Use of expanded constituents and manufacture of products therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0098] A comparative test will be described, wherein products made according to the invention, using expanded particles as feedstock, are compared with products produced using unexpanded particles as the base feedstock.

[0099] Rice Krispies® were selected as the expanded feed constituent of the present invention. Whole grain rice was to be the comparative non-expanded constituent. Glycerol and water constituted the molecules able to establish hydrogen bonds.

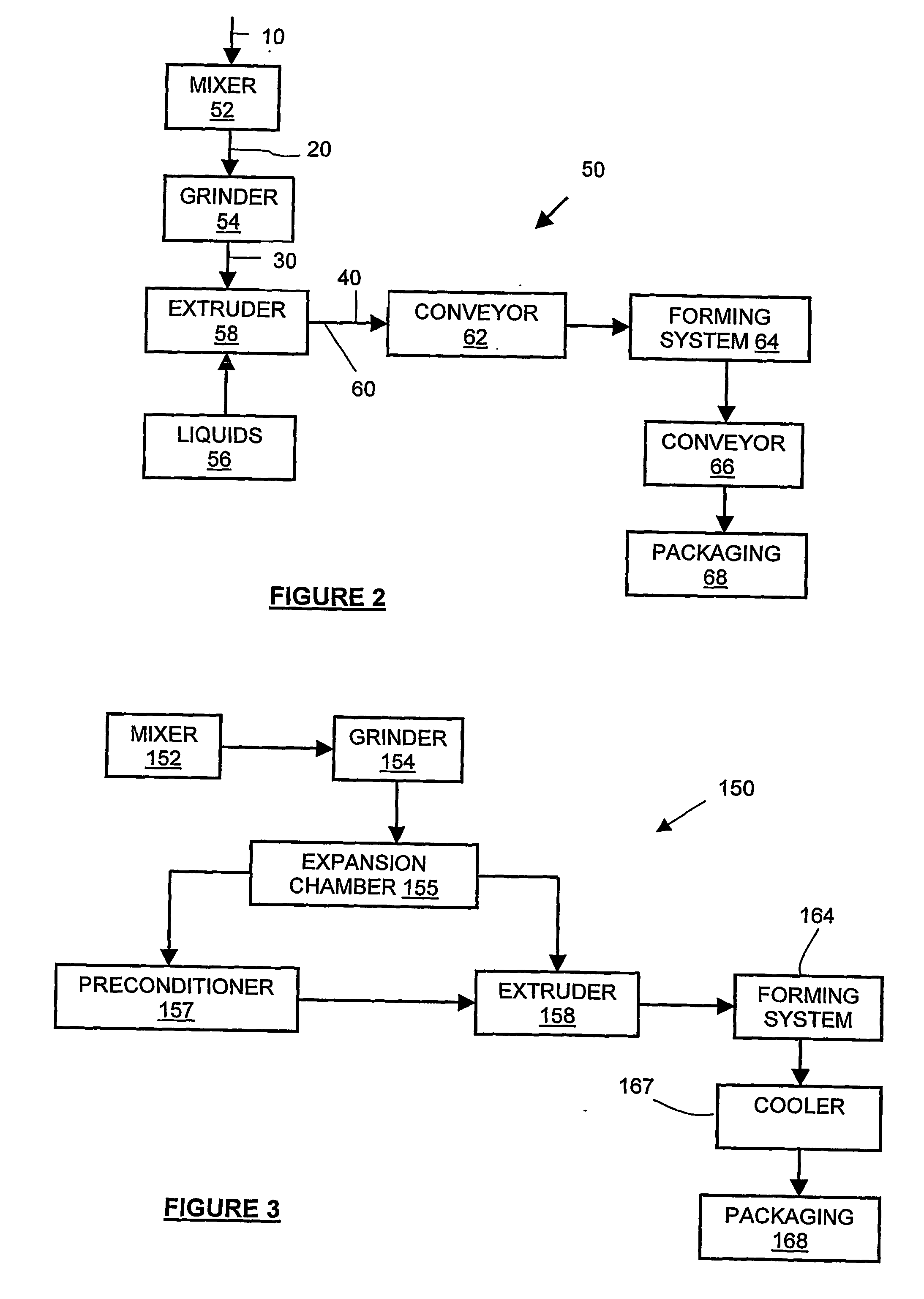

[0100] For purposes of simplicity the dry constituents are tabulated in Table 1 and liquid additives in Table 2. Extrusion is selected as the cooking method and extrusion parameters (mechanical energy input level, die pressure and amperage) for determining the various product runs are presented in Table 3.

[0101] Each of the products was made by selecting a dry constituent composition 1 or 2, processing it in an extruder 58 under a set of extrusion parameters set out in table 3 and injecting a liquid component blend A or B selec...

example 2

[0118] In Example 2, the digestibility of a product 40, made according to the present invention, was tested. The product was made by extrusion using the recipe of constituents presented in Table 6 and with injected liquids mixture A of Table 2. The extrusion conditions are the same as given in Table 3 of Example 1.

TABLE 6Product 3AINGREDIENTSPRODUCT 3AGround Rice Krispies ®87.5% Gelatin 100 Bloom6%Potassium sorbate0.3% Dicalcium phosphate5.2% Nutrient mixture1%Total100%

[0119] Eight adult beagle dogs (4 female, 4 male) in good health were individually housed and fed once per day with a test diet.

[0120] The eight dogs were fed a diet that was a combination of the products 40 of the present invention and commercial canned pet food (Winalot—a trade mark of Societé des Produits Nestlé). These foods were the sole source of nutrition for the animals for the duration of this trial. The daily energy ration for each of the dogs was calculated based on its daily metabolic energy (ME) re...

example 3

[0135] In Example 3 the chewing duration of products of the present invention was tested using a fixed group of forty dogs. The products were produced according to the parameters of Tables 1, 2 and 3. The products tested were those designated 3A and 4A and a commercial product branded as Jumbone (100 g / Small Dogs), available from Pedigree Masterfoods, Melton Mowbray, UK. These products were formed using circular dies of 25 mm diameter and divided into rods about 130 mm in length.

[0136] A veterinarian screened all participating dogs before the trial commenced, to ensure each dog was in good oral health and presented with no oral defects, such as gingivitis, bleeding and / or redness of gums, missing teeth, etc. The test dogs covered a broad range of sizes.

[0137] The dogs were presented with the products 3A, 4A and the comparative Jumbone product and their eating behaviour, as seen, for example, in the duration of chewing the products, was monitored. With regard to the determination o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com