. This late injection of the ethanol enables significantly higher pressure operation without knock and thus higher efficiency engine operation than would be the case with early injection. It is thus preferred to the conventional approach of early injection which is used because it provides good mixing. The model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com