Semiconductor device and method of manufacturing the same

a technology of semiconductors and semiconductors, applied in the direction of printed circuit manufacturing, printed circuit aspects, printed element electric connection formation, etc., can solve the problems of connection failure between protruding electrodes and interconnections, downsizing pads, etc., to prevent heat diffusion and prevent substrate deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The embodiments of the present invention will next be described.

[0064] In all the drawings for describing the embodiments, like members of a function will be identified by like reference numerals and overlapping descriptions will be omitted.

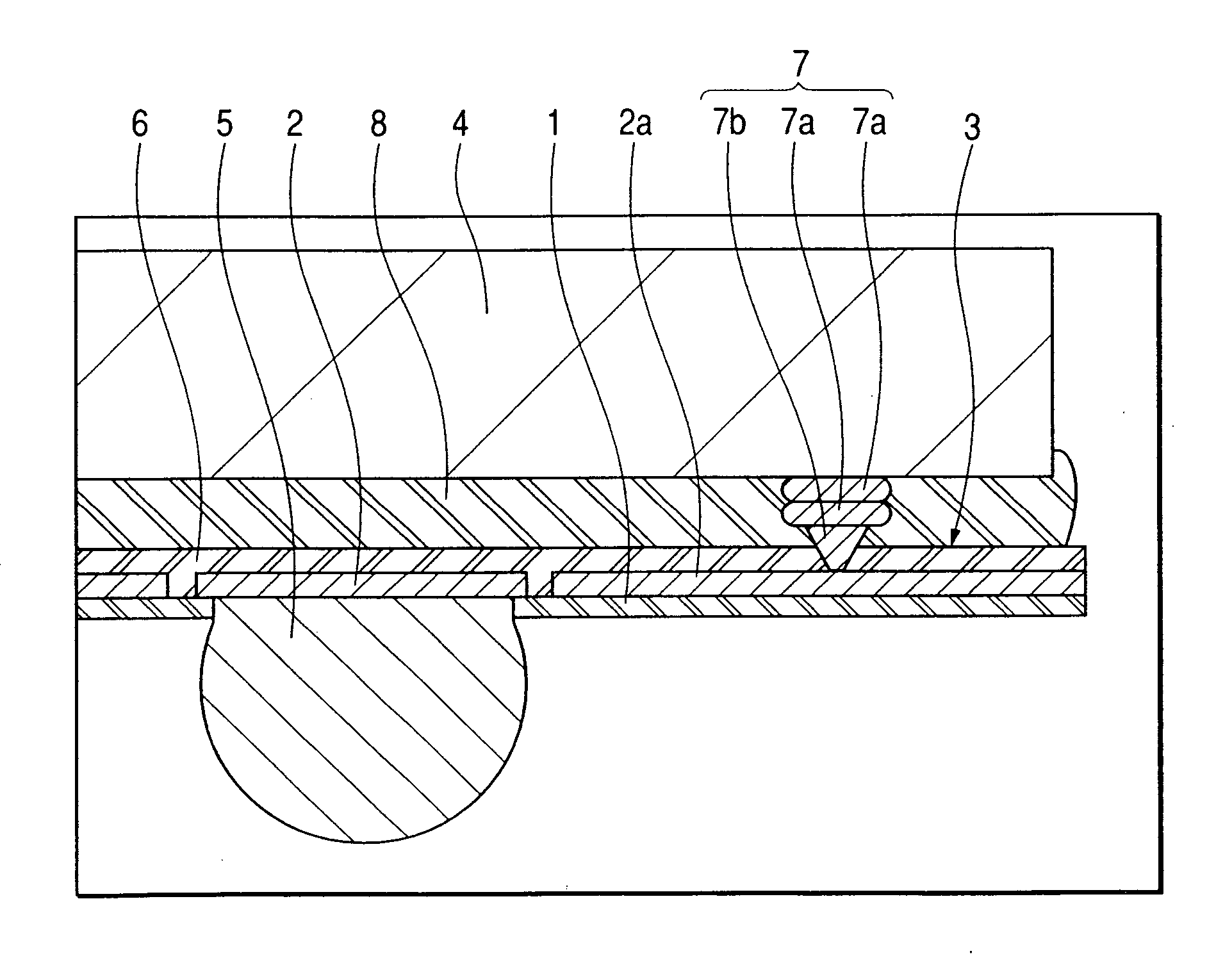

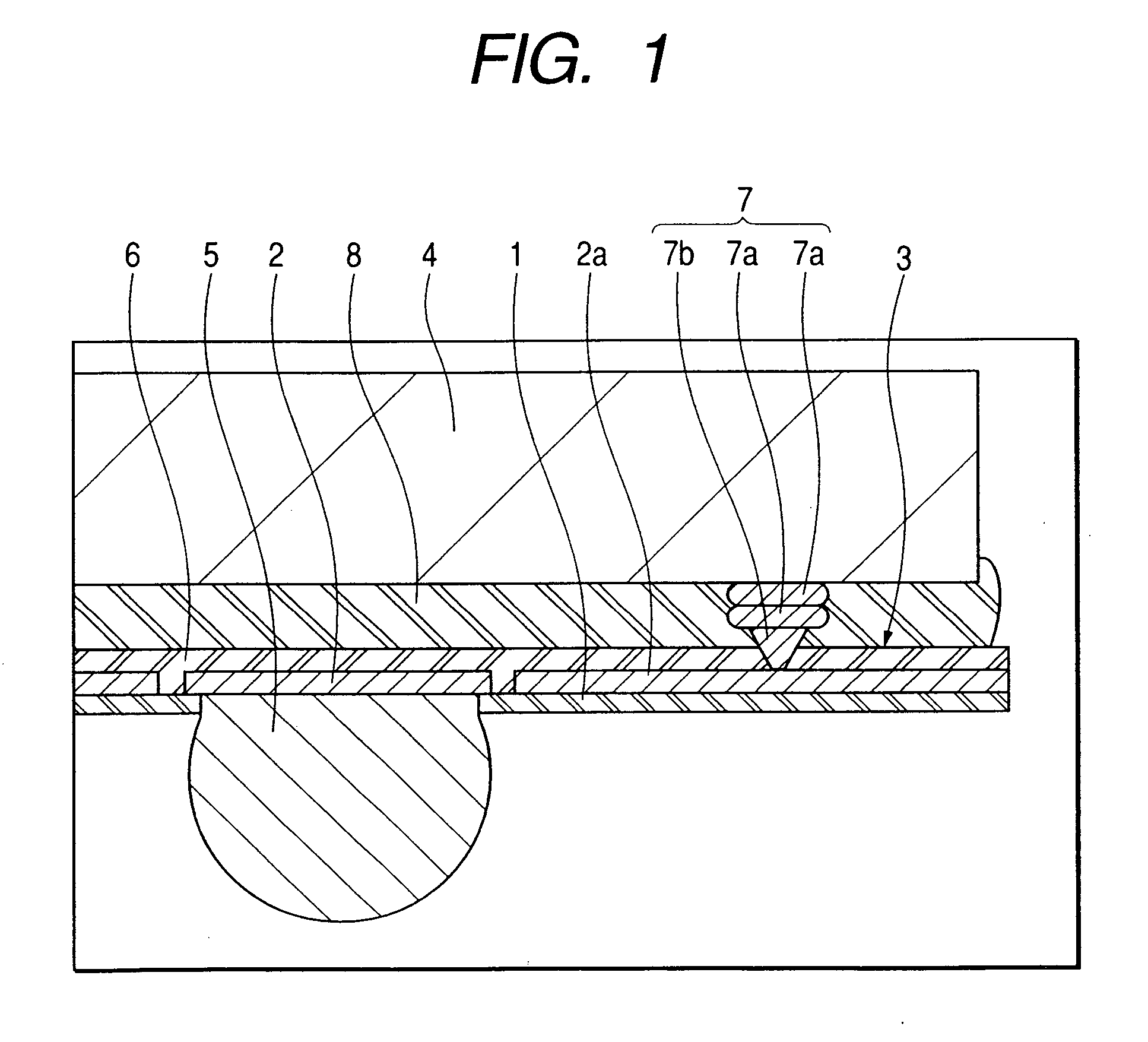

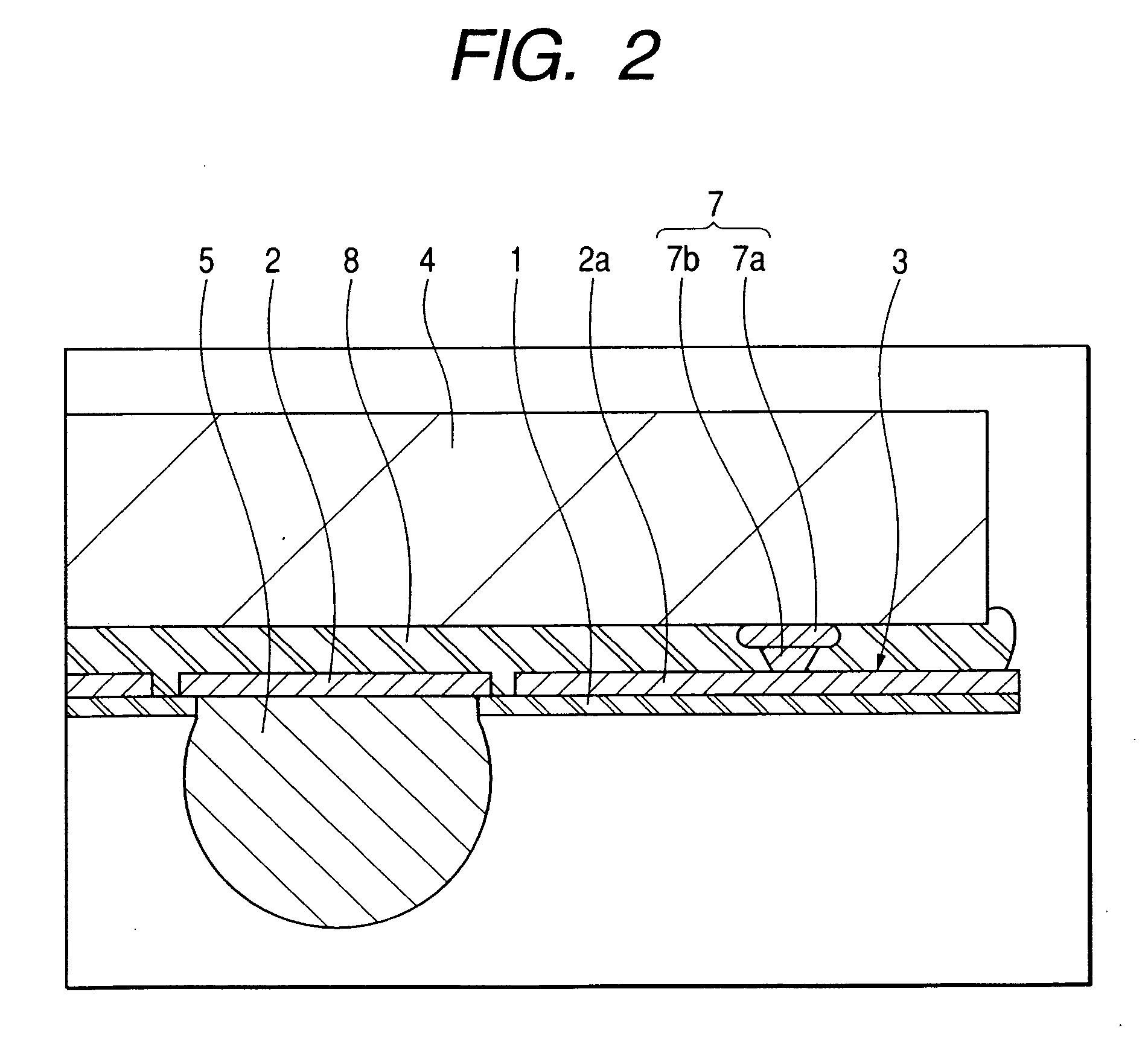

[0065]FIG. 1 is a fragmentary longitudinal cross-sectional view of a semiconductor device according to one embodiment of the present invention.

[0066] In the semiconductor device of this embodiment, a semiconductor chip 4 is mounted on one side of a tape substrate 3 having an interconnect 2 made of a metal film such as copper formed over a base 1 which is a flexible film made of an insulating resin such as epoxy resin, aramid resin or polyimide resin; and a bump electrode 5 such as solder, which will serve as an external terminal of the semiconductor device and is used for connecting with a mounting substrate, is formed over the other side. The semiconductor chip 4 is connected to one end of the interconnect 2 formed over the tape substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com