Visible-light response hybrid aerogel and preparation method and application thereof in waste gas processing

a technology of aerogel and visible light, applied in the field of nano composite materials, can solve the problems of large reduction dose, difficult control, poor water soluble and reactive gas, etc., and achieve the effects of low cost raw materials, simple preparation process, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0036]The preparation of carbon nitride nanosheets, the steps are as follows:

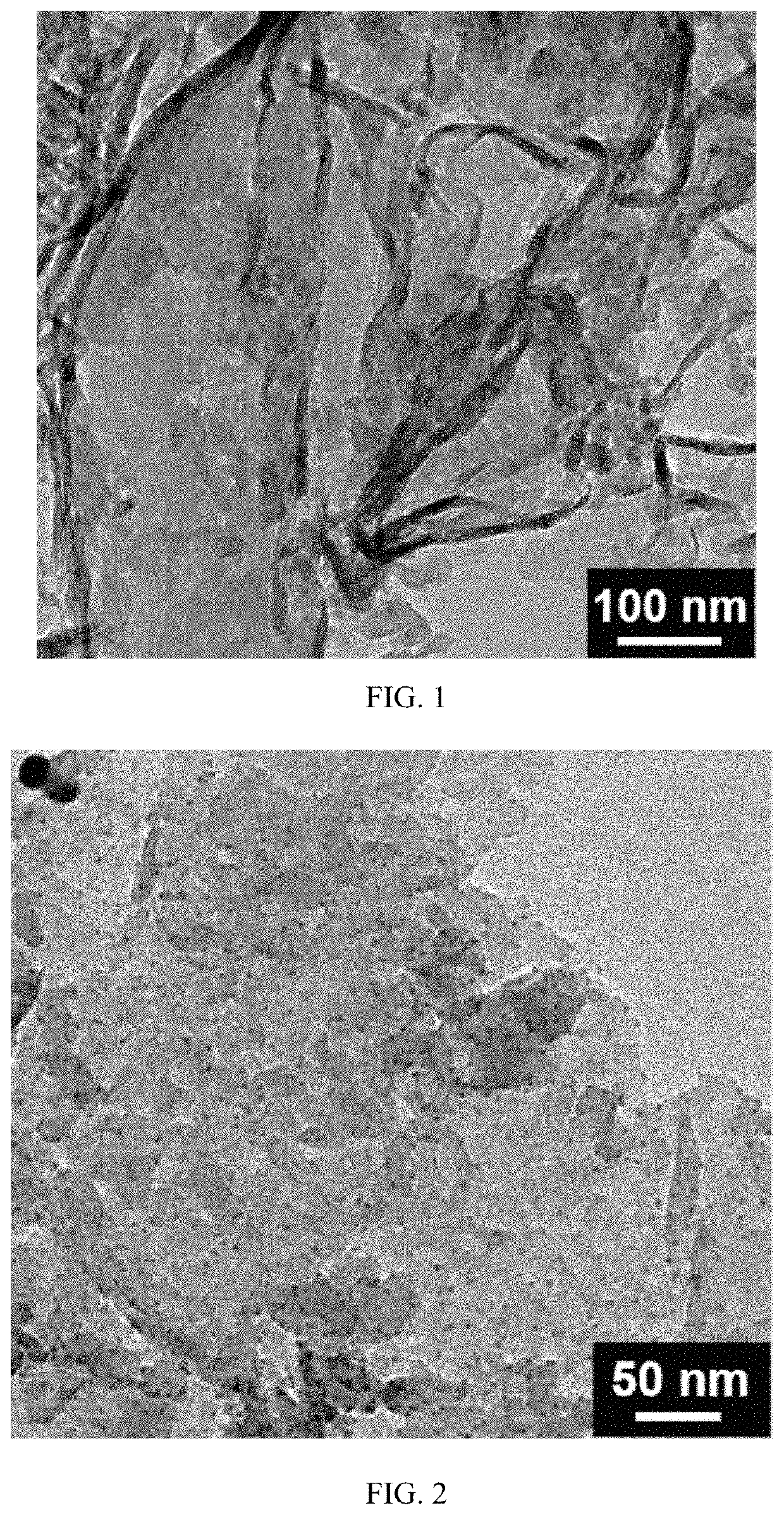

[0037]10 g of dicyandiamide is placed in a tube furnace and calcined under Ar gas atmosphere, and then heated to 550° C. for 4 h at a heating rate of 5° C. / min to obtain the bulk carbon nitride; the bulk carbon nitride is calcined in air, and heated to 550° C. for 2 h at a heating rate of 5° C. / min. The present invention uses calcination to obtain carbon nitride nanosheets with a large specific surface area. FIG. 1 is a Transmission electron microscopy image of the carbon nitride nanosheet.

embodiment 2

[0038]The preparation of silver metavanadate quantum dots / carbon nitride nanosheets is as follows:

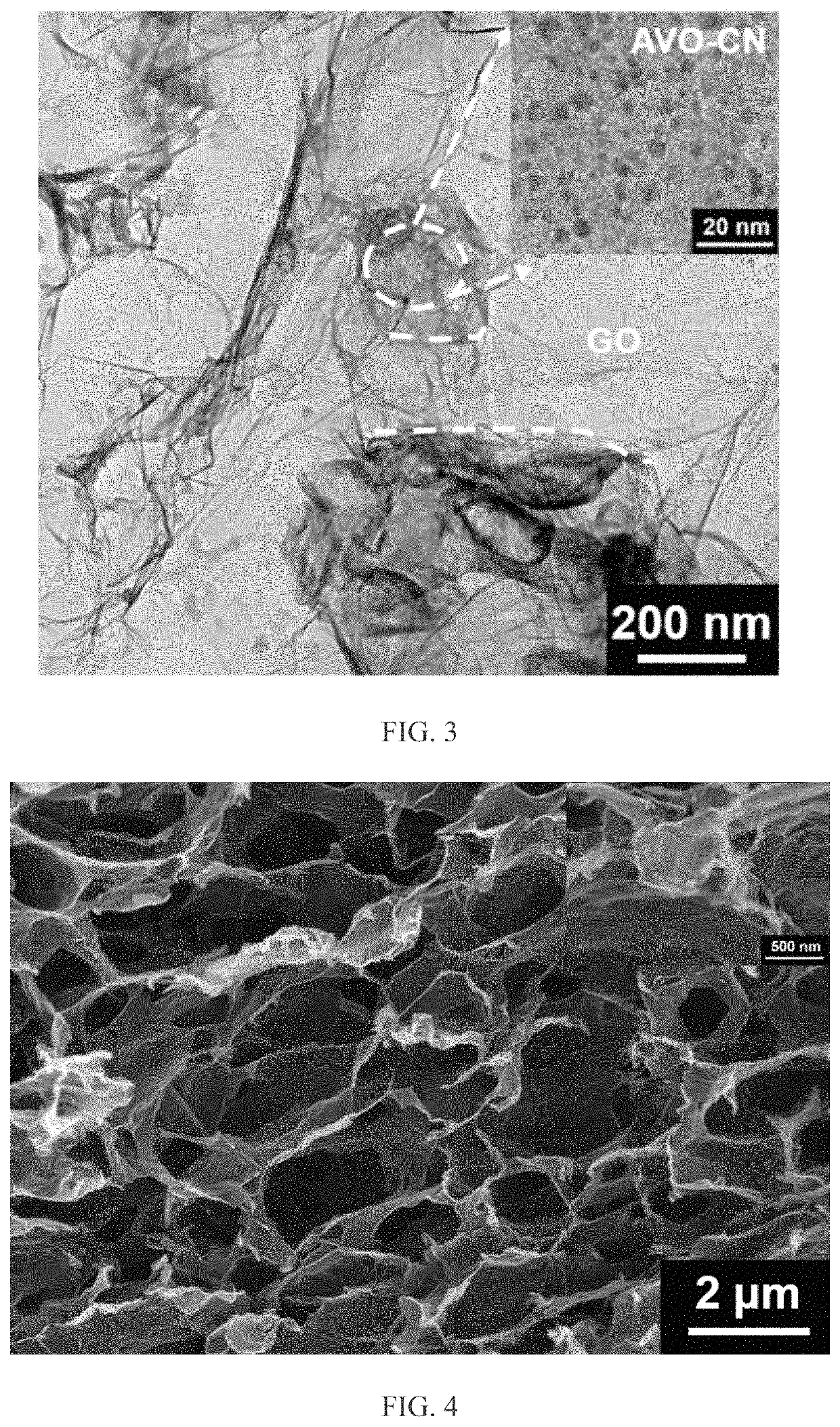

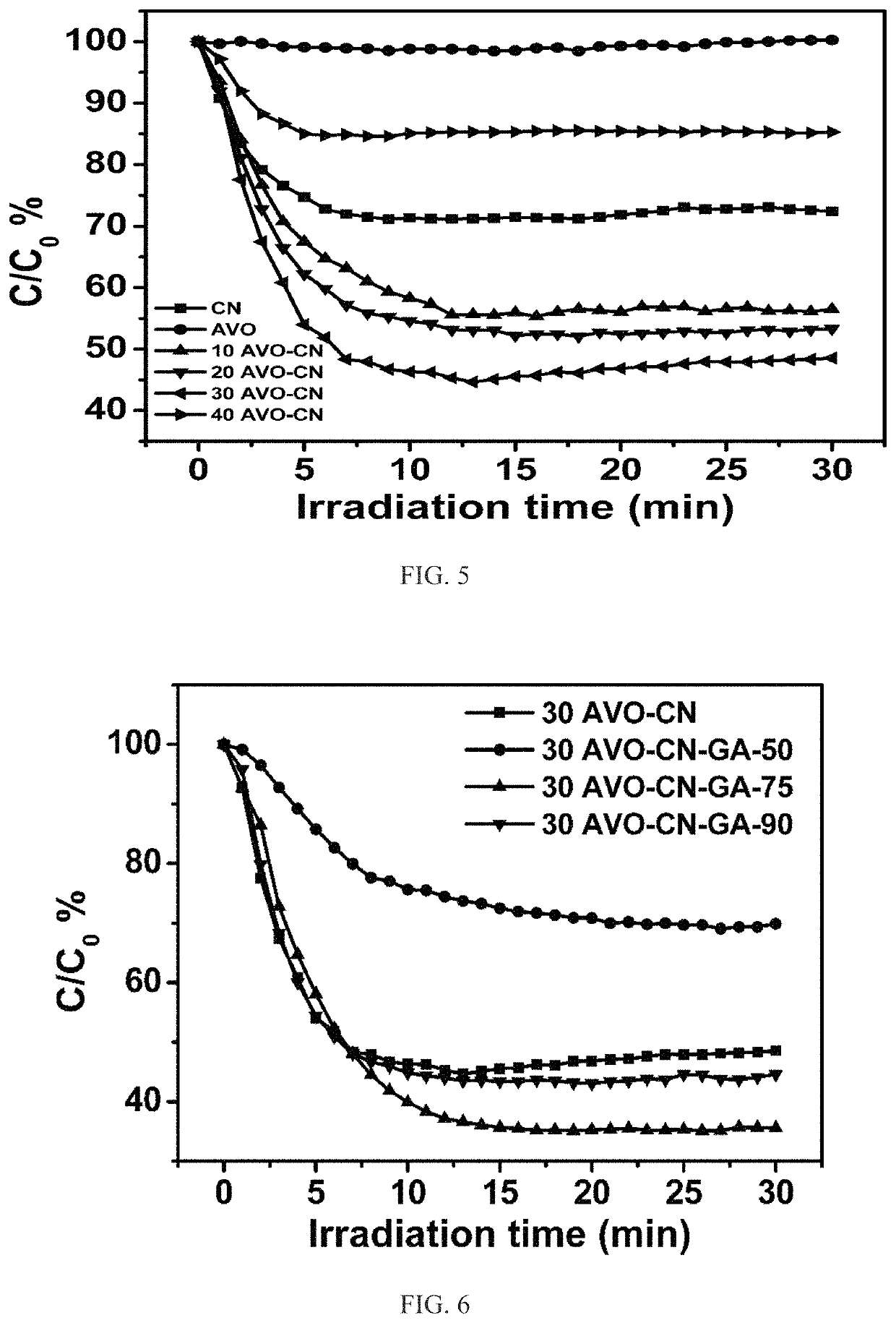

[0039]Silver nitrate (0.0170 g, 0.1 mmol) is dissolved in 20 ml of deionized water using a foil-wrapped beaker, and then carbon nitride nanosheets (0.1 g) is added to the solution and stirred for 30 minutes, the obtained suspension is then sonicated for 1 hour. 20 ml of ammonium metavanadate aqueous solution (0.0117 g, 0.1 mmol) is added to the suspension by a disposable syringe (20 ml) at a rate of 60 ml / h, and then the pH is adjusted to neutral and sonicated for 1 hour, and stirred in an oil bath for 8 hours. Finally, it is washed three times with deionized water and absolute ethanol. The product is placed in an oven at 80° C. for 8 h to prepare silver metavanadate quantum dots / carbon nitride nanosheets, which is recorded as AVO-CN. According to the quality of the added carbon nitride nanosheets, the composite materials with different loading quality of silver vanadate can be obtained...

embodiment 3

[0040]Preparation of silver metavanadate quantum dots / carbon nitride nanosheets / graphene hybrid aerogel is as follows:

[0041]15 mg of graphene oxide is added to a glass bottle (20 ml) and 4 ml of water is added thereto to uniformly disperse, then 45 mg of AVO30-CN is added to the graphene oxide dispersion. After ultrasonic mixing, 30 mg of L-ascorbic acid is added, and the mixture is placed in boiling water for half an hour to form a hydrogel and immediately frozen in a −40° C. refrigerator for 40 min. After natural melting, it is placed in a boiling water bath for 8 hours, and finally freeze-dried in a freeze dryer for two days to obtain a regular shape of light aerogel hybrid silver metavanadate quantum dots / carbon nitride nanosheets / graphene, which is denoted as AVO30-CN-GA-75 (AVO30-CN mass fraction is 75 wt %). According to the quality of the addition of graphene oxide, aerogel with different AVO30-CN mass loading can be prepared, denoted as AVO30-CN-GA-50, AVO30-CN-GA-75, AVO30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com