Semiconductor device and method for fabricating the same

a technology of semiconductor devices and interconnections, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of difficulty in further lowering the resistance of the interconnection formed of cu and lowering the yield, so as to reduce the interconnection capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

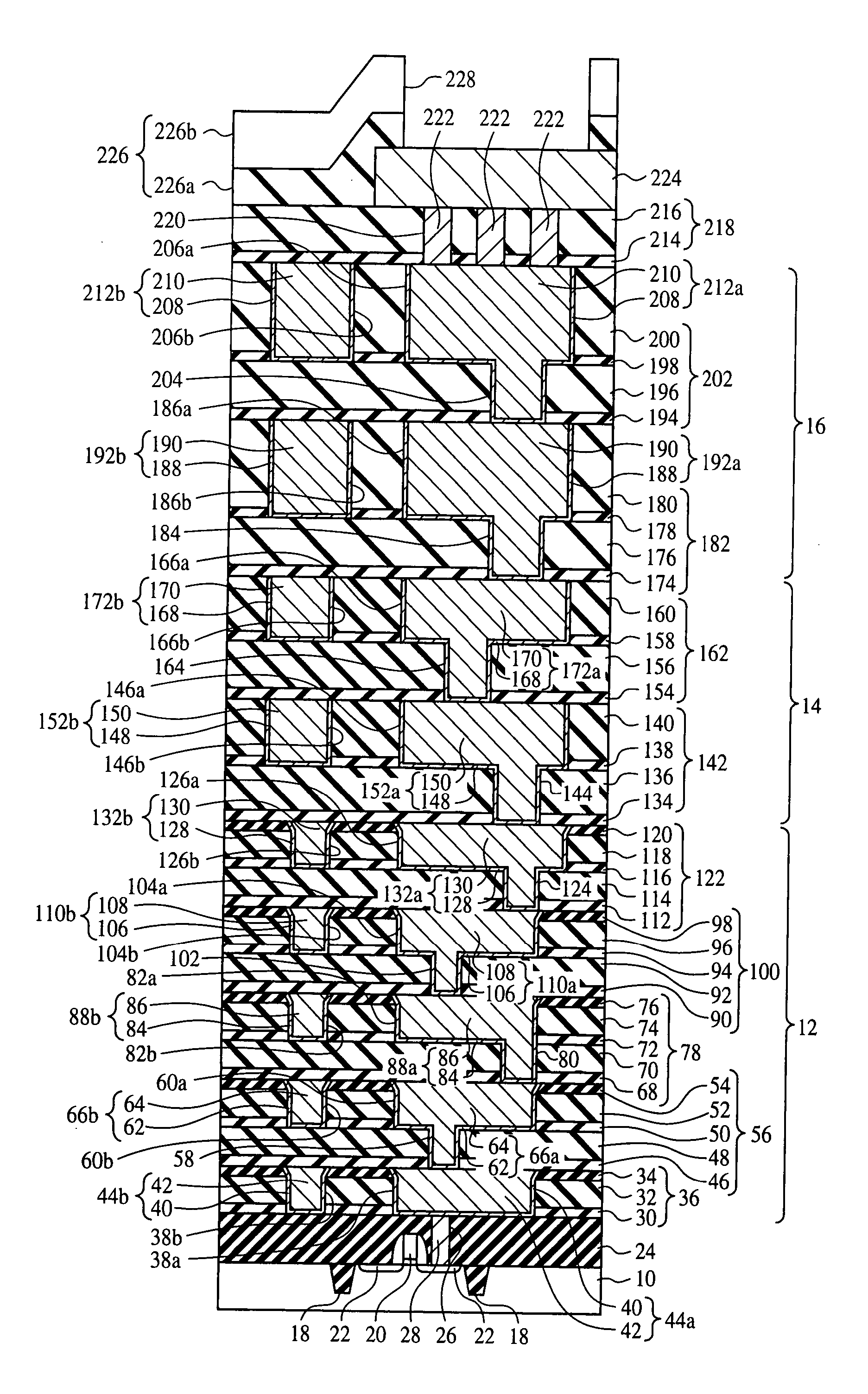

Image

Examples

Embodiment Construction

[0050] In order to decrease the interconnection capacitance of semiconductor devices, as described above, the use of low-k materials as materials of the inter-layer insulation films is being studies. As the low-k materials are known SiOC, SILK (registered trademark) by The Dow Chemical Company, FLARE (registered trademark) by Honeywell Electronic Materials, etc. Most of such low-k materials are water-repellent. This is for the following reason. The relative dielectric constant of water is as high as 88. Accordingly, when a film formed of a low-k material absorbs humidity, the dielectric constant of the film rises. To suppress the dielectric constant increase due to the humidity absorption, the low-k materials are terminated with Si—H, SiCH3 for the processing for prohibiting the formation of Si—OH bonds, which are hydrophilic.

[0051] As mentioned above, in order to suppress the dielectric constant increase due to the humidity absorption, the low-k materials are terminated with hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com