Solar Cell Module and Photovoltaic Power Generator Using This

a solar cell module and solar cell technology, applied in the field of solar cell modules and photovoltaic power generators, can solve the problems of high production cost of substrates, difficult improvement of conversion efficiency, multicrystalline silicon solar cells, etc., and achieve the effect of reducing the ratio of outer peripheral regions, improving power generation efficiency (amount of power generation/area of solar cell modules), and improving design quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0285] Hereinafter, the results of experiments conducted on solar cell elements fabricated according to the foregoing embodiments will be shown.

[0286] As the substrate, a flat plate p-type multicrystalline silicon substrate of 150 mm×150 mm in size fabricated by a casing method having a specific resistivity of 2Ω·cm was used.

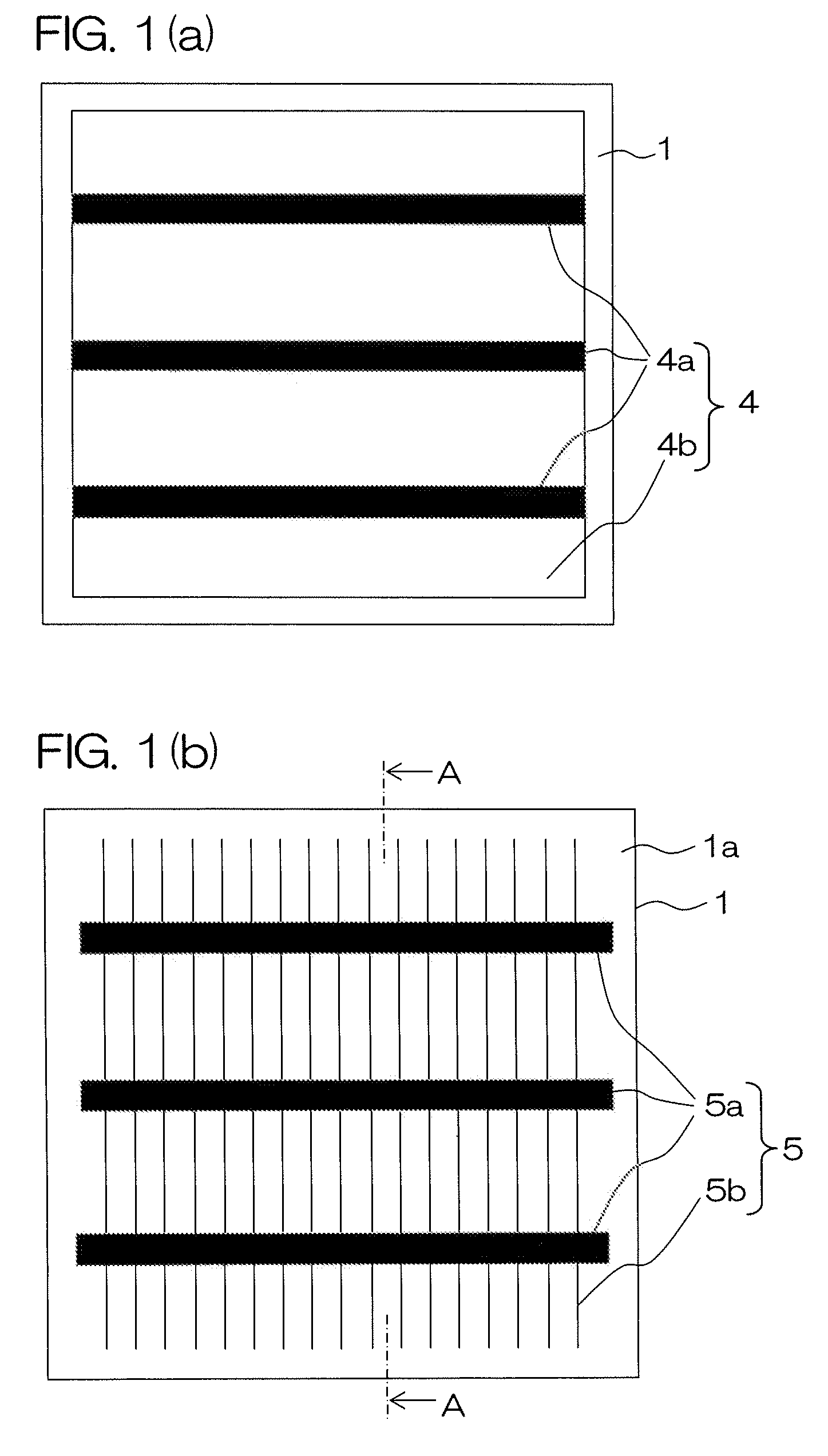

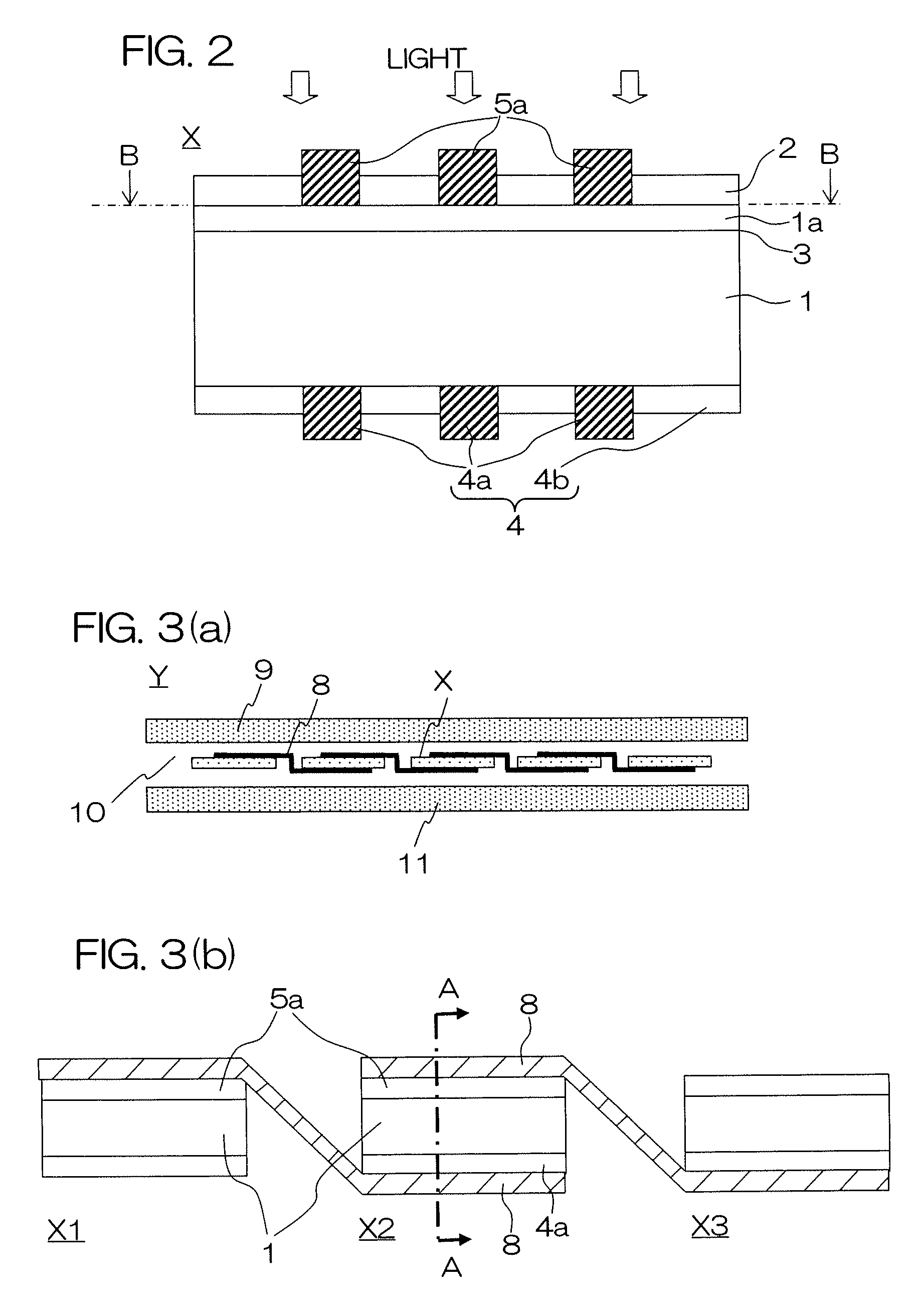

[0287] A paste including silver as a main component was printed and baked to form a surface electrode. The pattern for the surface electrode as a whole was formed by disposing three lines including one vertical line at the center of the substrate, and two lines axisymmetrically thereto. The bus bar electrodes 5a were made to have a length of 148.8 mm.

[0288] The widths of the bus bar electrodes 5a were varied to eight different values as 0.6, 0.8, 1.0, 1.2, 1.4, 1.6, 1.8, 2.0 mm.

[0289] The distance between the center lines of the bus bar electrodes 5a was 49.3 mm, the length of finger electrodes from one end to the other end of the substrate (including the wi...

example 2

[0297] The relationship between the configuration of the surface electrode and the characteristic was investigated on a bulk-type crystalline silicon solar cell as the solar cell element fabricated according to the foregoing embodiment.

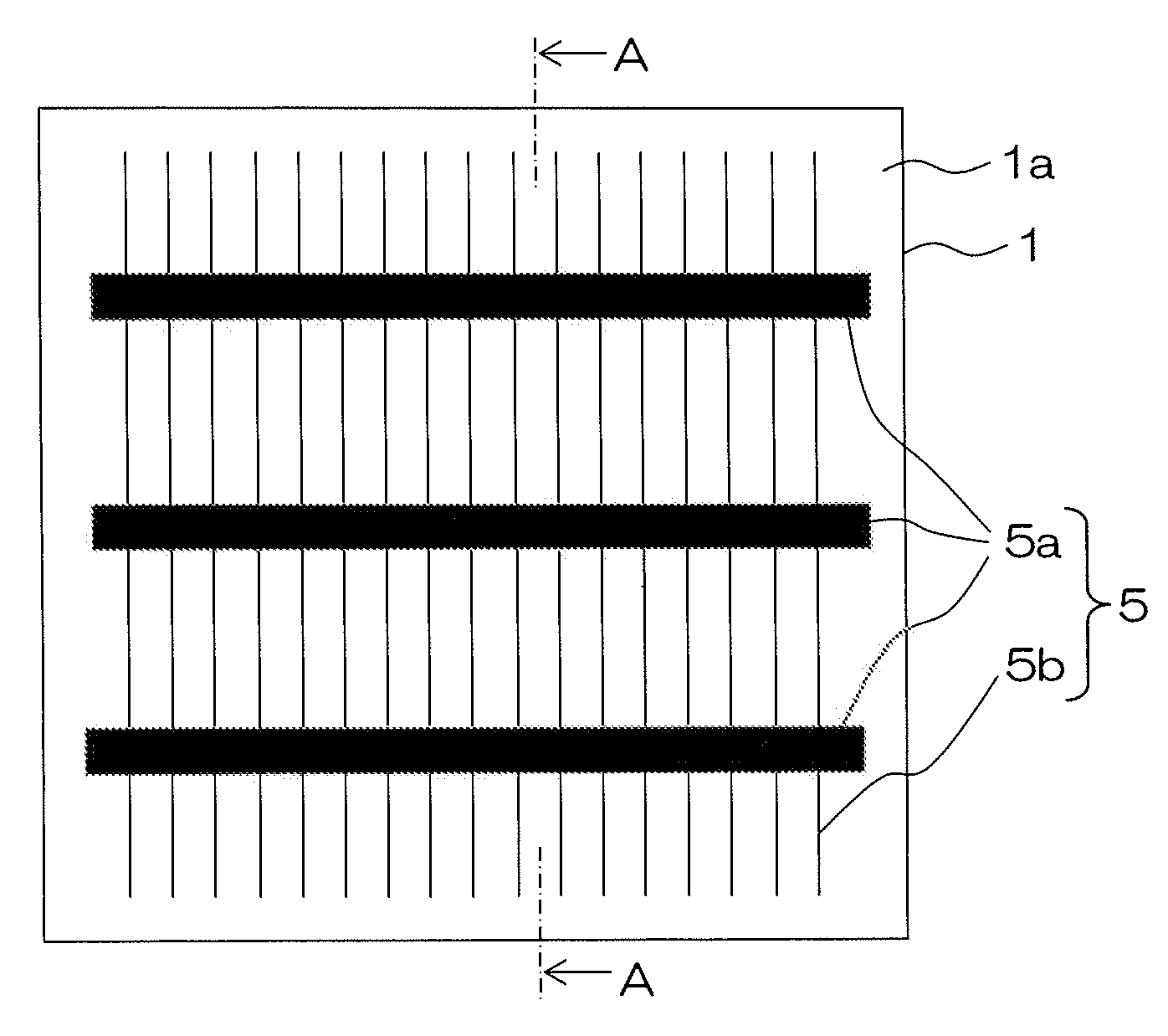

[0298] As the substrate, a flat plate p-type multicrystalline silicon substrate of 150 mm×155 mm in size fabricated by a casting method was used, and solar cell elements with the structure shown in FIG. 4(a) were formed.

[0299] A paste including silver as a main component was printed and baked to form the surface electrode according to the solar cell element of the present invention.

[0300] The pattern for the surface electrode as a whole was formed, such that when the substrate was oriented to have a length of 150 mm in the vertical direction and 155 mm in the horizontal direction in FIG. 4(a), the length of bus bars 5a disposed axisymmetrically to the vertical center line of the substrate was 147.5 mm, the width of the bus bar electrodes 5a is 2 mm...

example 3

[0320] Subsequently, the relationship between the roughness of the contact surface between the surface electrode and the semiconductor substrate and the solar cell element characteristics was examined.

[0321] A flat plate p-type multicrystalline silicon substrate of 150 mm×150 mm in size fabricated by casting was used as the substrate to form a solar cell element with the structure shown in FIG. 1(a).

[0322] A paste including silver as a main component was printed and baked to form the surface electrode according to the present invention. The pattern for the surface electrode as a whole was formed according to the following dimensions. The length of two bus bar electrodes 5a disposed axisymmetrically to the vertical center line of the substrate was 148.8 mm. The width of the bus bar electrodes 5a was 2 mm, the distance between the center lines of two bus bar electrodes 5a was 75 mm, the length of finger electrodes 5b from one end to the other end of the substrate (including the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com