Position detection method and position detector, exposure method and exposure apparatus, and device and device manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

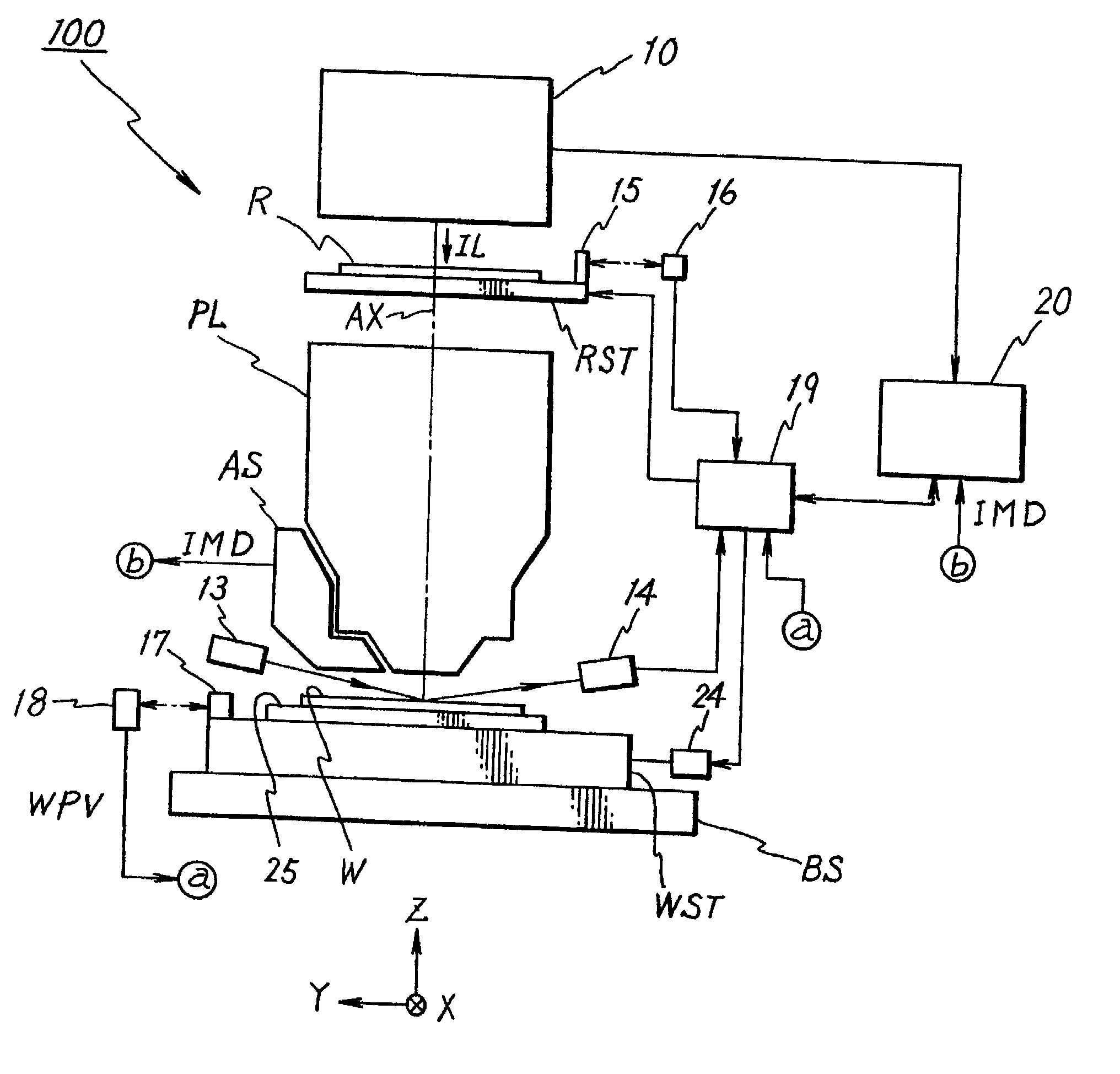

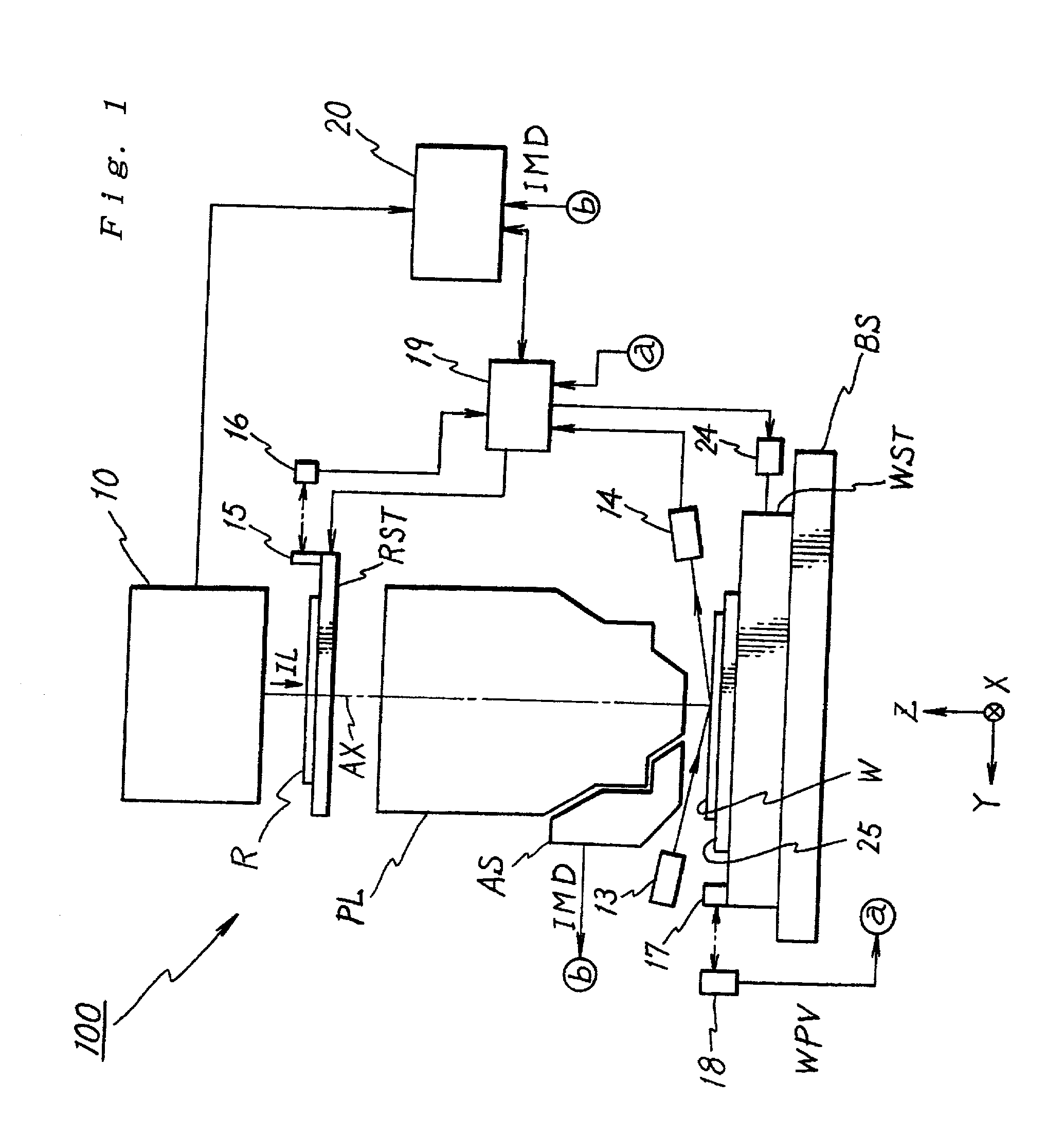

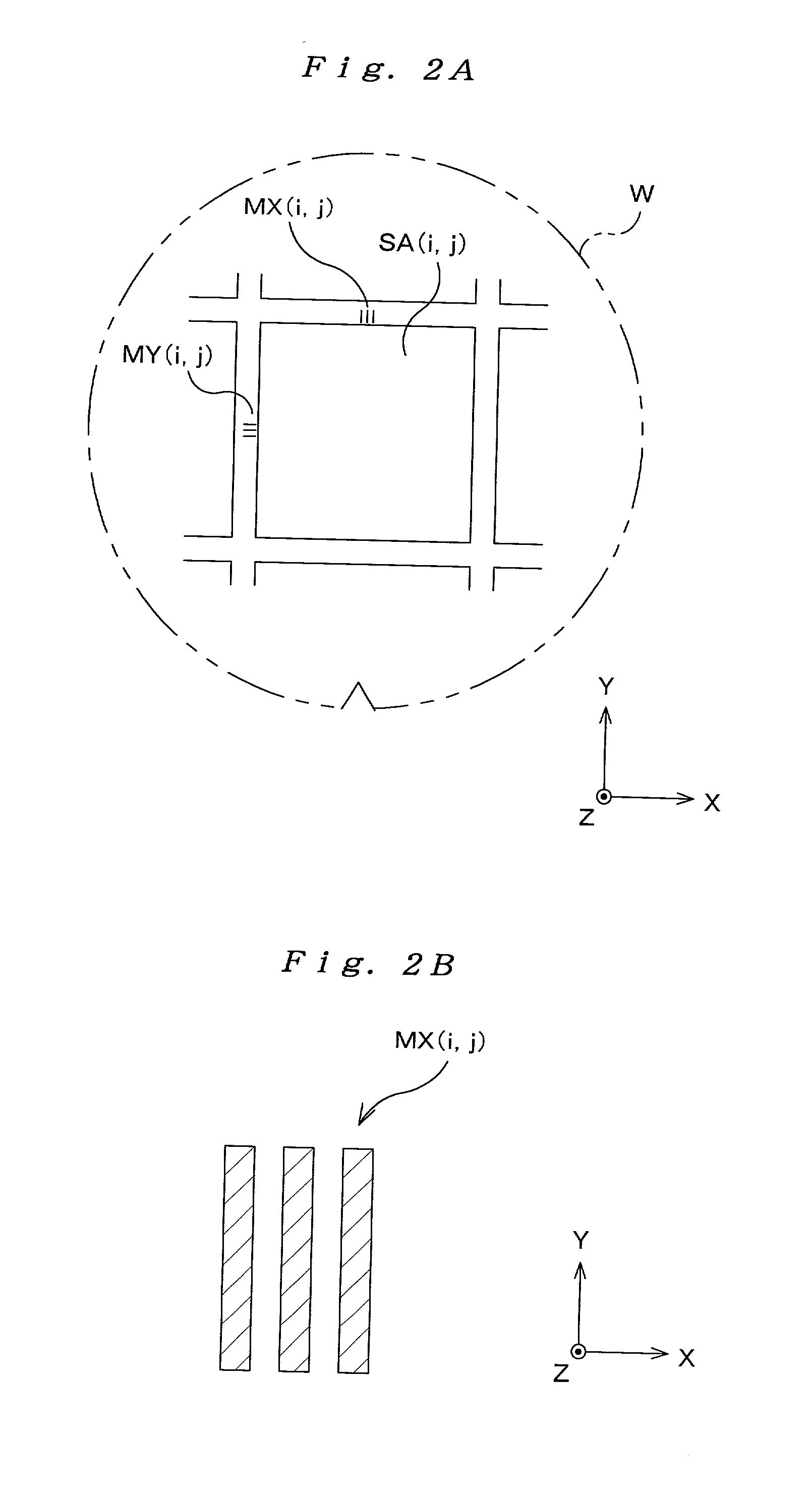

[0122] An embodiment of the present invention will be described hereinafter with reference to FIGS. 1 to 12.

[0123] FIG. 1 shows a schematic arrangement of an exposure apparatus 100 according to an embodiment of the present invention. This exposure apparatus 100 is a step-and-scan projection exposure apparatus. The exposure apparatus 100 comprises an illumination system 10, a reticle stage RST for holding a reticle R as a mask, a projection optical system PL, a wafer stage WST on which a wafer W as a substrate (object) is placed, an alignment microscope AS as an image pickup unit, a main control system 20 for systematically controlling the overall apparatus, and the like.

[0124] The illumination system 10 includes a light source, an illuminance uniforming optical system comprising a fly-eye lens as an optical integrator, a relay lens, a variable ND filter, a reticle blind, a dichroic mirror, and the like (none of them are shown). The arrangement of such illumination system is disclose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com