Ozone and Chemical Resistant Coating for Railway Line Elastomeric Components

a technology of elastomeric components and ozone, which is applied in the field of surface coatings, can solve the problems of bending stress, premature failure, and wear of panels, and achieve the effects of improving weatherability, ozone, impact, abrasion and oil resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

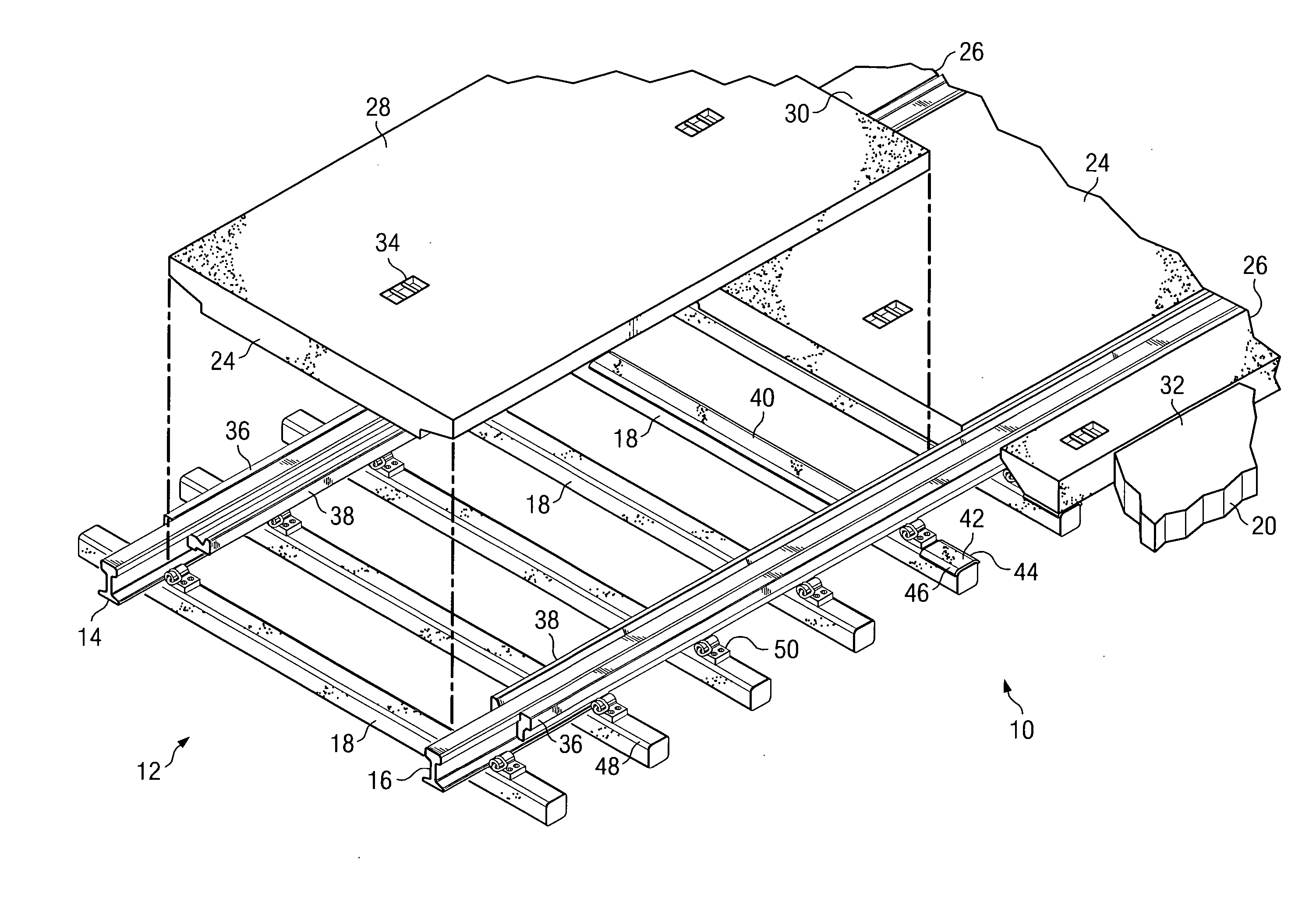

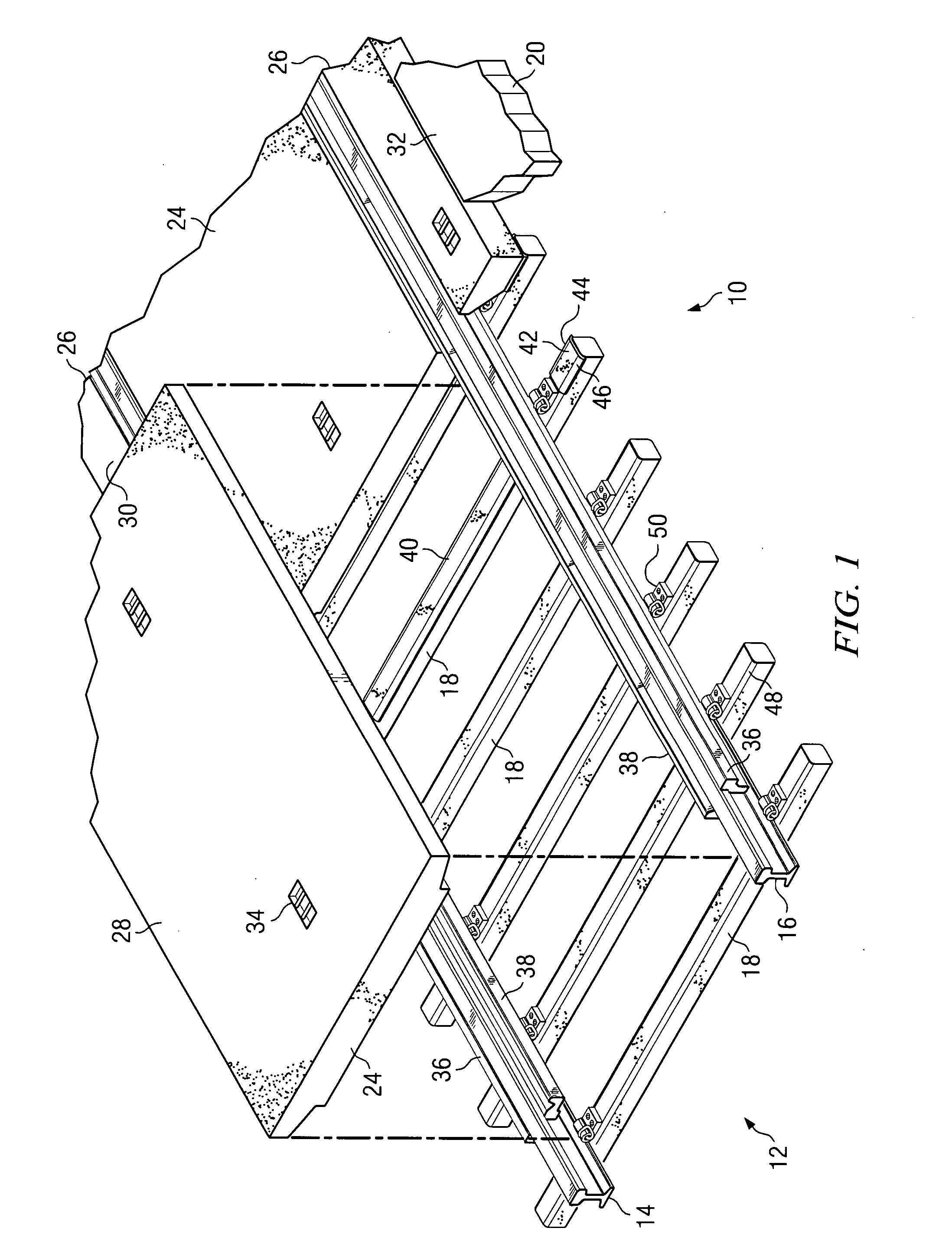

[0023] Referring now to FIG. 1 of the drawings, there is shown a railway grade crossing, designated generally as 10. The crossing 10 includes a railroad track 12 having parallel rails 14, 16 supported on cross ties 18, which are typically set into ballast. The ties 18 are preferably of concrete but could be of wood or other material. A road 20 for vehicular traffic is shown crossing the railway track 12. Concrete filler panels 24 and 26 have respective upper surfaces 28 and 30 located at substantially the same height as the upper surface 32 of the road 20 on either side of the crossing 10. In the particular grade crossing 10 shown in FIG. 1 the road 20 is sufficiently wide such that two wide panels 24 arranged end-to-end are needed between the rails 14 and 16. Similarly, on each side of the track 12 two smaller side panels 26 have been placed end-to-end outside the rails 14 and 16 with their upper surfaces 30 aligned with the road surface 32 of the road 20. In constructing the grade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com