Texturing of magnetic disk substrates

a magnetic disk and substrate technology, applied in the field of methods, can solve the problems of difficult to passivate the disk, the magnetic anisotropy of the disk drops, and the magnetic characteristics of the disk to become anisotropic, and achieve the effect of reducing large low frequency texture lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

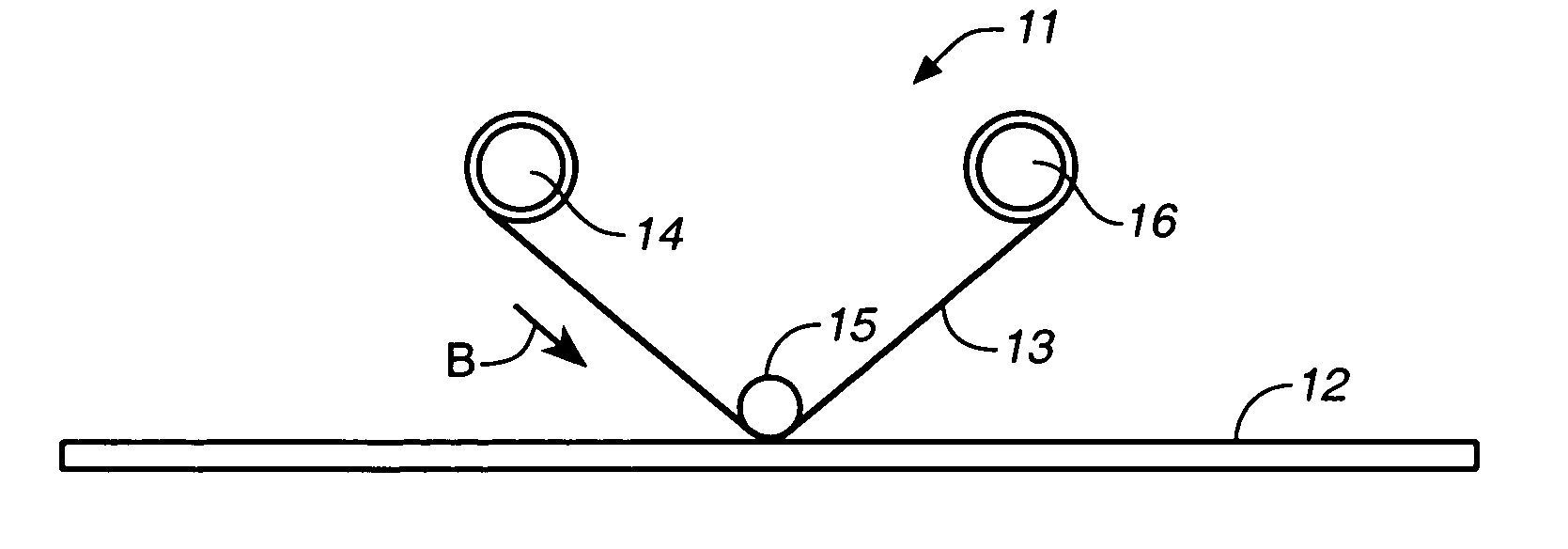

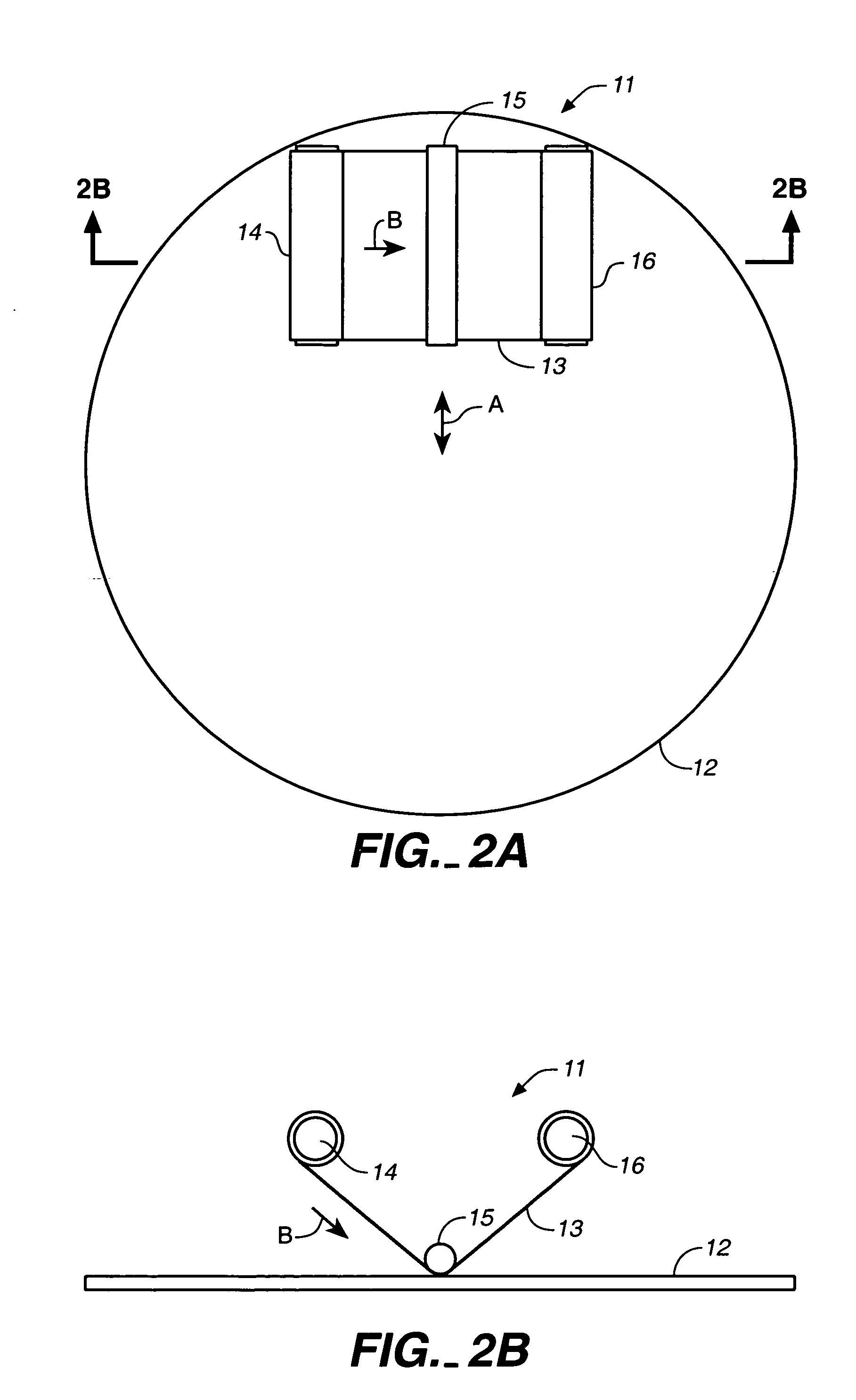

[0022]FIGS. 2A and 2B illustrate apparatus 11 for texturing a substrate 12. (Apparatus 11 is not novel in and of itself.) In FIGS. 2A and 2B, a motor (not shown) rotates substrate 12 while a sheet 13 of material (typically nylon) is pushed against substrate 12. (Sheet 13 moves off of a supply reel 14, around a roller 15, and onto a take-up reel 16 (see arrow B).) Roller 15 urges sheet 13 against substrate 12, e.g. with a force between 1 and 10 pounds. In one embodiment, the force is between 2.5 and 5 pounds. A slurry comprising nano-sized diamond particles (described below) is introduced between sheet 13 and substrate 12. Simultaneously, sheet 13 and roller 15 reciprocate, moving back and forth in a direction A. (Alternatively, substrate 12 can reciprocate instead of sheet 13 and roller 15.) The diamond particles form texture scratches that are non-random, and are in a generally circumferential direction in substrate 12. Because of the motion of sheet 13 and roller 15 in the directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Ra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com