Multi-layered preform and multi-layered bottle manufactured by using the same

a technology of multi-layered bottles and preforms, which is applied in the direction of synthetic resin layered products, transportation and packaging, and other domestic articles, can solve the problems of generating turbulence of resin flow, affecting the quality of molded products, and preforms showing poor appearance characteristics, etc., to enhance oxygen barrier properties, improve the quality of molded products, and improve the effect of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment 1

[0064] (Experiment 1)

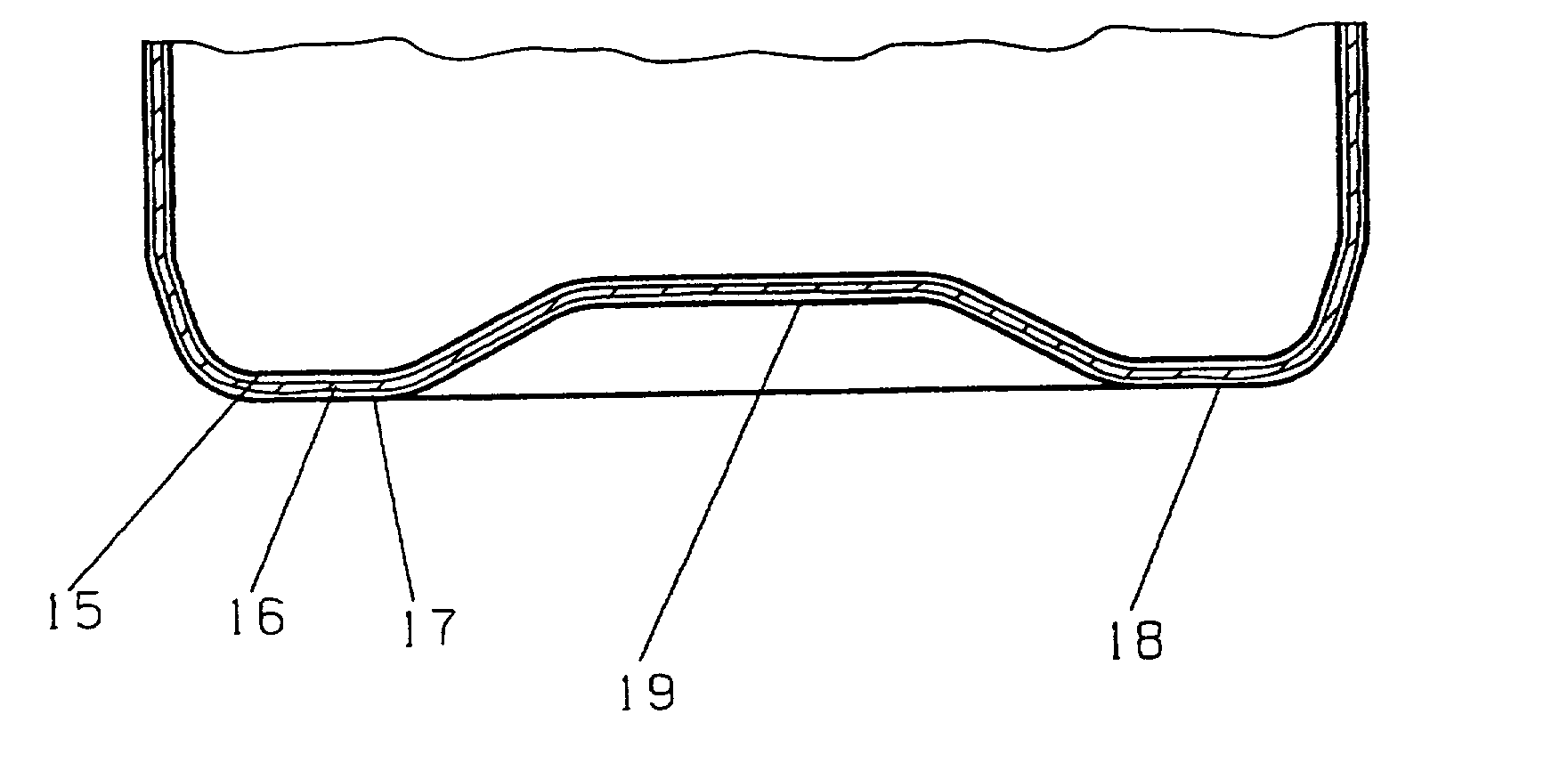

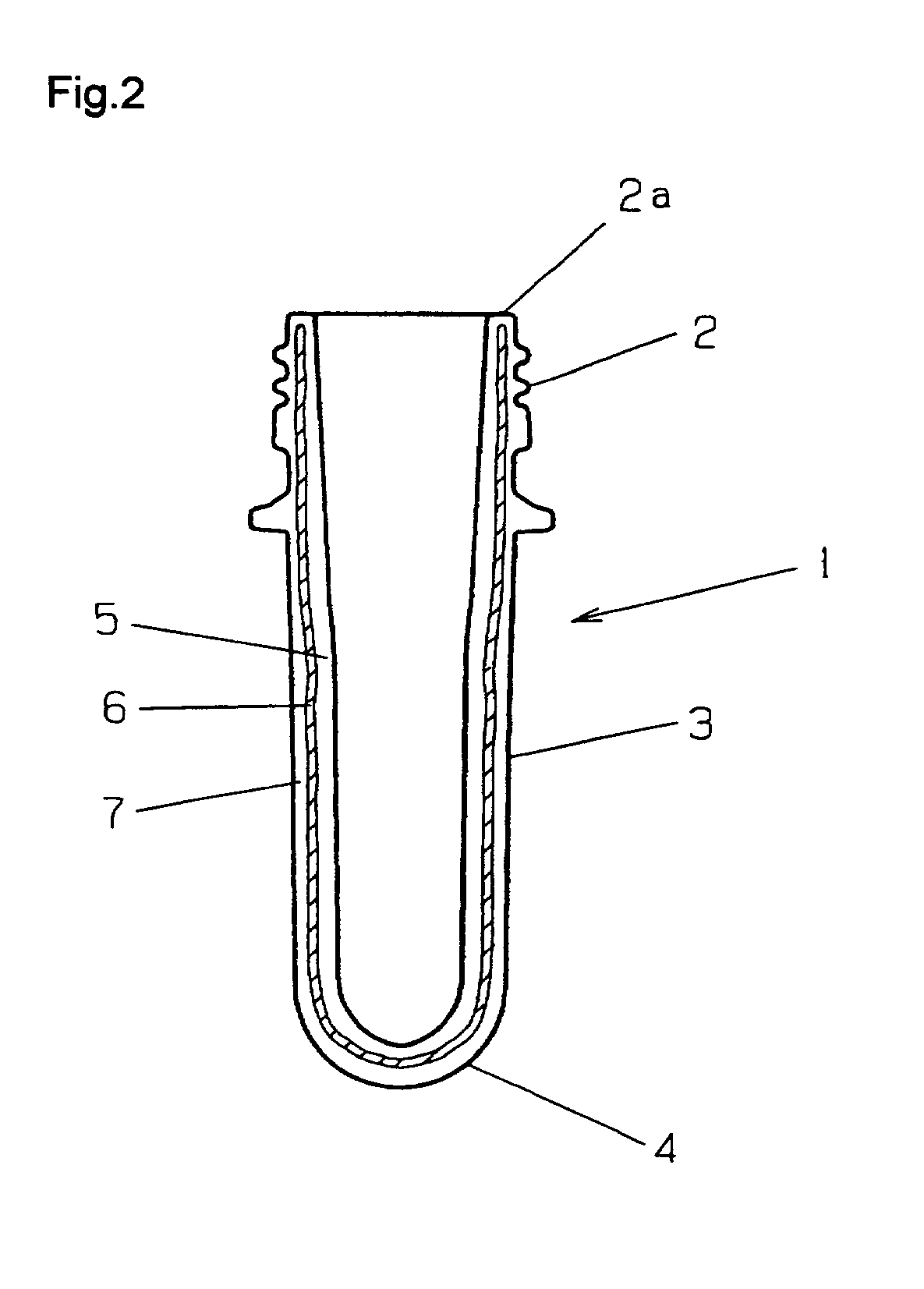

[0065] Polyethylene terephthalate (PET) having an intrinsic viscosity of 0.75 dl / g was supplied to an extruder for inner layer and outer layer and polymetaxylylene adipamido (MXD6 made by Mitsubishi Gasu Kagaku Kabushiki Kaisha) was supplied to an extruder for intermediate layer. Under the condition that the die temperature was set to 270.degree. C. and the resin pressure was set to 70 kgf / cm , these materials are extruded together such that the PET resin seals the MXD6 resin and they were cut into a given molten resin lump. This molten resin lump was set in the inside of a compression mold and the multi-layered compression forming was performed under the condition that the mold fastening pressure was set to 100 kgf / cm.sup.2 thus manufacturing a three-layered preform whose inner layer and outer layer were made of the PET and whose intermediate layer was made of the MXD6. A unit weight (METSUKE) of the preform was 25 g and the ratio of the intermediate layer was ...

experiment 2

[0066] (Experiment 2)

[0067] Except for that the resin which was produced by recycling the PET bottles collected from markets (PCR) was used as the intermediate layer, the multi-layered compression molding was performed under the same condition as the experiment 1 and a three-layered preform having the inner and outer layers made of the PET and the intermediate layer made of the recycled resin was manufactured. A unit weight (METSUKE) of the preform was 25 g and the ratio of the intermediate layer was 30 volume %.

experiment 3

[0068] (Experiment 3)

[0069] The three-layered preform of the first experiment was heated up to a temperature of 110.degree. C. which is not less than the glass transition point of the PET and this preform was set in the inside of a mold which is heated up to 60.degree. C. and a biaxial stretch blow molding was performed thus obtaining the three-layered bottle having a content of 500 cc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Cracking resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com