Electropolishing liquid and process for planarization of metal layer

A technology of electrolytic polishing and metal layer, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

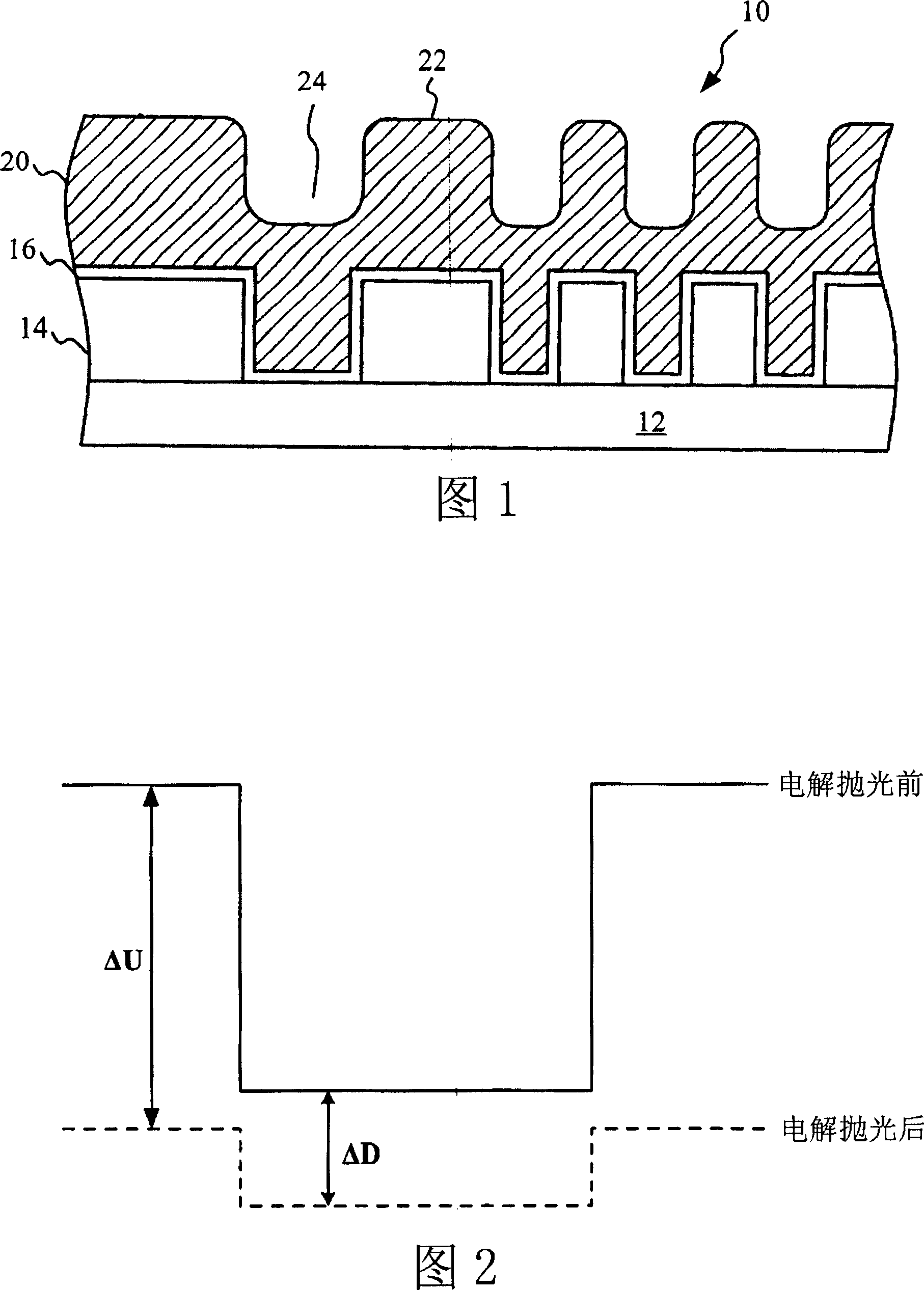

[0014] FIG. 1 is a cross-sectional view of a wafer 10 . As shown in FIG. 1 , the wafer 10 includes a substrate 12 , a dielectric layer 14 , a barrier layer 16 and a metal layer 20 . The metal layer 20 can be a copper layer and has a protrusion 22 and a recess 24 . The present invention uses an electrolytic polishing solution to planarize the metal layer 20 . The electrolytic polishing solution includes an alcohol-based additive and an acid solution. Preferably, the alcohol-containing additive can be glycerin, methanol or ethanol, and the acid solution contains phosphoric acid and an organic acid additive. Furthermore, the acid solution may also contain sulfuric acid. The preparation method of the electrolytic polishing liquid is to mix a predetermined ratio of phosphoric acid and an alcohol-based additive, and then add the organic acid additive. The organic acid additive can be acetic acid or citric acid, wherein the concentration of acetic acid is between 10000-12000 ppm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com