Novel infrared dry blanching (IDB), infrared blanching, and infrared drying technologies for food processing

a technology of infrared drying and infrared blanching, which is applied in the field of food processing, preparation, and preservation, can solve the problems of comparable initial capital cost of infrared equipment needed for the idb process, and achieve the effects of preserving nutrients, flavor, and flavor, and reducing the cost of infrared equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples and experiments

[0057] A Catalytic flameless gas-fired (CFG) infrared emitter from Catalytic Infrared Drying Technologies LLC (Independent, Kans.) was used for these experiments. Other types of infrared emitters or heaters may also be used to generate the required medium and far infrared radiant energy. For comparison, control samples were produced by using a steam blancher and conventional heated air dryer. Various food products such as pears, baby carrots, cut sweet corn and sliced potatoes were used in these experiments to study the effectiveness of IDB.

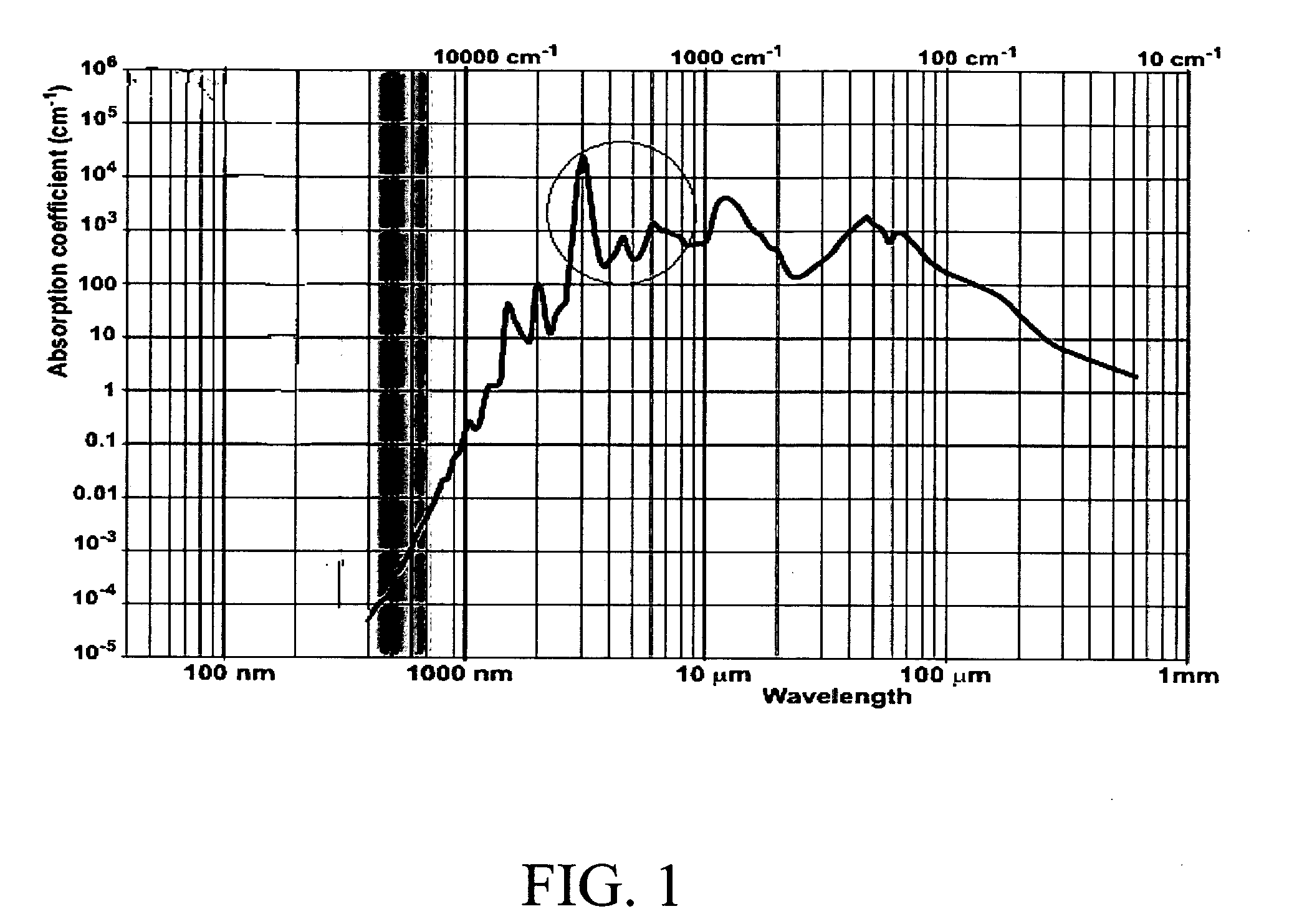

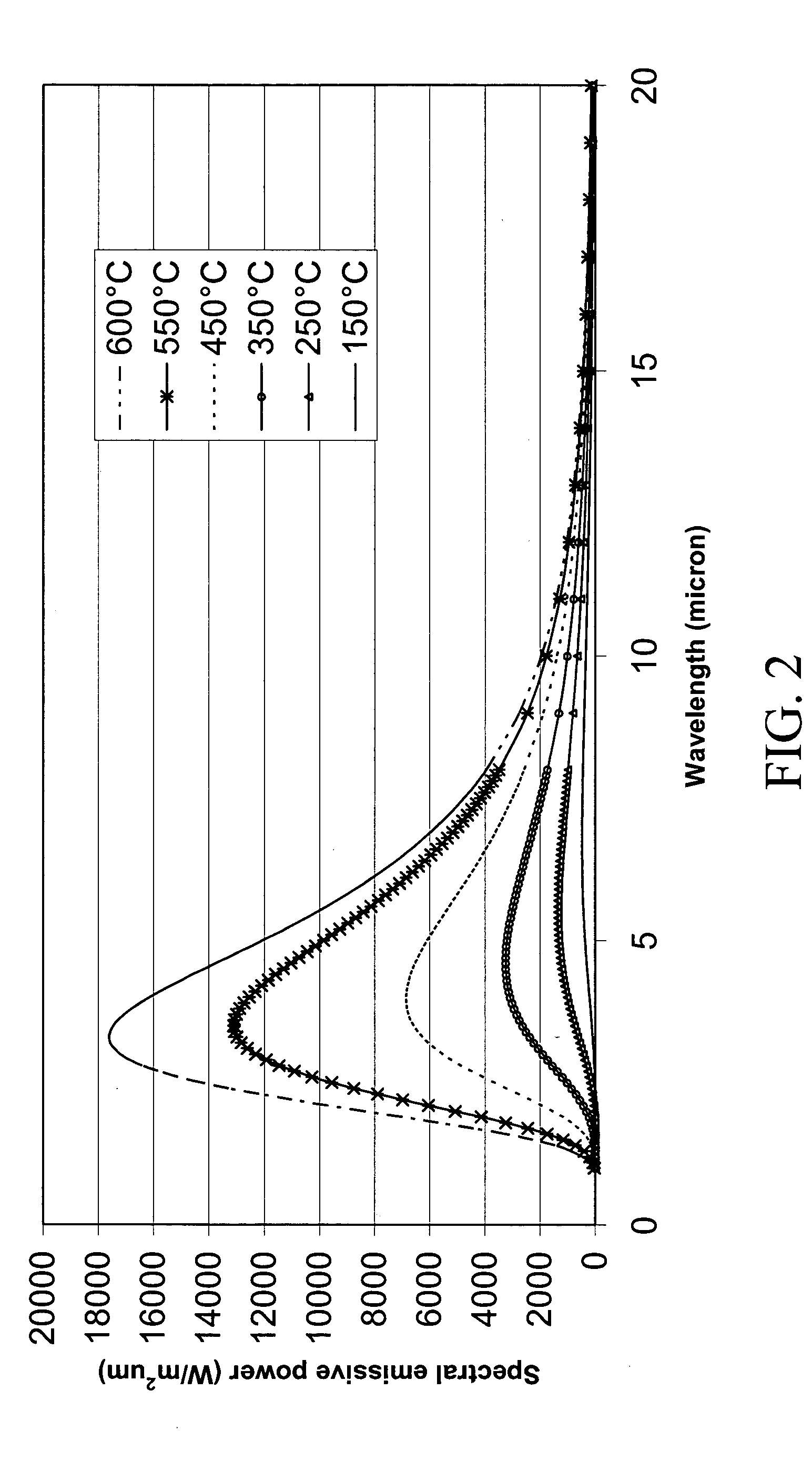

[0058] The CFG infrared emitter used for these experiments generated medium and far IR with peak energy from 3.3 to 8 microns, utilizing catalyzed natural gas. A schematic of how the emitter was set up to function as an infrared blancher / dryer is shown in FIG. 3. When combined with air across the catalyst, natural gas reacts by oxidation-reduction to yield a controlled bandwidth of infrared energy. Small amounts of CO2 and water vapor are also p...

experiment 1

ars

[0065] Infrared Dry Blanching (IDB) was compared to conventional steam blanching. Pears were used in the first comparison. Test parameters included energy efficiency, weight reduction (through dehydration), enzyme inactivation, time needed to inactivate enzymes, and final product quality.

[0066] Recently-harvested Bartlett pears were diced into approximately half-inch cubes and all samples were dipped in ascorbic and citric acid solution with specified concentration and time periods (See experiment 3) before the blanching and dehydration, which was to prevent oxidation from occurring.

[0067] To determine a benchmark blanching time with steam, samples of pear cubes were blanched for times ranging from 30 seconds to 10 minutes with 75° C. steam. After each sample was blanched for the appointed time, it was cut into two pieces and tested for enzymatic activity, using as a control a sample that had not been subjected to blanching. In particular, each sample was examined for peroxidas...

experiment 2

d Dehydration of Pears using IDB

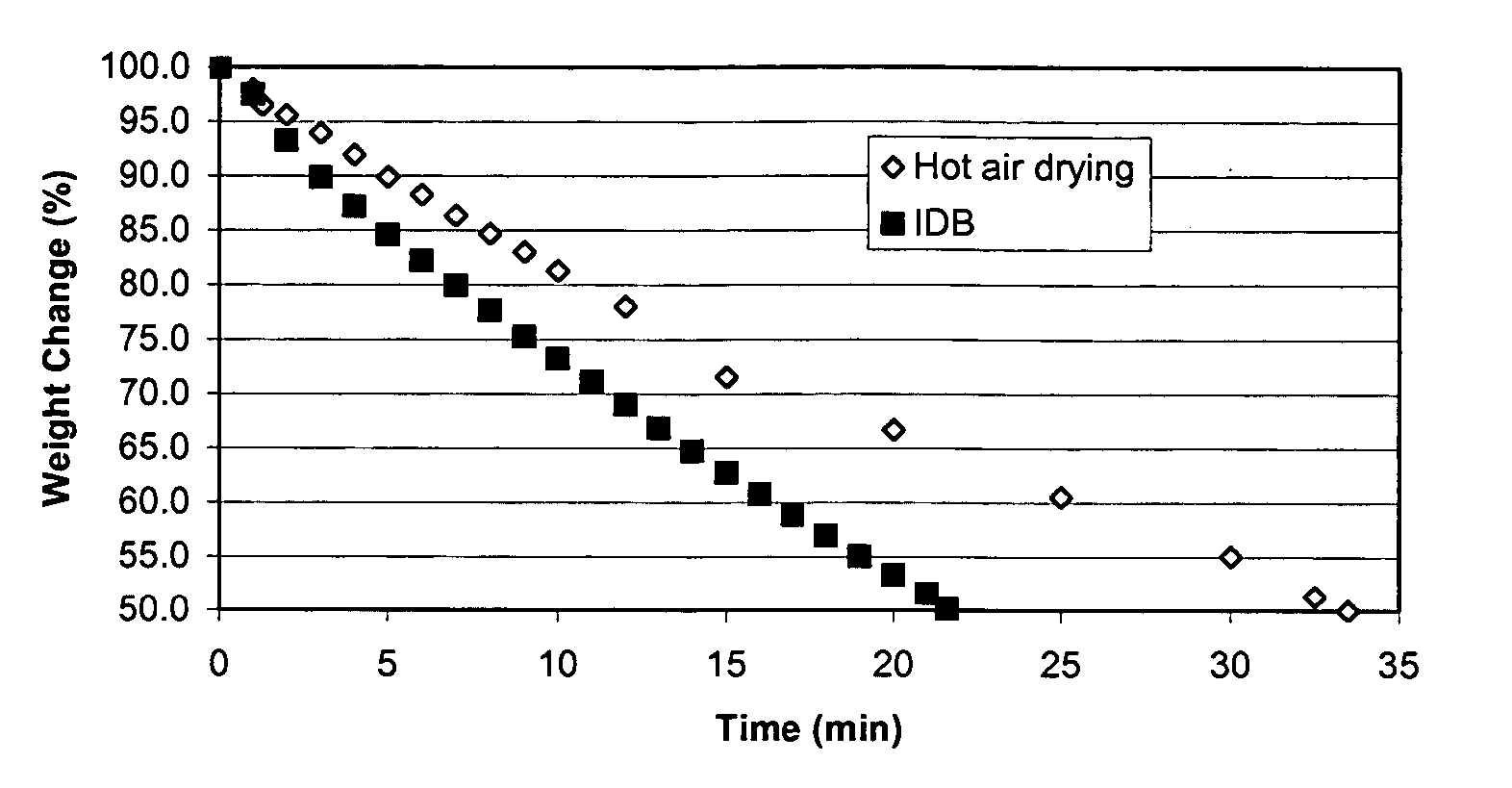

[0077] Pear samples were also subjected to a dehydration study. The conventional method of dehydrating pears is to subject them, after steam blanching, to hot, forced air in order to drive off water vapor. Since steam blanching cannot be used for dehydration processing and IDB can, IDB has a distinct advantage since it can both blanch and dehydrate in a single step.

[0078] For this experiment, fresh (wet) pear samples were dehydrated using both conventional hot air drying and IDB. Dehydration was conducted until a 50% weight reduction was achieved. The drying rates and weight losses of pears were determined using an automatic weight data acquisition system developed in the researchers' laboratory.

[0079] The temperature setting of the IDB emitter was critical to the outcome of the test. The surface temperature of heater / emitter was measured by using temperature sensors preinstalled in the emitter. The optimum conditions for achieving blanching followe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com