Light emitting array with improved characteristics, optical writing unit, and image forming apparatus

a technology optical writing units, applied in the field of light emitting arrays, can solve the problems of preventing the formation of satisfactory picture images, increasing power consumption, and being difficult to achieve, and achieve the effect of improving the quality of picture images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

”

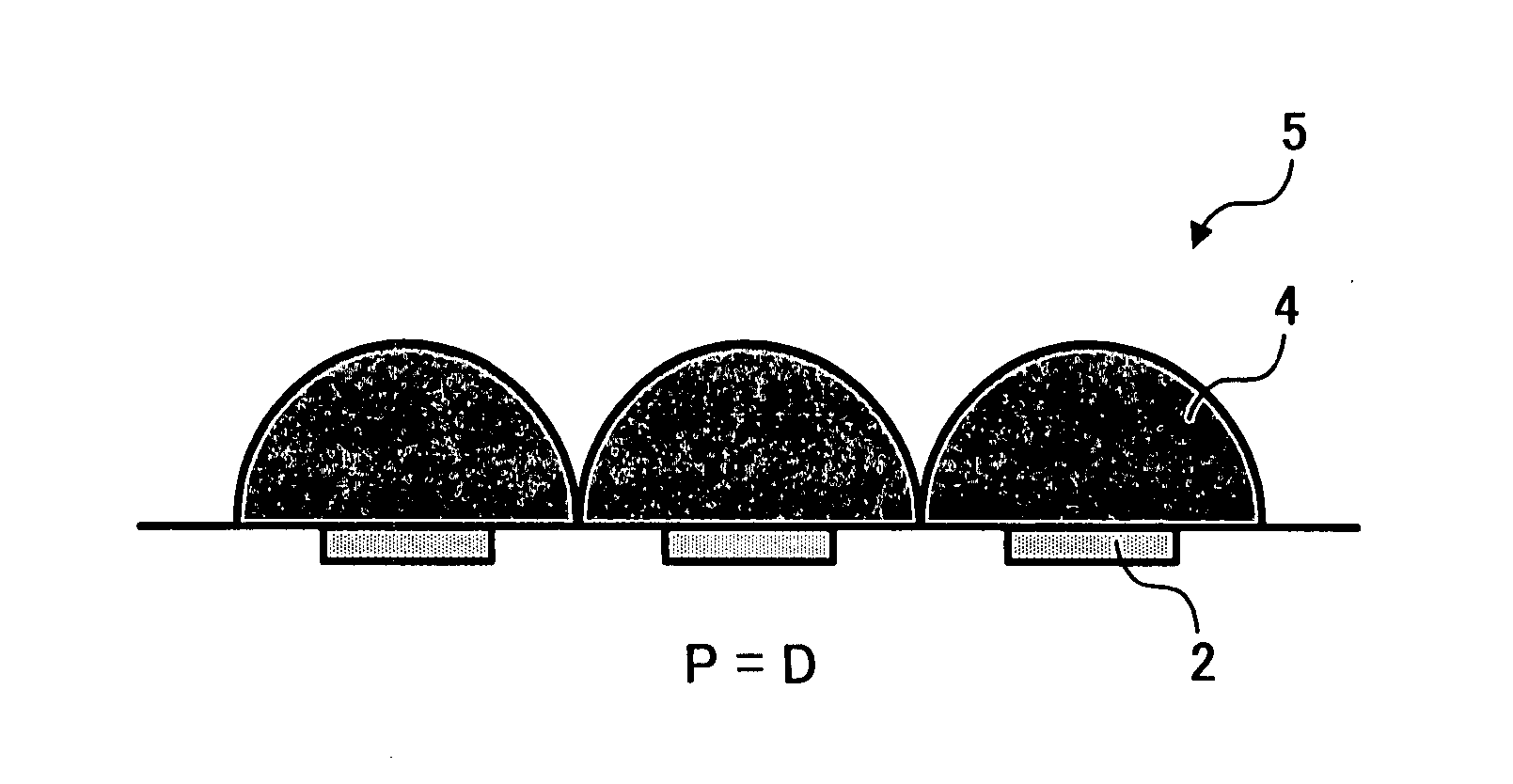

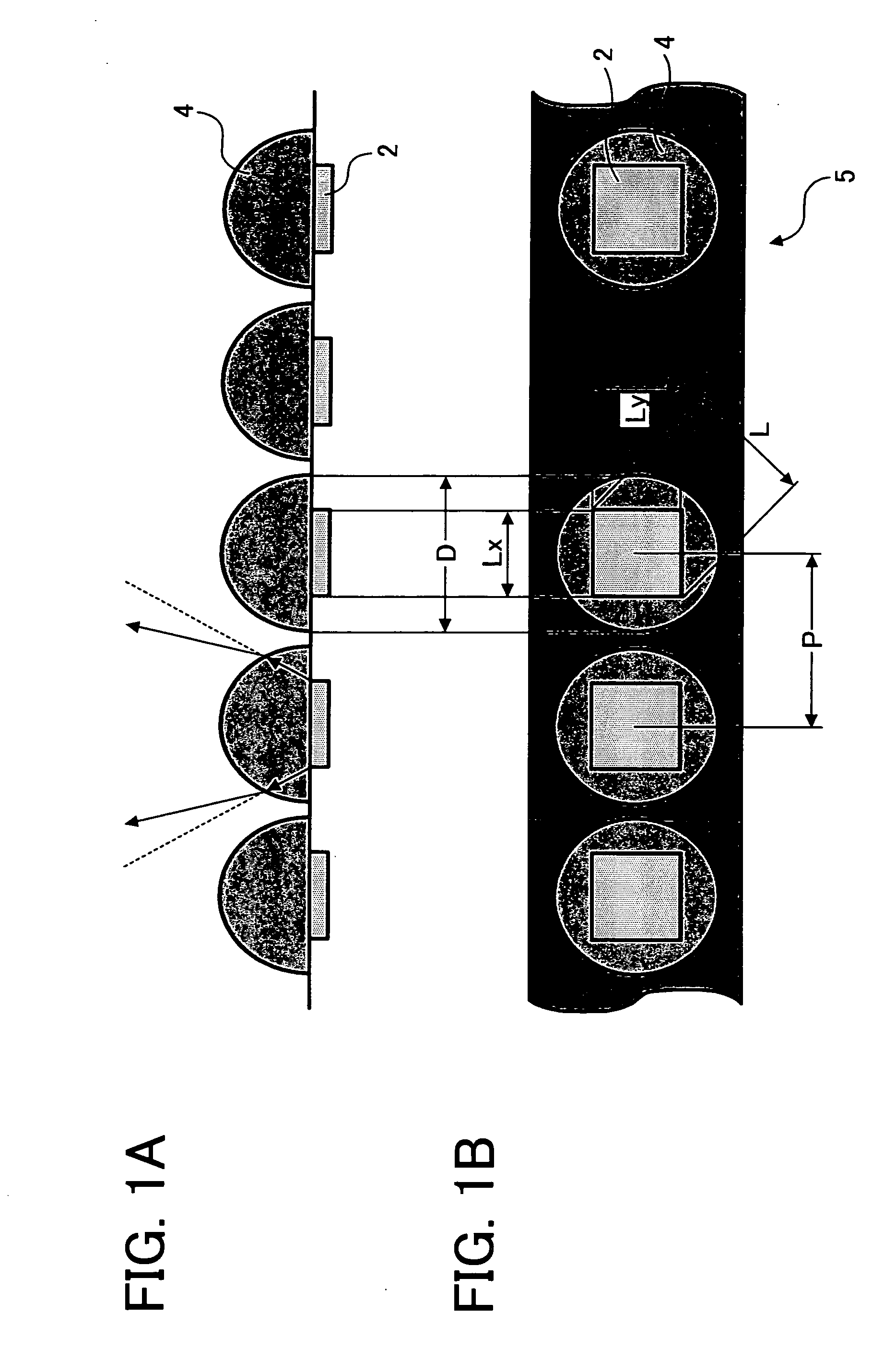

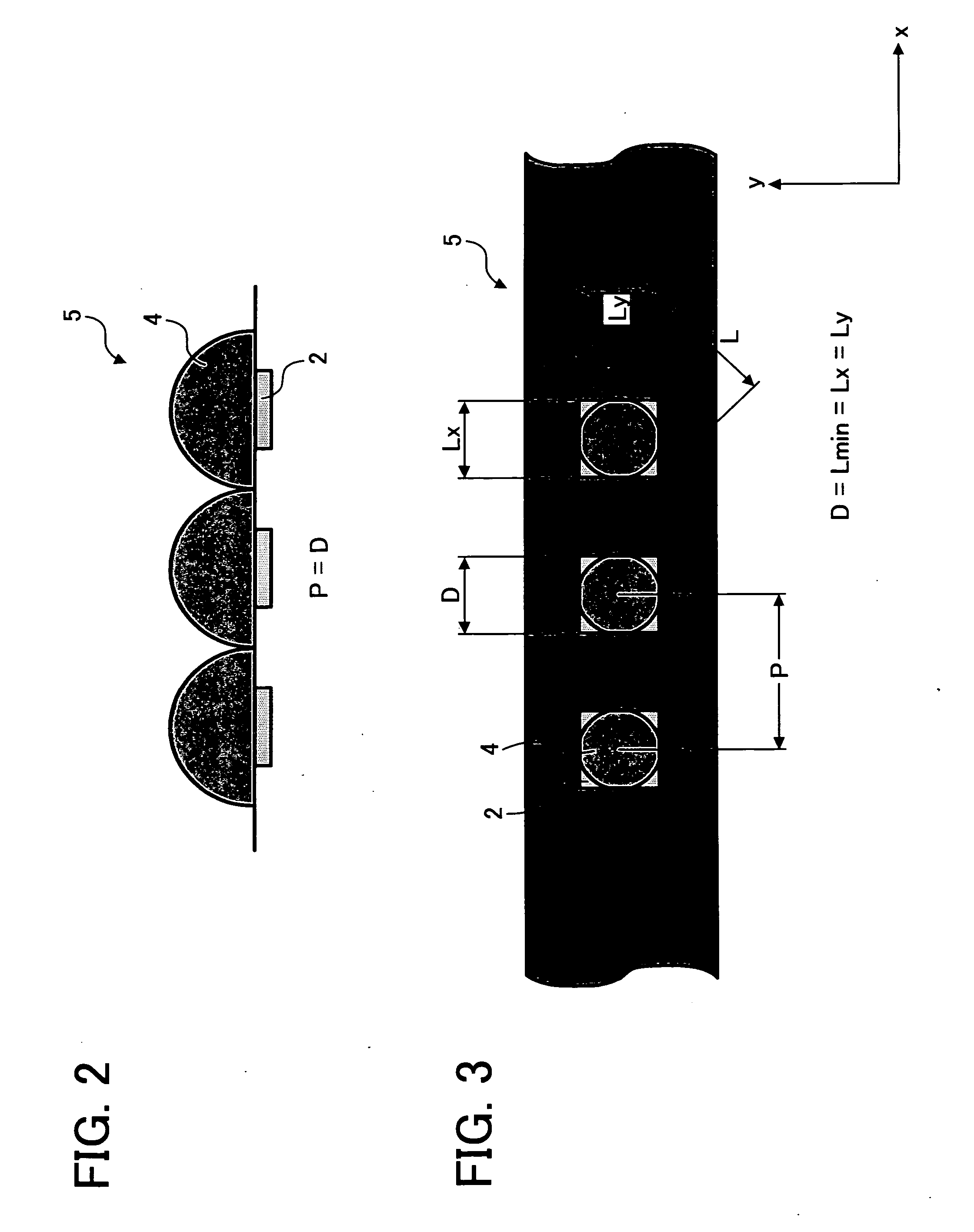

To achieve the foregoing and other objects, a light emitting array is provided including at least a plurality of light emitting elements, each of which is provided thereon with a microlens in one-to-one correspondence, in which the microlens is hemispherical in shape and separated from a microlens neighboring thereto.

In addition, the light emitting portion of the light emitting element is provided having the shape of rectangle and formed so as to satisfy the relational expression, Lmin≦D≦P, where Lmin is the length of the shorter side of the rectangle, P an alignment pitch of the light emitting elements, and D the diameter of the microlens.

The light emitting array disclosed herein may alternatively be formed with light emitting elements each having far-field emission angle characteristics of Lambert distribution.

The microlens included in the light emitting array may be formed of a transparent photoresist material on the light emitting elements formed in advance on a wafer.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com