Thermal modulation system and method for locating a circuit defect

a technology of circuit defect and modulation system, which is applied in the field of thermal modulation system and method for locating circuit defects, can solve the problems of unstable structure of incipient defects, wide range of electrical resistance, and inadvertent short circuit connection, so as to improve fabrication quality and efficiently and accurately locate circuit defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

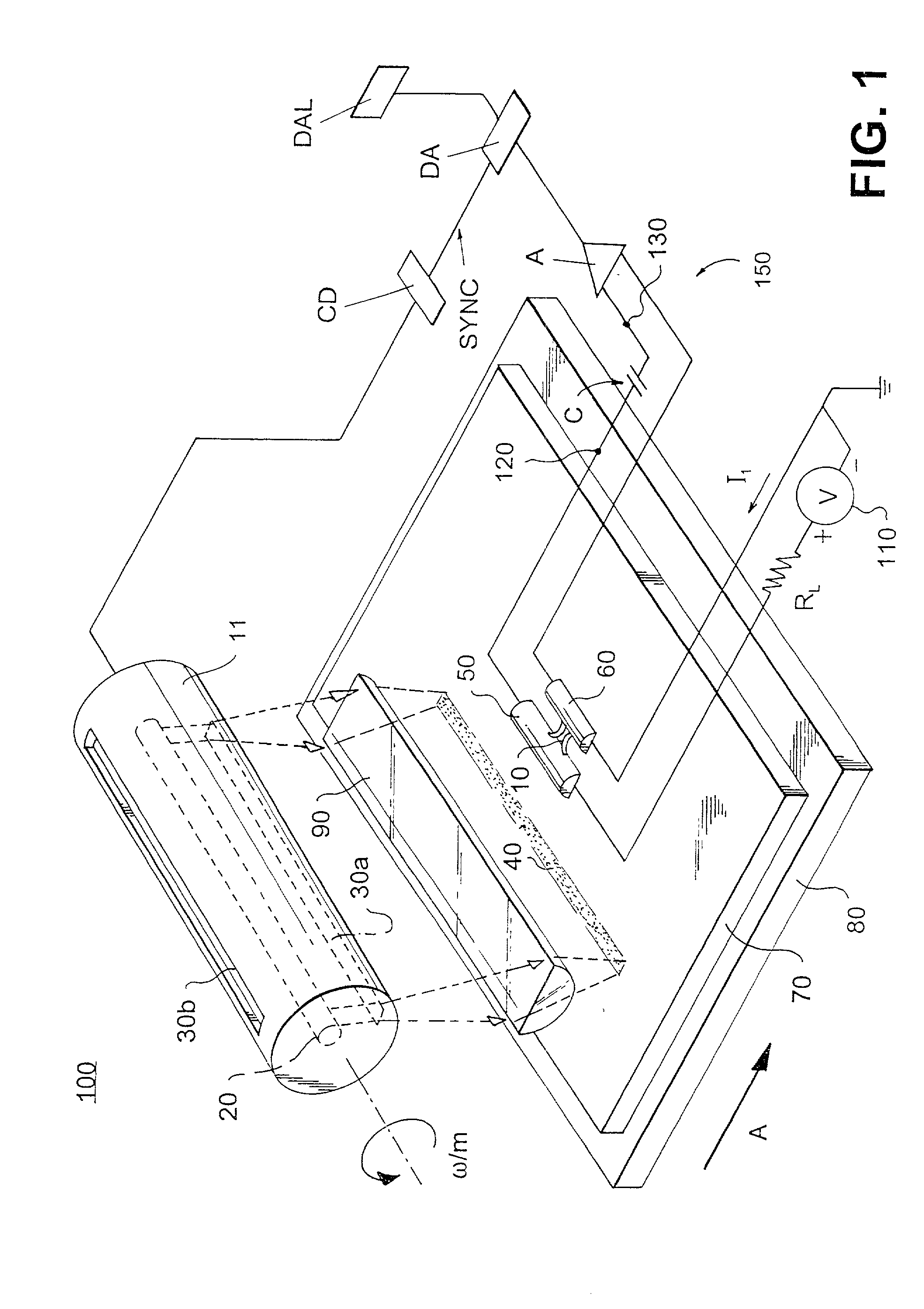

[0052] According to the invention as shown in FIG. 1, a narrow line segment 40 of incident radiant energy is applied over the entire length of a work piece at the same time and provides periodic heating over its entire length. When the thermal stimulus line segment overlaps with a circuit defect, somewhere in the workpiece, the circuit defect is periodically heated and the corresponding resistance change is measured and recorded. A long, narrow pattern of thermal stimulation reduces the time required to probe the entire workpiece, as will hereinafter be described in greater detail.

[0053] According to a first embodiment, FIG. 1 illustrates an apparatus 100 for thermally stimulating selected subsets of work piece 70 and measuring any corresponding change in circuit resistance. As shown in FIG. 1, a linear source of constant radiant energy 20, e.g., infrared radiation, is positioned within a hollow, slotted, rotating circular cylinder 11. This cylinder has "m" slot openings, for exampl...

second embodiment

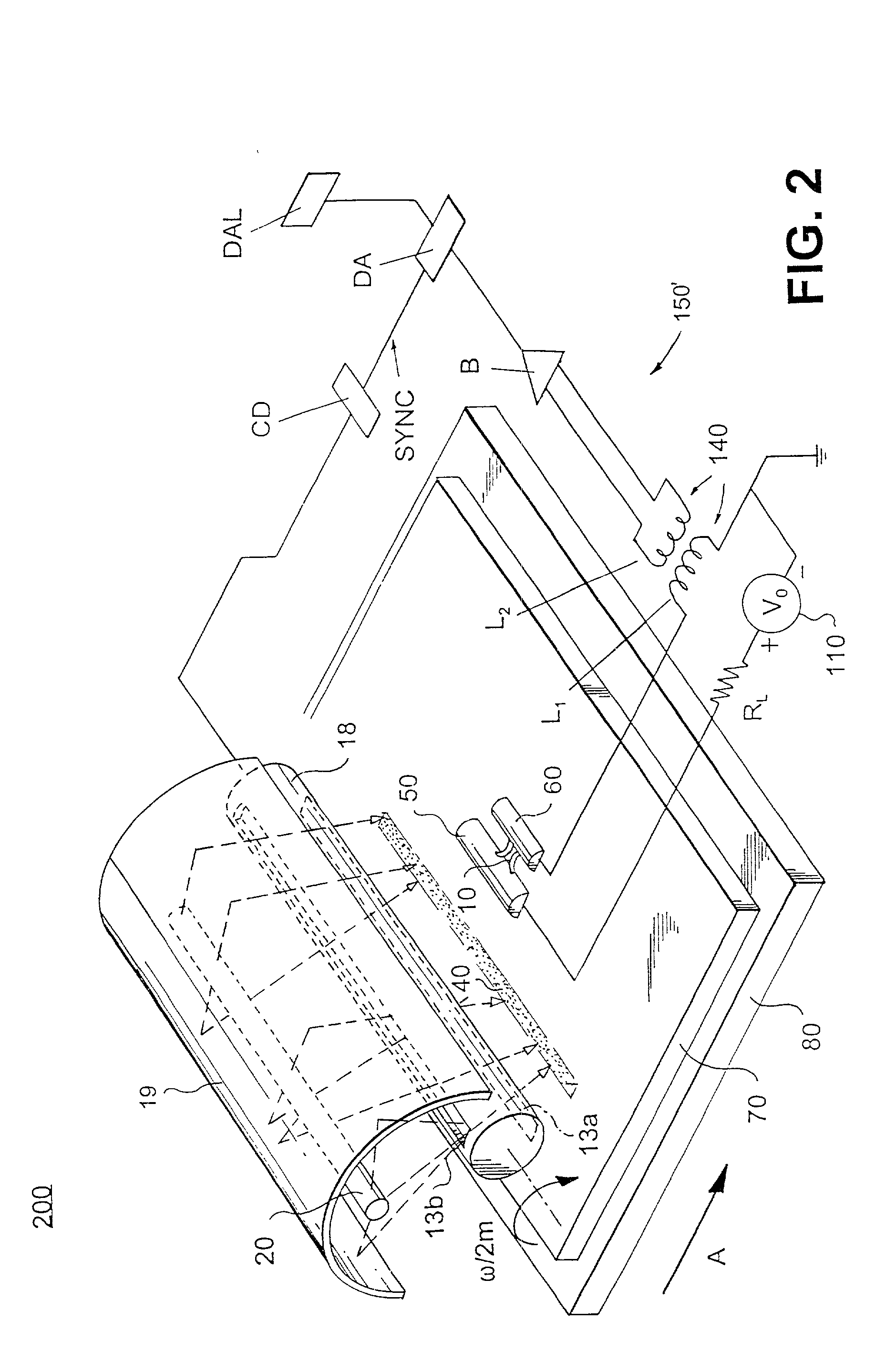

[0065] FIG. 2 illustrates an apparatus 200 according to a The apparatus of FIG. 2 operates like the apparatus 100 described with respect to FIG. 1. However, in FIG. 2, there is an elliptical trough reflector 19 which concentrates the stimulus into a narrow pattern 40. The radiation source is at one elliptical focus, and the workpiece is at the other elliptical focus. A hollow, slotted circular cylinder 18 has "m" diametrically opposed slot openings indicated as slot openings 13a, 13b, and is blocking elsewhere for radiation emanating from source 20. Preferably, the slotted circular cylinder 18 rotates at frequency .omega. / 2 m and modulates the narrow light segment 40 to turn "ON" and "OFF" at frequency .omega.. When thermal stimulus is applied to the resistive circuit defect 10, it produces a corresponding resistance change.

[0066] Procedures for locating the spatial position of resistive defect 10 are substantially as described in connection with the embodiment represented in FIG. ...

embodiment 500

[0079] FIGS. 7(a)-7(d) illustrates another embodiment 500 for expediently locating a circuit defect in two resolution stages. In FIG. 7(a), the thermal stimulus pattern 440 is a rectangle, e.g., 16 mm wide by 128 mm in height, and is scanned across workpiece at eight (8) positions, labeled X1.1 thru X1.8. Suppose the corresponding measurements indicate a defect only in subset X1.4. Then in FIG. 7(b), the thermal stimulus pattern 440' is a rectangle, e.g., 128 mm wide by 16 mm in height, which is additionally applied at eight (8) positions, labeled Y1.1 thru Y1.8. Suppose the corresponding measurements indicate the defect is in subset Y1.7. Thus, the workpiece 70 circuit has a single defect, i.e., located in an area defined by the intersection of X1.4 and Y1.7, which defect is in a refined search region which covers an area 450 of about 16 mm by 16 mm, such as shown in FIG. 7(c).

[0080] In the next stage of this embodiment, the thermal stimulus pattern is a smaller rectangle 460, e.g....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com