Electronic assembly with detachable components

a technology of electronic components and components, applied in the direction of non-printed jumper connection addition, circuit inspection/indentification, test/measurement of semiconductor/solid-state devices, etc., can solve the problems of difficult removal of soldered or wire-bonded components for repair or reuse, and the cost of sockets is rather high, so as to facilitate the placement of components, eliminate the insertion step of acm, and the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Detailed descriptions of exemplary embodiments are provided herein. It is to be understood, however, that the present invention may be embodied in various forms. Therefore, specific details disclosed herein are not to be interpreted as limiting, but rather as a basis for the claims and as a representative basis for teaching one skilled in the art to employ embodiments of the present invention in virtually any appropriately detailed system, structure, or manner.

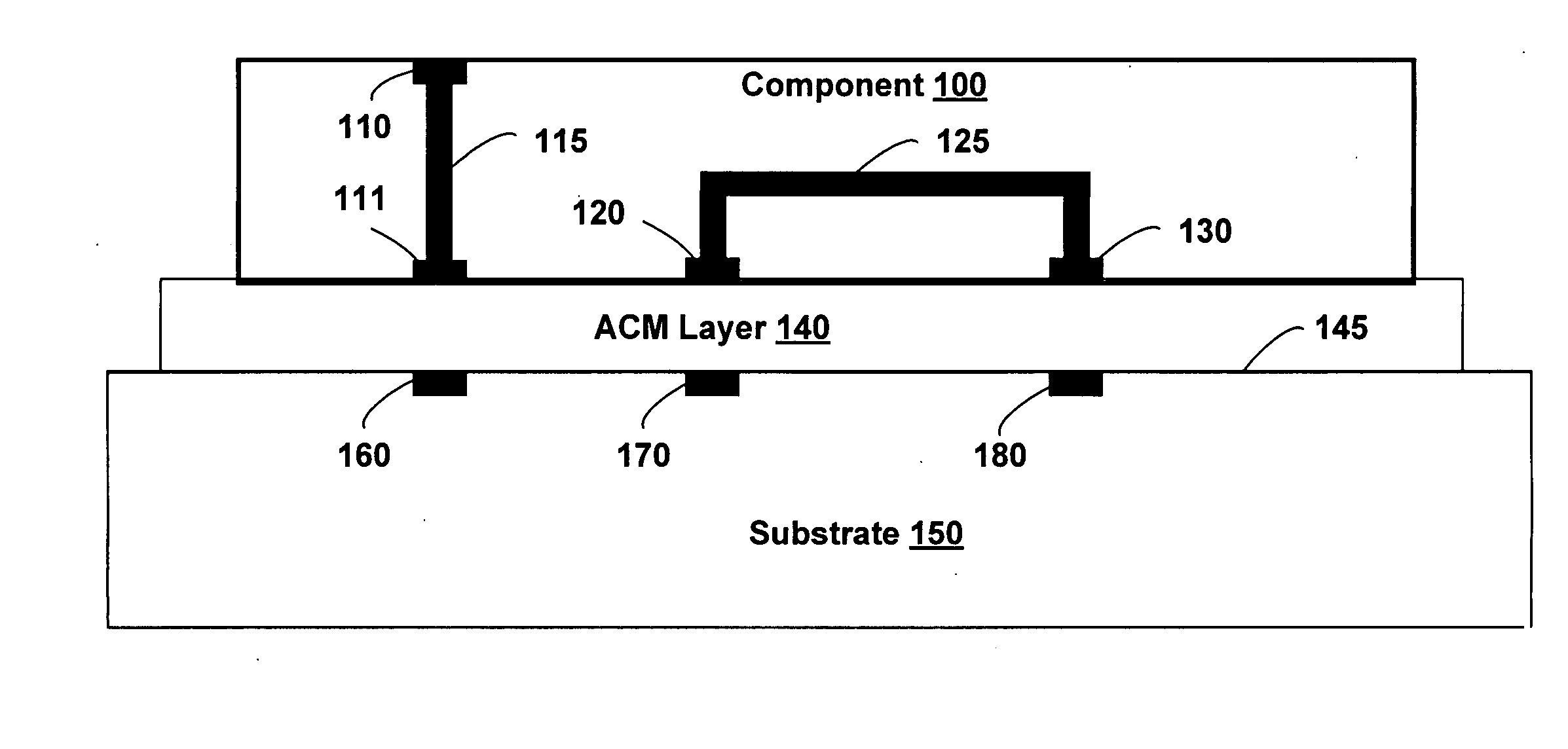

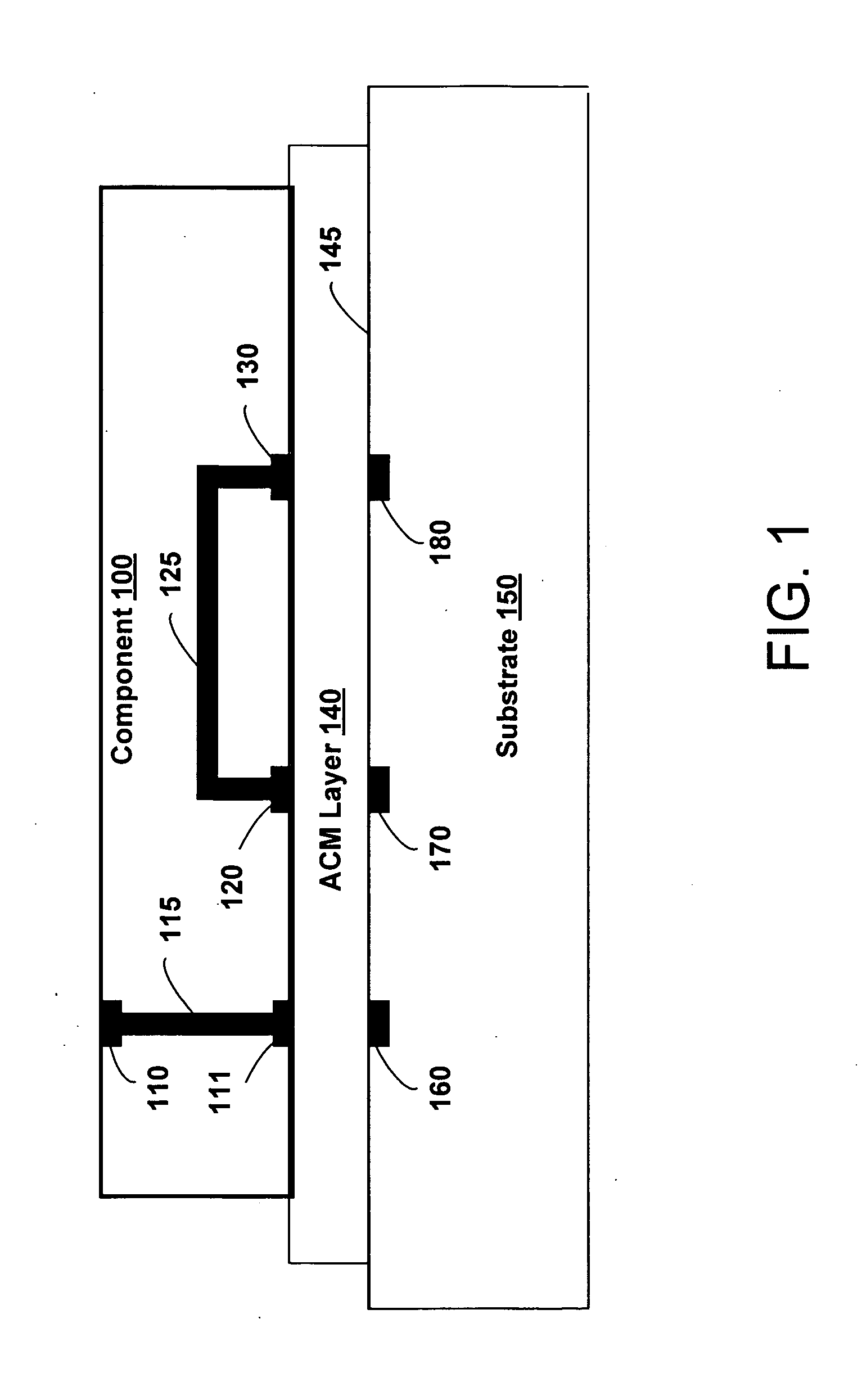

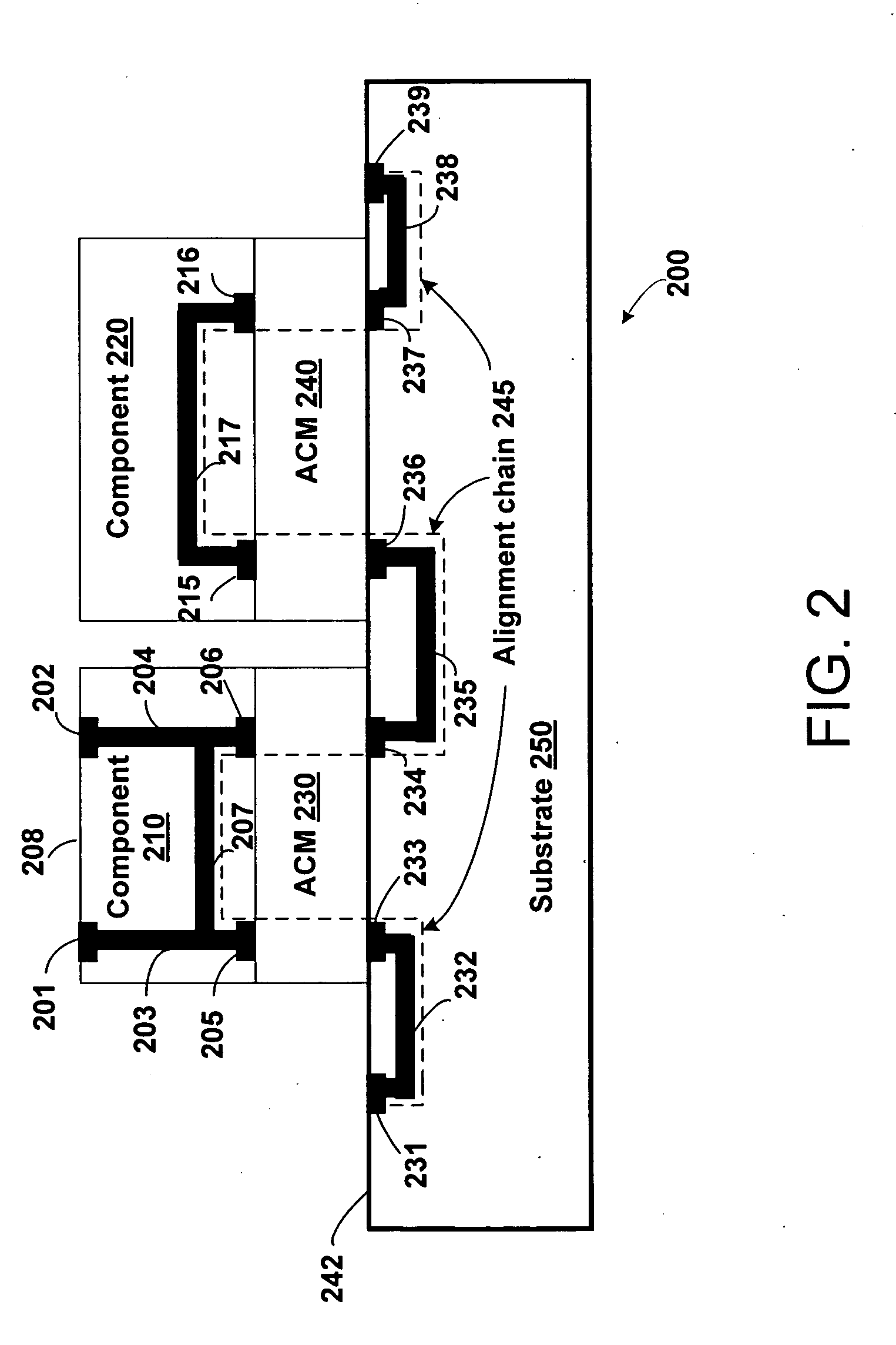

[0024]An exemplary embodiment is an electronic assembly comprising detachable components assembled on a substrate via an anisotropic conductive material as an interconnect layer. The electronic assembly may comprise alignment chains to monitor positional and contact integrity of components on the substrate across the interconnect layer comprising the anisotropic conductive material.

[0025]Electronic assemblies, such as flash cards, add-on boards, or memory modules, have components soldered or wire-bonded on substrate, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrically | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

| thermal dissipation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com