High-quality non-quenched and tempered seamless steel tube for drilling and manufacturing method thereof

A technology of seamless steel pipe and manufacturing method, which is applied in the field of high-quality non-quenched and tempered seamless steel pipe for drilling and its manufacture, and can solve the problems of low reuse rate, low overall strength, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

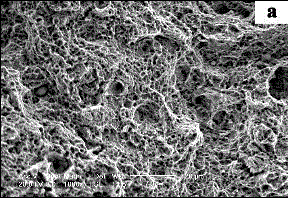

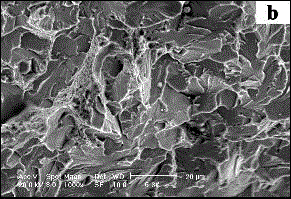

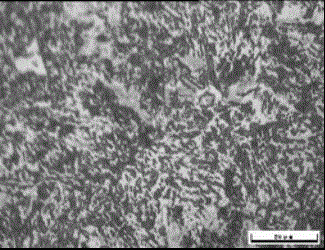

[0041] Example 1: The high-quality non-quenched and tempered seamless steel pipe for drilling in this example is composed of the following components by weight percentage: C: 0.36%, Si: 0.28%, Mn: 1.48%, Mo: 0.26%, V : 0.07%, Ti: 0.022%, Alt: 0.016%, P: 0.010%, S: 0.006%, N: 75ppm, H: 1.5ppm; O: 25ppm, As+Sn+Pb+Sb+Bi=0.038%, the rest is iron Fe and unavoidable The metallographic structure is uniform and fine granular bainite structure, the drilling pipe specification: 70.2×4.9×3300mm, its performance: tensile strength Rm: 1140MPa, yield strength Rp0.2: 970MPa, elongation A: 18% , Longitudinal impact energy A KU2 : 96J.

[0042] The manufacturing process of the present embodiment is as follows:

[0043] (1) Electric furnace smelting: Add molten iron and scrap steel to realize pre-removal of P and initial adjustment of composition to obtain primary molten steel, C: 0.56%, P: 0.060%, S: 0.070%;

[0044] (2) Refining in LF furnace: send molten steel from initial smelting to LF ...

Embodiment 2

[0052]Example 2: The high-quality non-quenched and tempered seamless steel pipe for drilling in this example is composed of the following components by weight percentage: C: 0.38%, Si: 0.25%, Mn: 1.66%, Mo: 0.27%, V : 0.08%, Ti: 0.030%, Alt: 0.018%, P: 0.006%, S: 0.004%, N: 55ppm, H: 1.2ppm; O: 15ppm, As+Sn+Pb+Sb+Bi=0.030%, the rest is iron Fe and unavoidable The metallographic structure is uniform and fine granular bainite structure, the specification of drilling pipe: 70.2×5.05×3050mm, its performance: tensile strength Rm: 1200MPa, yield strength Rp0.2: 1020MPa, elongation A: 16% , Longitudinal impact energy A KU2 : 81J.

[0053] The manufacturing process of the present embodiment is as follows:

[0054] (1) Electric furnace smelting: add molten iron and scrap steel to realize pre-removal of P and initial adjustment of components to obtain primary molten steel, C: 0.60%, P: 0.050%, S: 0.050%;

[0055] (2) Refining in LF furnace: send molten steel from initial smelting to ...

Embodiment 3

[0063] Example 3: The high-quality non-quenched and tempered seamless steel pipe for drilling in this example is composed of the following components by weight percentage: C: 0.37%, Si: 0.35%, Mn: 1.46%, Mo: 0.32%, V : 0.06%, Ti: 0.032%, Alt: 0.015%, P: 0.007%, S: 0.005%, N: 65ppm, H: 1.4ppm; O: 20ppm, As+Sn+Pb+Sb+Bi=0.033%, the rest is iron Fe and unavoidable The metallographic structure is uniform and fine granular bainite structure, the drilling pipe specification: 70.2×5.05×3250mm, its performance: tensile strength Rm: 1180MPa, yield strength Rp0.2: 1005MPa, elongation A: 16% , Longitudinal impact energy A KU2 : 84J.

[0064] The manufacturing process of the present embodiment is as follows:

[0065] (1) Electric furnace smelting: Add molten iron and scrap steel to realize pre-removal of P and initial adjustment of composition to obtain primary molten steel, C: 0.40%, P: 0.060%, S: 0.070%;

[0066] (2) Refining in LF furnace: send molten steel from initial smelting to L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com