Complex flow-path heat exchanger having U-shaped tube and cantilever combined coil

a heat exchanger and complex technology, applied in heat exchange apparatus, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problems of low heat exchange efficiency and considerable low heat exchange coefficient, and achieve high heat exchange coefficient, small steam flow resistance, and high heat exchange coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

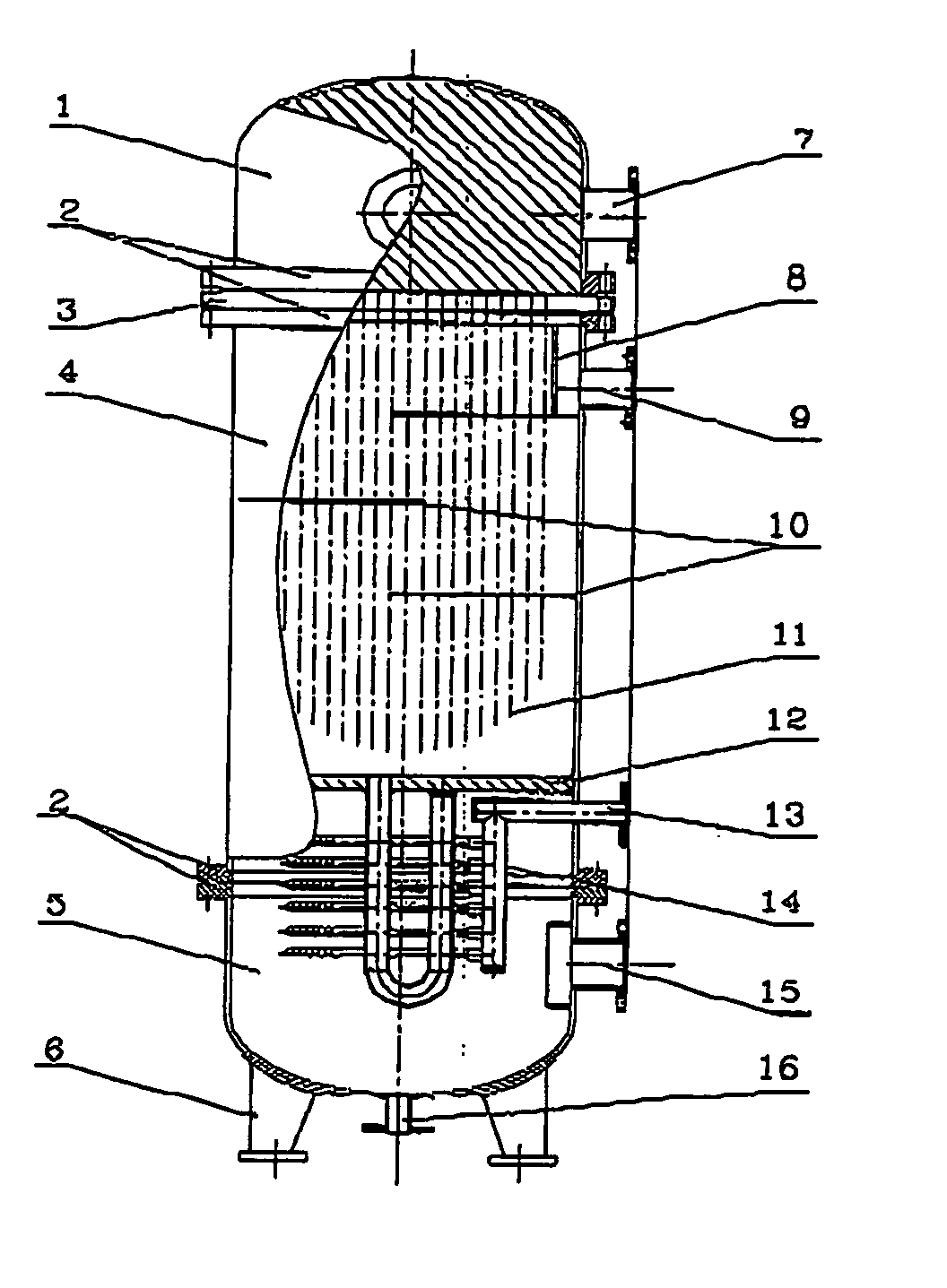

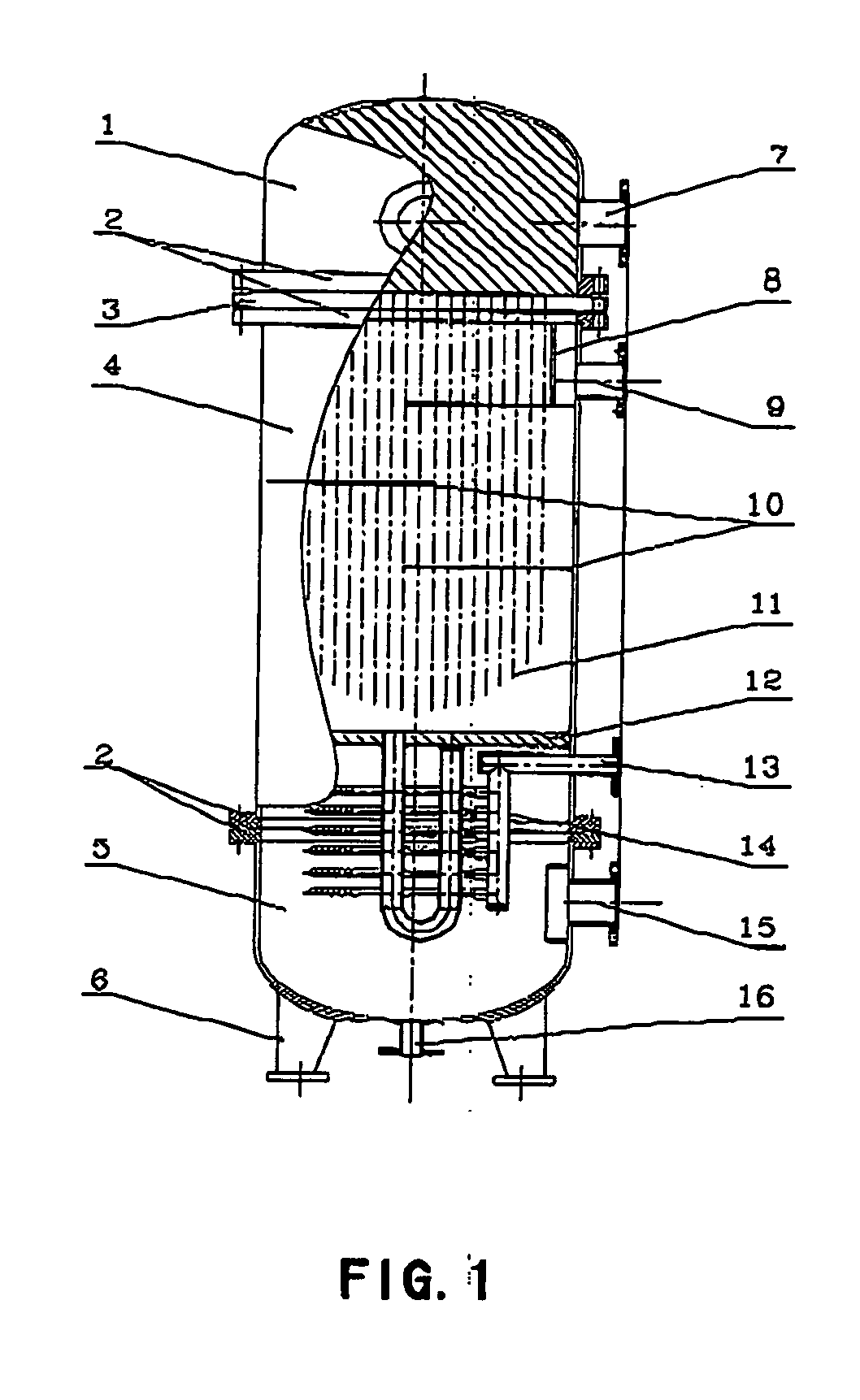

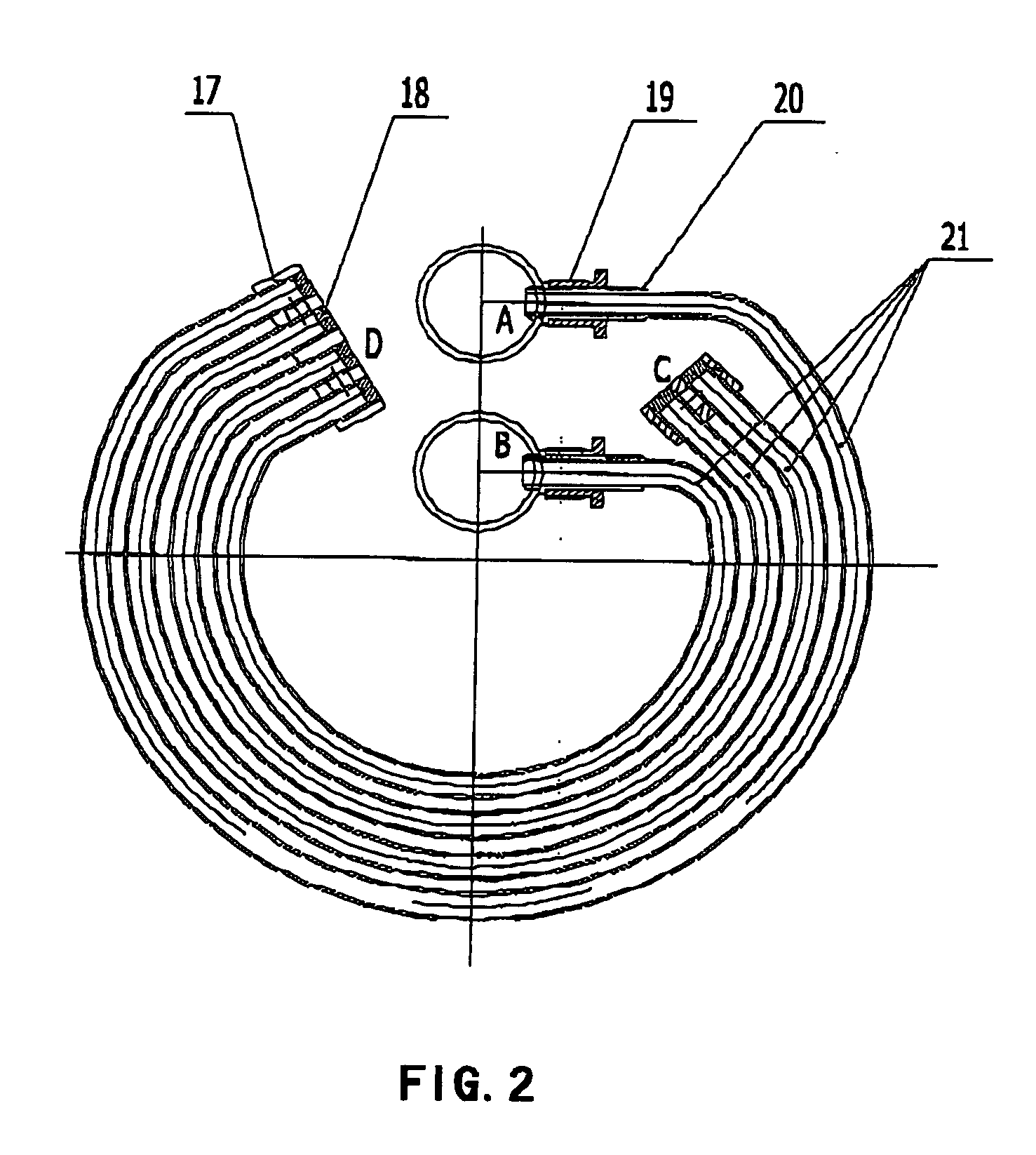

[0013] The embodiments of the present invention will be described as follows. FIG. 1 and FIG. 2 show the construction on the whole. In the heat exchanger according to the present invention arrange vertically, the outlet pipe 7 of the heated water and the inlet pipe 15 of the heated water are disposed on the upper shell cover 1 and the lower shell cover 5 respectively, the steam inlet pipe 9 is disposed on the upper half portion of the cylinder body, and the drainage port 16 and the condensate water outlet pipe 13 are disposed on the lower shell cover.

[0014] The shell body of the heat exchanger is comprised of the cylinder body 4, the flange 2, and the oval shell cover and like. The lower half portion of the cylinder body 4 is provided with the partition plate 12 for dividing the cylinder body 4 into an upper portion and a lower portion, wherein the upper half portion of the cylinder body 4 is provided with the U-shaped tube bundles serving as heat transfer elements, and the lower h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com