Process for purifying arsenic-containing mineral burned fume

A purification process and flue gas technology, applied in the field of flue gas purification and recovery of As2O3 flue gas purification, can solve the problems of high water consumption in the process, poor economic and technical indicators, and no recycling, etc., and achieves wide popularization and application value, Easy control and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

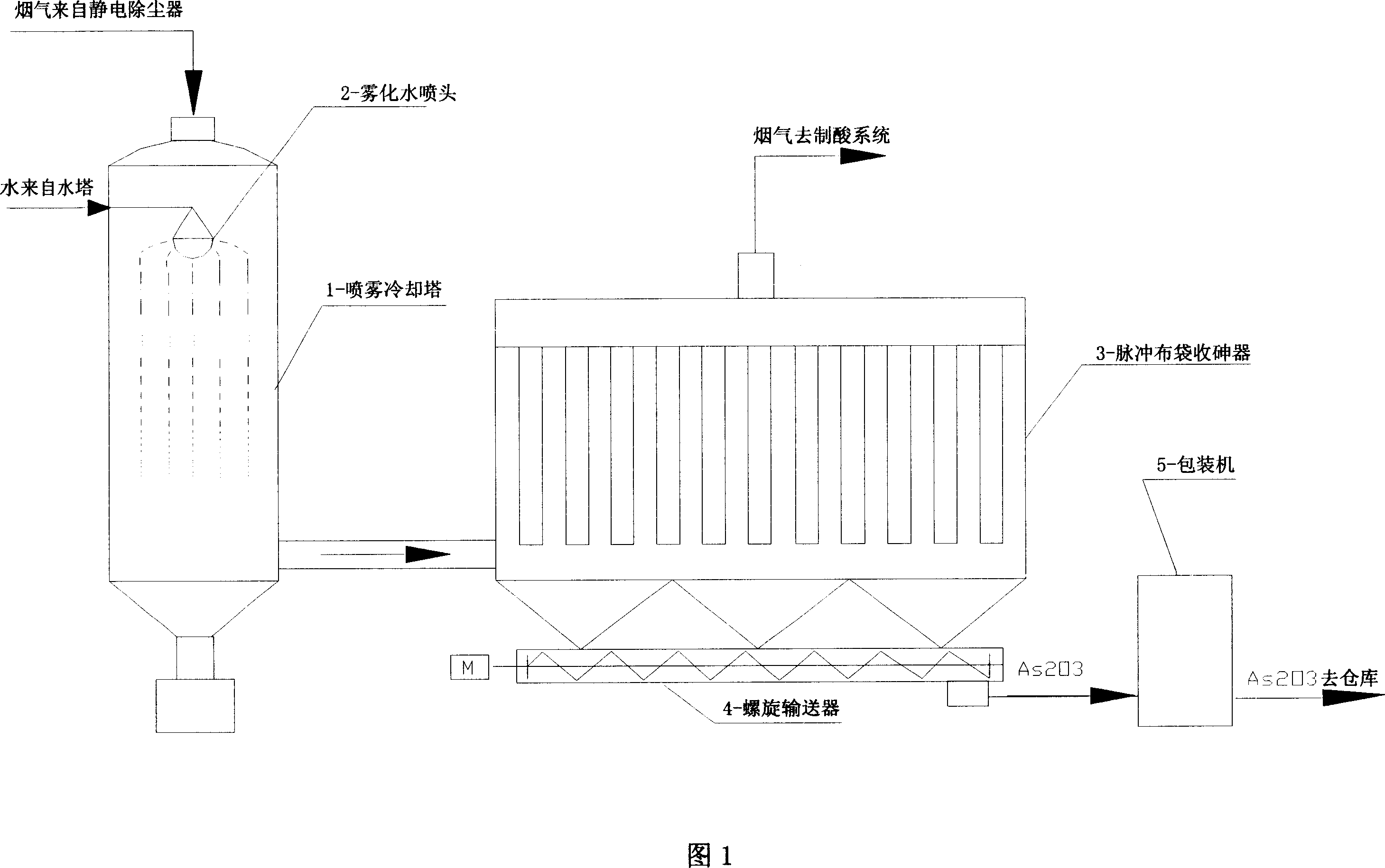

[0028] After the flue gas from the fluidized roasting furnace is collected and cooled by the furnace gas cooler-cyclone dust collector-electrostatic precipitator, etc., the temperature of the flue gas at the outlet of the electrostatic precipitator is controlled to drop to 280°C, and then it is introduced into the spray cooling tower 1, adjusted The water intake of the atomized water nozzle 2 makes the temperature of the flue gas at the outlet of the spray cooling tower 1 drop rapidly to 120°C. At this time, As 2 o 3 Crystallization becomes solid powder, enters pulse bag arsenic collector 3 to filter, As 2 o 3 The crystalline powder is sent to the packaging machine 5 for packaging through the screw conveyor 4 at the lower part of the pulse bag arsenic collector 3 .

[0029] Recovery of As 2 o 3 For the future flue gas, use conventional pickling flue gas purification methods such as internal spray venturi scrubber-packed tower scrubber-intercooler-electrostatic demister to ...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is that

[0032] After the flue gas from the fluidized roasting furnace is collected and cooled by the furnace gas cooler-cyclone dust collector-electrostatic precipitator, etc., the temperature of the flue gas at the outlet of the electrostatic precipitator is controlled to drop to 260°C, and then it is introduced into the spray cooling tower 1, adjusted The water intake of the atomized water nozzle 2 makes the temperature of the flue gas at the outlet of the spray cooling tower 1 drop rapidly to 100°C. At this time, As 2 o 3 Crystallization becomes solid powder, enters pulse bag arsenic collector 3 to filter, As 2 o 3 The crystalline powder is sent to the packaging machine 5 for packaging through the screw conveyor 4 at the lower part of the pulse bag arsenic collector 3 .

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is that

[0035] After the flue gas from the fluidized roaster is collected and cooled by the furnace gas cooler-cyclone dust collector-electrostatic precipitator, etc., the temperature of the flue gas at the outlet of the electrostatic precipitator is controlled to drop to 300°C, and then it is introduced into the spray cooling tower 1, adjusted The water intake of the atomized water nozzle 2 makes the temperature of the flue gas at the outlet of the spray cooling tower 1 drop rapidly to 140°C. At this time, As 2 o 3 Crystallization becomes solid powder, enters pulse bag arsenic collector 3 to filter, As 2 o 3 The crystalline powder is sent to the packaging machine 5 for packaging through the screw conveyor 4 at the lower part of the pulse bag arsenic collector 3 .

[0036] The technology of the present invention is applicable to the treatment of gold concentrates containing 1% to 10% of arsenic, preferably 4% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com