Steel and steel wire for high strength spring

A technology for heat treatment of steel and quality, applied in the field of spring steel, can solve problems such as insufficient sulfide control, and achieve high strength, high coilability, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] Tables 1 to 3 show the composition of the steel materials prepared for evaluation of various properties, and Tables 4 to 6 show the melting method and properties of the steel materials. A small amount of steel is smelted in a vacuum melting furnace (any one of 10kg, 150kg, 2t) or a 270t converter. The melting furnaces used for melting in each example are shown in the table. In the case of melting in a vacuum melting furnace, sufficient attention should be paid to mixing oxide generating elements from refractory materials or raw materials using magnesia crucibles, etc., and adjustments should be made so that the composition is the same as that of practical converter melting materials.

[0171] Of these slightly dissolved samples, 150 kg of material were rolled by welding with a dummy billet. In addition, after forging 10kg of charge into φ13, it is processed in the order of heat treatment (normalizing) and machining (φ10mm×400mm) to make thin straight rods. At this sta...

Embodiment 2

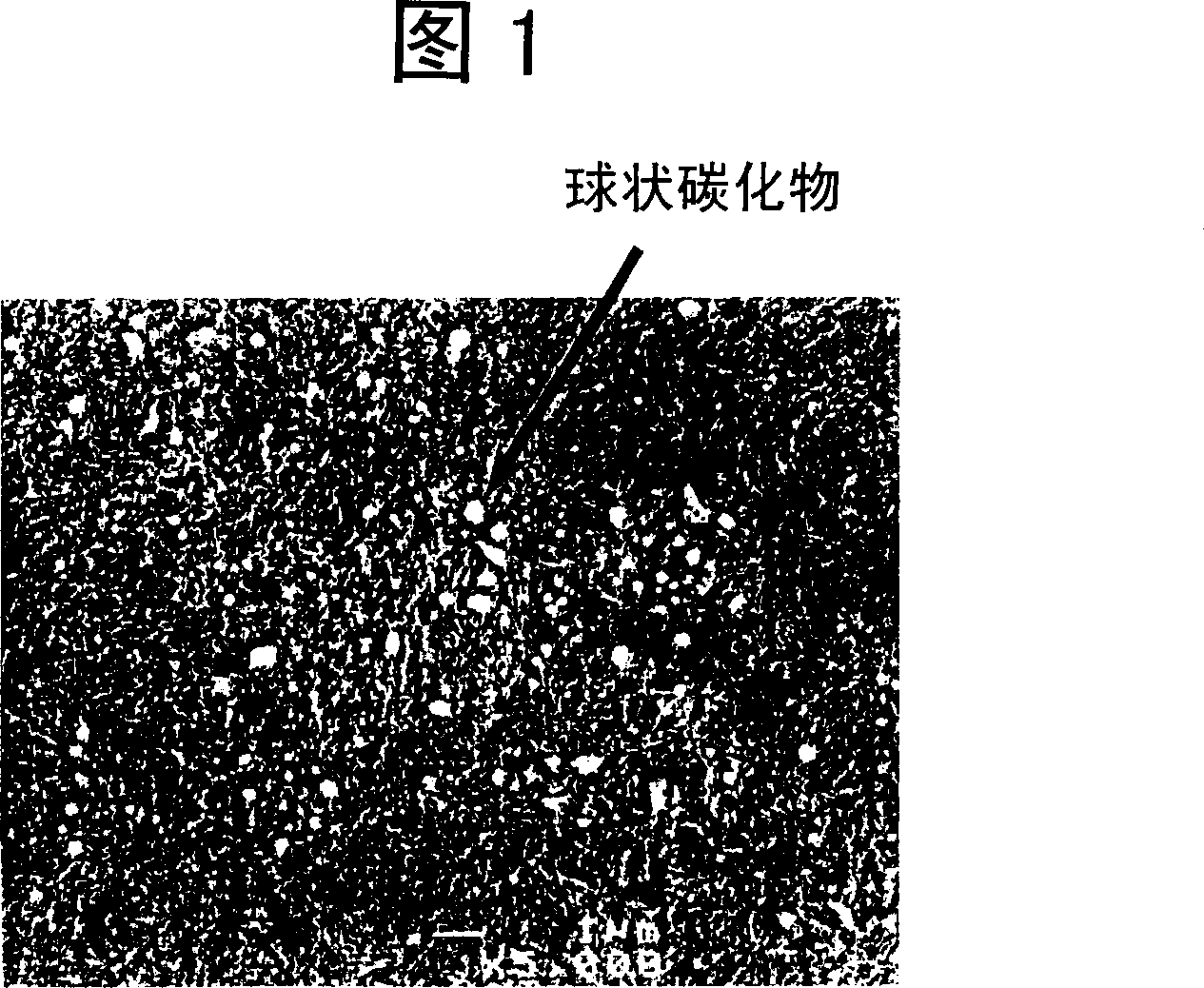

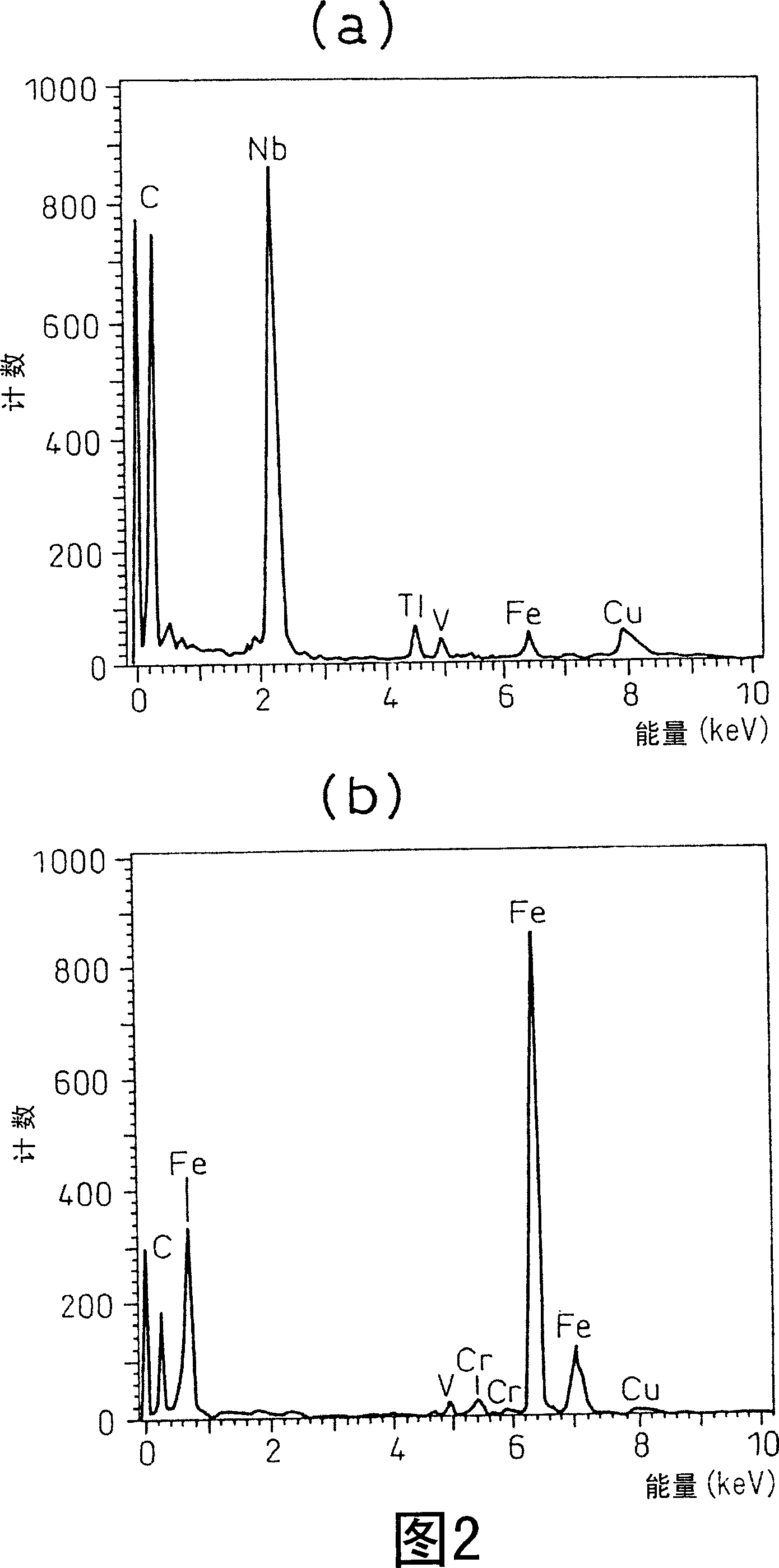

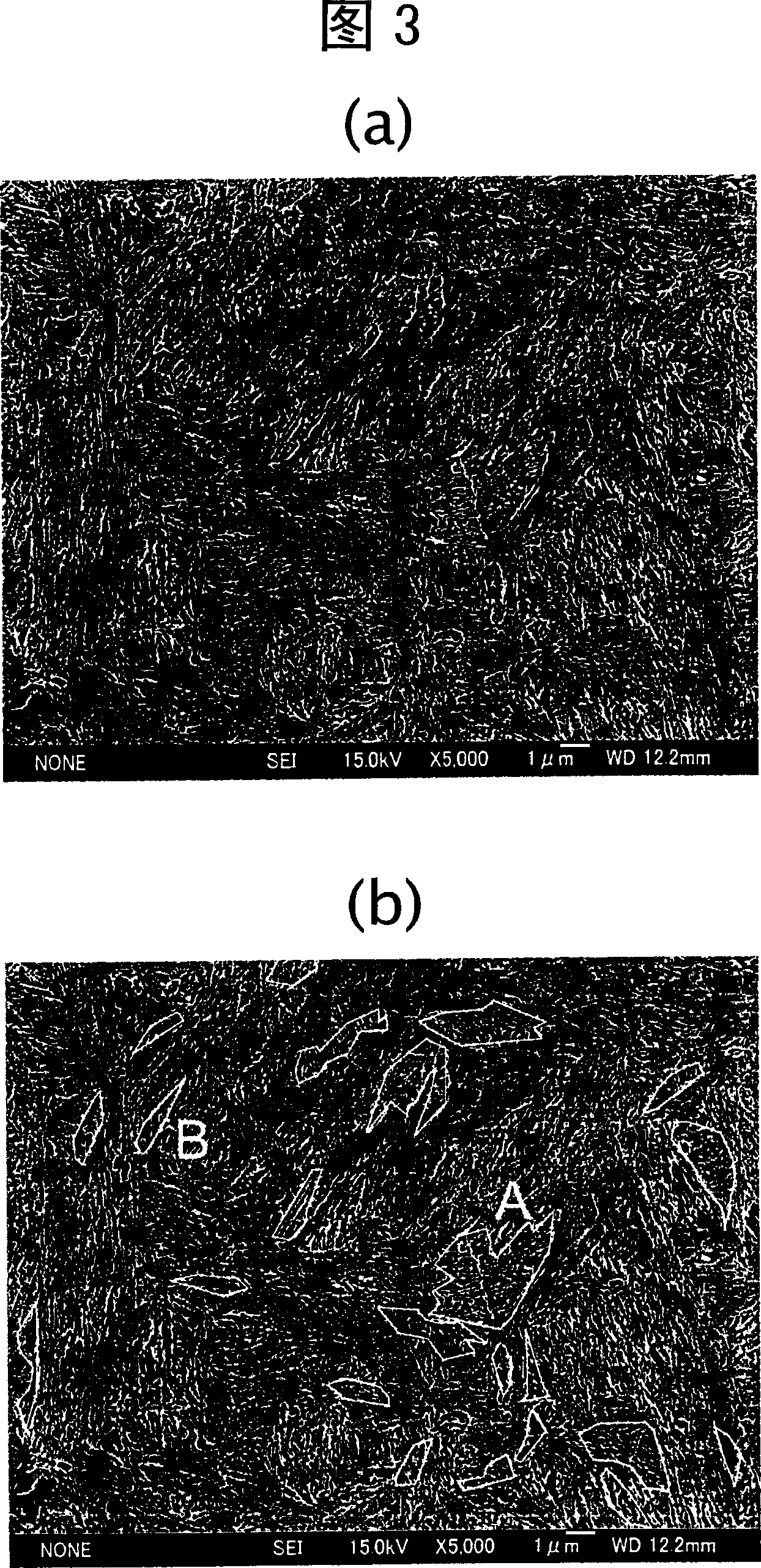

[0203] For the case treated with φ4mm, the chemical compositions of the present and comparative steels are shown in Tables 7 to 9, the area ratio of the rarefied region of the carburized carbides, the occupied area ratio of the alloy-based / carburized spherical carbides, and the equivalent weight Density of spherical carbides in carburized system with a circle diameter of 0.2 to 3 μm, density of spherical carbides in carburized system with an equivalent circle diameter of more than 3 μm, prior austenite grain size number, retained austenite content (mass %), tensile strength The strength, winding properties (tensile elongation), and average fatigue strength are shown in Tables 10 to 12.

[0204] Manufacturing method of sample (Wire-rod: wire rod)

[0205] In Invention Example 1 of the present invention, a material refined in a 250 t converter was produced into a billet by continuous casting. In addition, in other examples, after melting in a 2t-vacuum melting furnace, the bill...

Embodiment 70

[0230] In the case of Example 70, the tempering temperature was set to 600° C. to set a lower strength, so that the fatigue strength thereof was insufficient.

[0231] In Examples 71 to 73, the retained austenite reached a predetermined amount or more due to the fact that the cooling rate could not be ensured, even though the carbide thin region was small. Although the austenite grain size is small, the amount of retained austenite is intentionally increased by setting the cooling oil during quenching to 80°C or higher. As a result, the strength is insufficient, and fatigue properties cannot be ensured.

[0232] In the case of Examples 74 to 77, the heating temperature during quenching was set to 1000°C to suppress unsolution carbides, but the austenite grain size was increased, so sufficient ductility could not be ensured, and thus winding could not be ensured. sex.

[0233] Furthermore, in Examples 78 and 79, since the Si content was reduced, sufficient temper softening re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com