Ion gun deposition and alignment for liquid-crystal applications

a technology of liquid crystals and aligned atomic structures, applied in the direction of vacuum evaporation coatings, instruments, transportation and packaging, etc., can solve the problems of reducing the process yield, affecting the quality of the rubbing process, and the choice of materials suitable for the rubbing process is limited, so as to reduce the potential contamination of the surface, simple and cost-effective, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

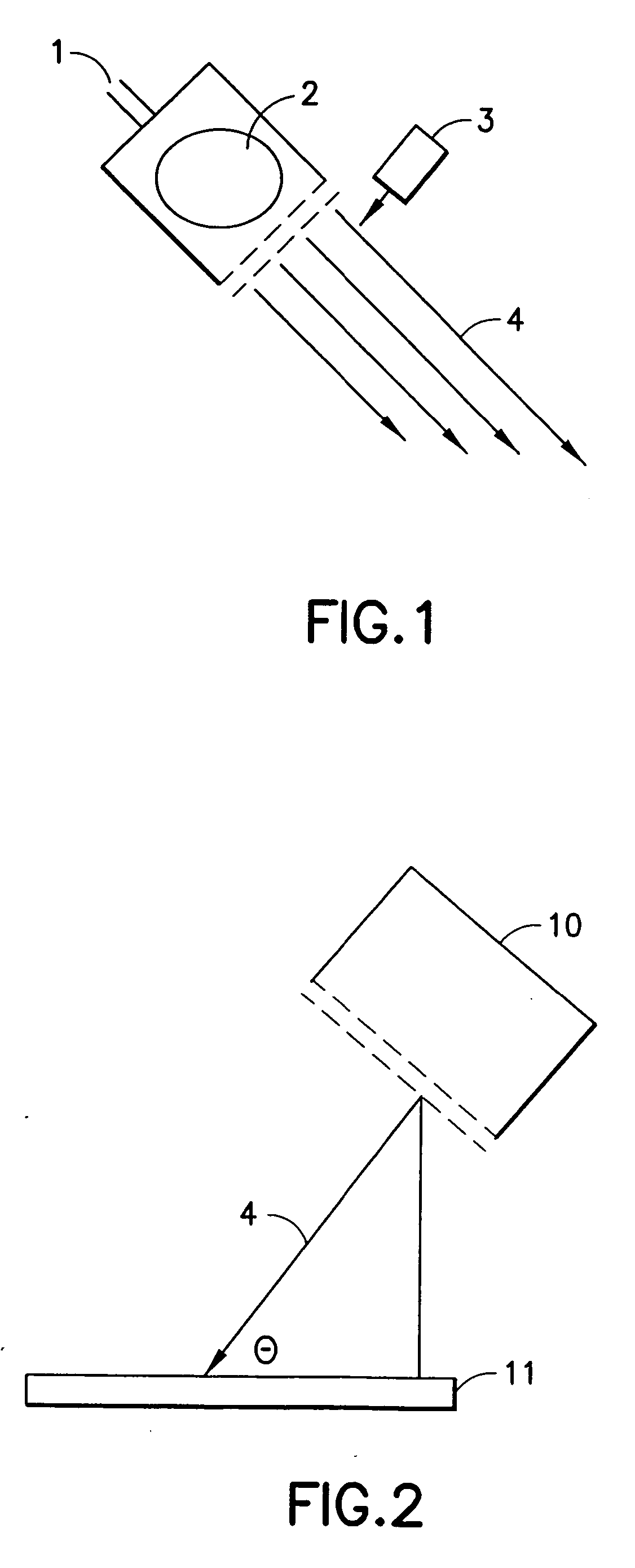

[0045] In a second embodiment, one or more ion sources can be held in a fixed position while the substrates to be coated with the aligned amorphous film are moved beneath the ion sources. In this embodiment, substrates larger than the ion sources can be processed.

third embodiment

[0046] In a third embodiment, the substrate or substrates to the processed are held stationary whereas the ion sources are moved relative to the substrates. Once again in this embodiment, the movement of the ion sources allows for the processing of substrates that are larger than the ion sources.

fourth embodiment

[0047] In the apparatus either the substrates or the ion sources are capable of movement, but the angle of incidence of the ion sources relative to one another can be the same or different. Thus, the angle of incidence of the ion sources relative to one another can be fixed for the duration of the process or it can be variable, i.e., changed during the processing of the substrates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com