Method and device for synthesizing heat-conductive glue

A heat-conducting adhesive and mixing device technology, which is applied in the field of heat transfer, can solve the problems of long time required, difficulty in uniformly dispersing aggregates, low efficiency, etc., and achieve the effect of high-efficiency mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

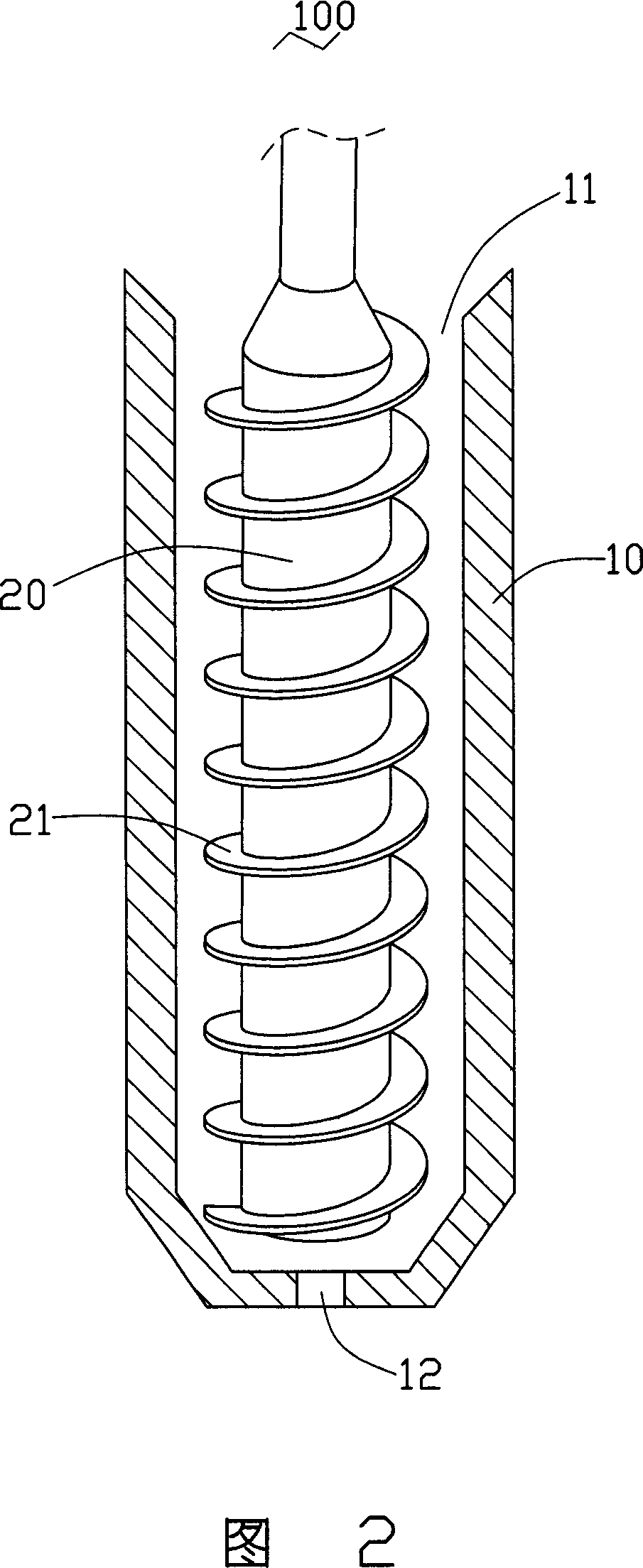

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

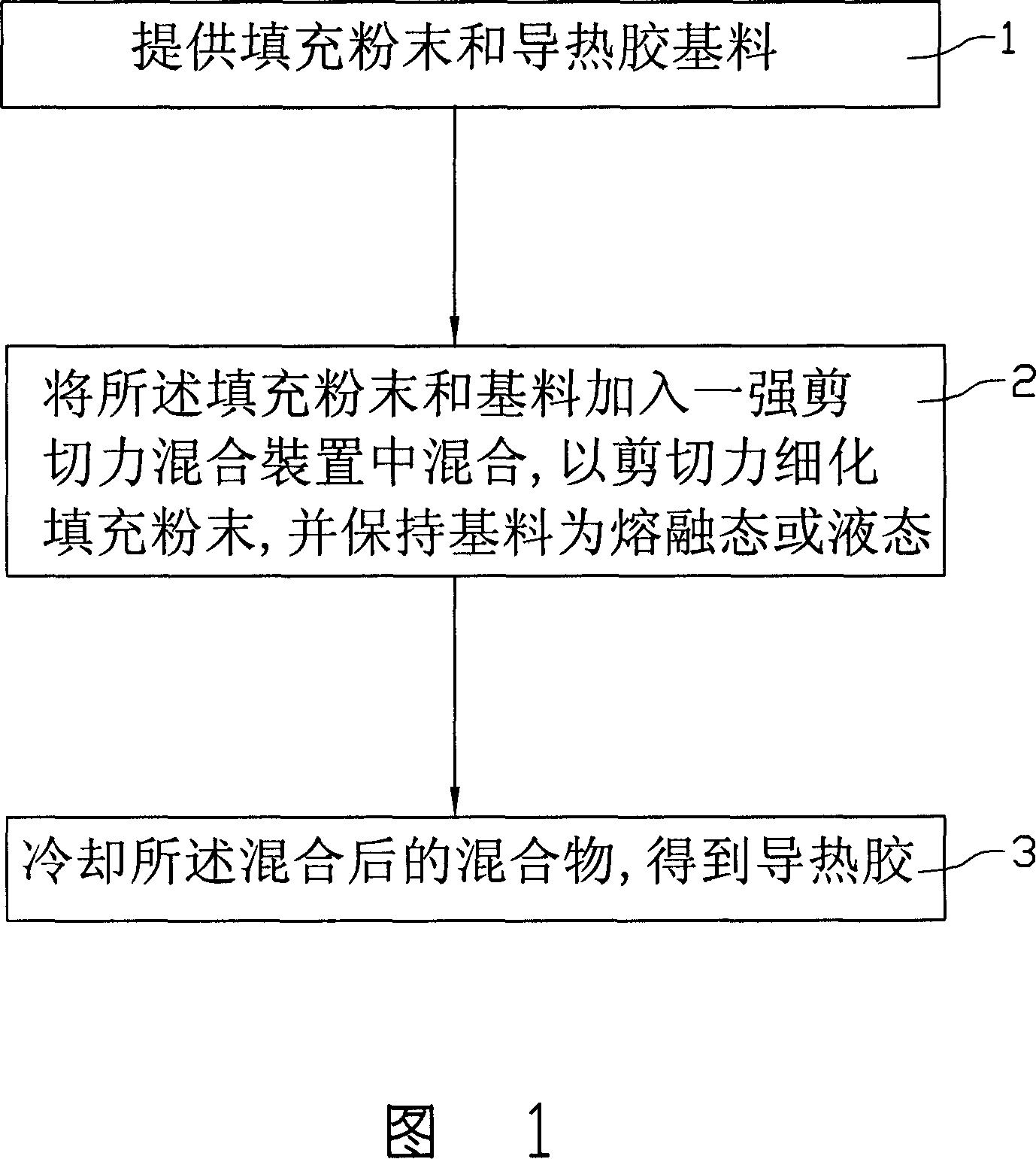

[0011] Please refer to Fig. 1, a method for synthesizing a thermally conductive adhesive provided by an embodiment of the present invention includes the following steps:

[0012] Step 1, provide filling powder and thermal conductive adhesive base. The filling powder is a thermally conductive substance, which can be one or more of silver, gold, copper, nickel, aluminum, aluminum oxide, zinc oxide, boron nitride, bauxite, aluminum nitride, graphite, carbon black A mix of species. The base material can be a liquid substance, a solid substance or a solid-liquid mixture at room temperature, wherein the liquid substance can be a mixture of one or more of silicone oil, polyethylene glycol, polyester, and the solid substance can be polyacetic acid One or more of ethylene, polyethylene, siloxane, polyvinyl chloride, amino epoxy resin, polyacrylate resin, polypropyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com