Window type probe, plasma monitoring device, and plasma processing device

a monitoring device and window-type technology, applied in the direction of plasma technique, vacuum evaporation coating, coating, etc., can solve the problems of increased cost, increased installation space, undesirable characteristics of electric elements provided on the substrate to be processed, etc., and achieve the effect of simplifying the apparatus structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

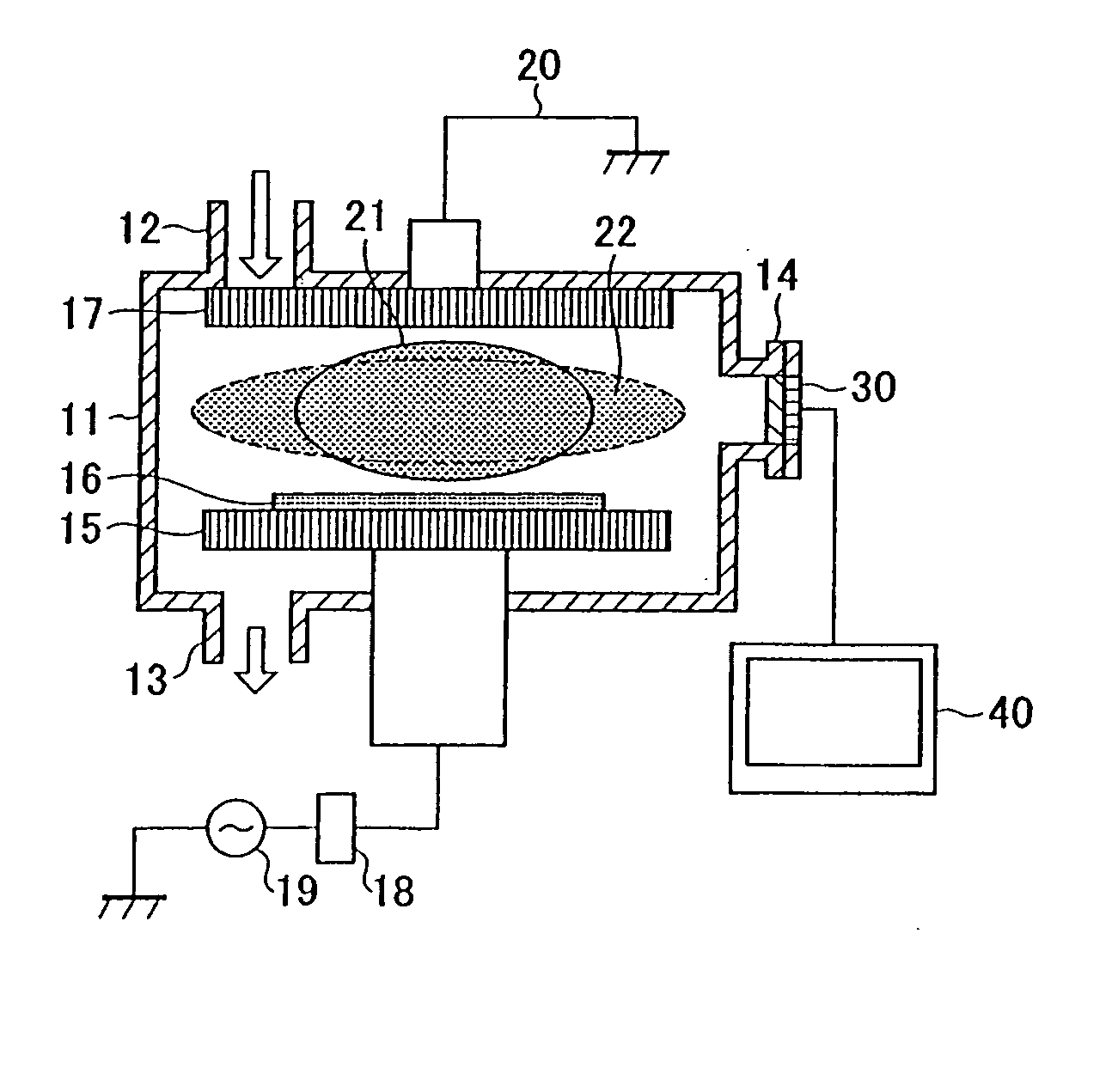

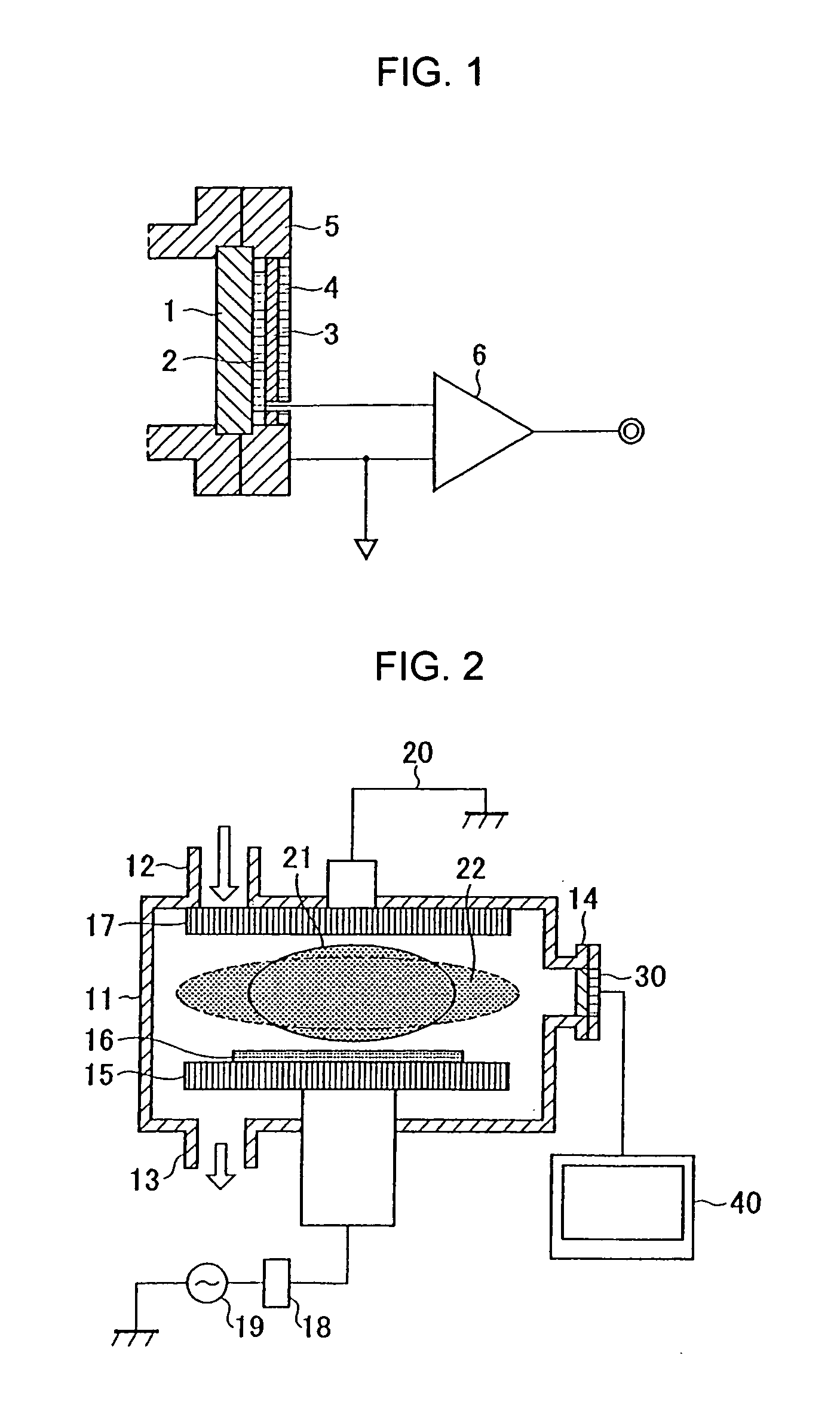

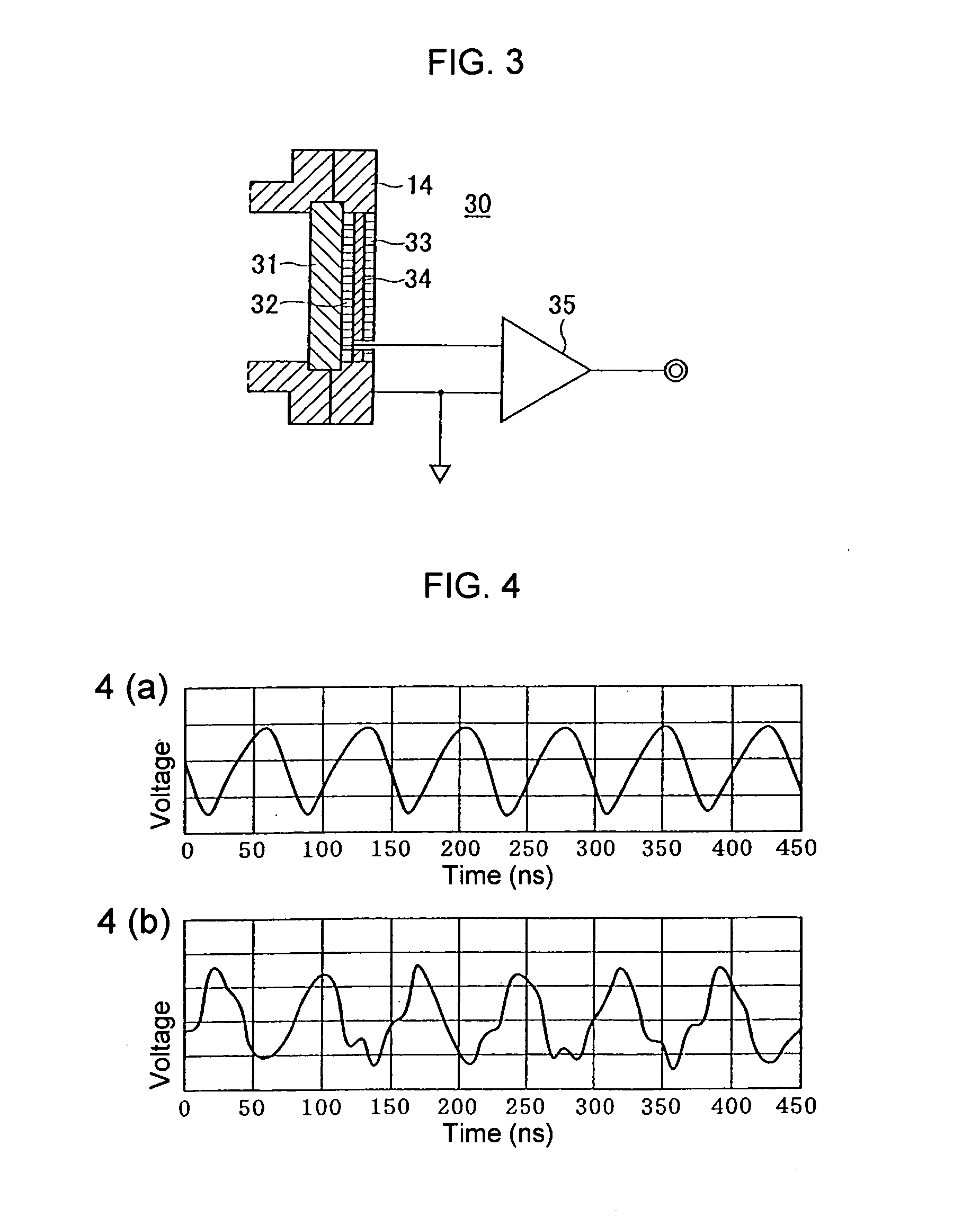

[0046] Hereinafter, a plasma processing apparatus with a detection port type probe and a detection signal processing method according to this invention will be described with reference to FIGS. 2 to 7.

[0047] Reference is made to FIG. 2.

[0048]FIG. 2 is a schematic block diagram showing the plasma processing apparatus with the detection port type probe according to the first embodiment of this invention.

[0049] This plasma processing apparatus is constituted of a process chamber 11 having a gas inlet 12, an outlet 13, and a probe mounting portion 14, a parallel flat plate type electrode disposed inside the process chamber and having a lower electrode 15 on which a Si wafer 16 is placed and an upper electrode 17 used also as a shower head for injecting an introduced gas and opposed to the lower electrode 15, a radio frequency power source 19 for applying an RF power of 13.56 MHz via a matching unit 18 constituted of a blocking condenser or the like and performing an impedance matching...

second embodiment

[0101] Next, with reference to FIGS. 8 to 10, a plasma processing apparatus according to this invention, which is provided with the above-described detection port type probe and detects a fluctuation in plasma, anomalous discharge, and so forth, will be described.

[0102] Reference is made to FIG. 8.

[0103]FIG. 8 is a schematic block diagram showing the plasma processing apparatus with an anomalous discharge monitoring device according to the second embodiment of this invention. A basic constitution of the plasma processing apparatus is the same as that of the first embodiment except for using a plasma monitoring device 50 in place of the digital oscilloscope 40 in the detection system, and descriptions for the same parts are omitted.

[0104] The plasma monitoring device 50 is constituted of a detection port type probe 30, an A / D converter 51, a data processing unit 52, a filter processing unit 53, and an anomalous discharge detection unit 54, and so forth.

[0105] By the use of the dat...

third embodiment

[0125] Hereinafter, this invention which uses a unit for determining a position of anomalous discharge will be described with reference to FIG. 11.

[0126] Reference is made to FIG. 11.

[0127]FIG. 11 is a schematic block diagram showing a plasma processing apparatus with an anomalous discharge monitoring device according to the third embodiment of this invention. A basic apparatus constitution is the same as that of the plasma processing apparatus of the second embodiment shown in FIG. 8.

[0128] In the third embodiment, three or more AE sensors 25, 26, and 27 for specifying a position at which anomalous discharge has occurred are attached to an outer wall of a process chamber 11 (see, JP-A-2001-370610, when necessary).

[0129] In this case, three AE sensors are shown.

[0130] Reference is made to FIG. 12.

[0131]FIG. 12 is an illustration of a method for detecting anomalous discharge in the third embodiment of this invention. It is judged whether or not the anomalous discharge has occurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com