Bipolar semiconductor device and process for producing the same

A manufacturing method, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problems of increased component loss, increased power conversion device loss, and reduced reliability, and achieve the effect of reducing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

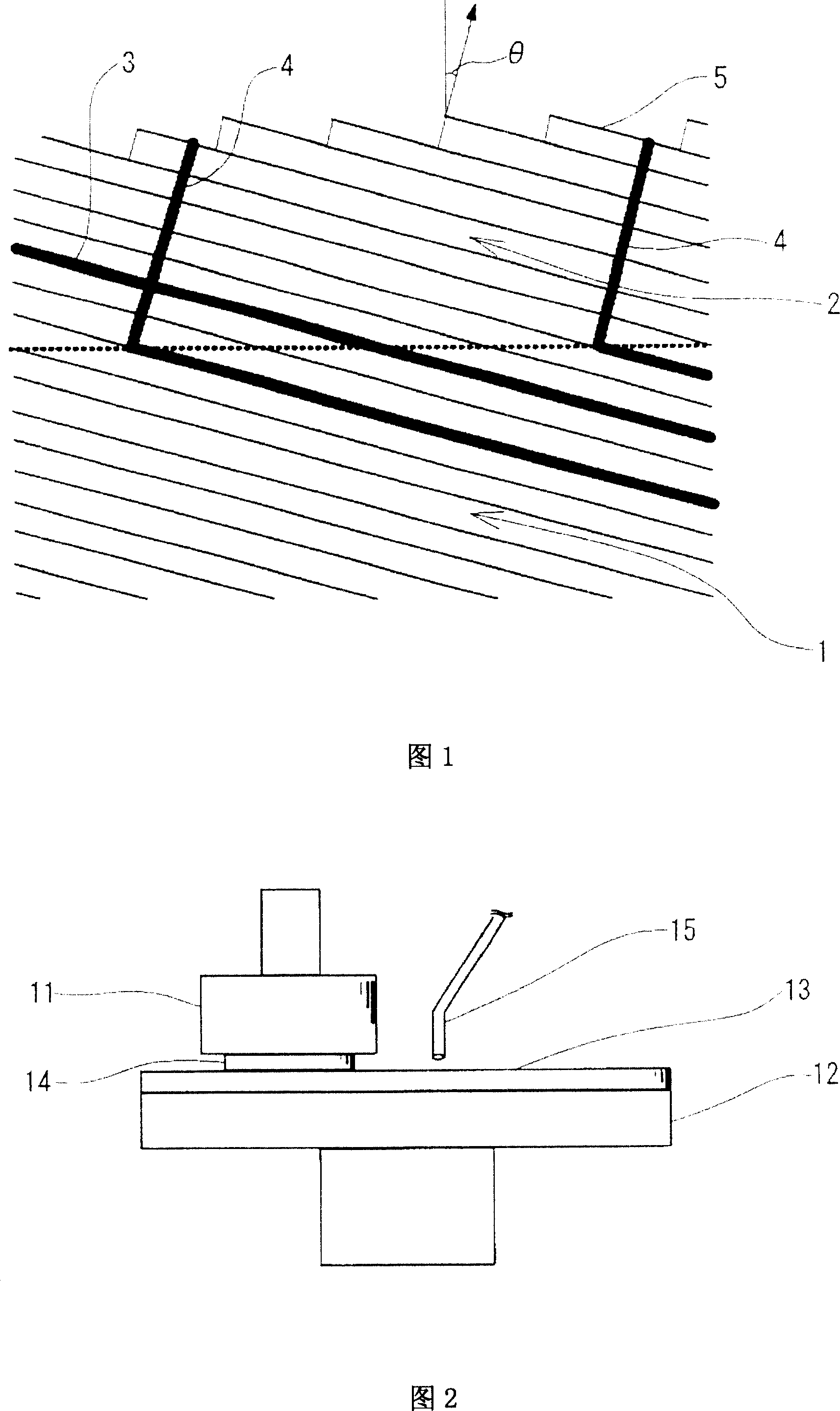

[0097] Using a vertical thermal furnace, the crystal block grown by the modified Rayleigh method is cut into thin slices according to the oblique orientation [11-20] and the deviation angle is 8°, and the mirror-like n-type 4H- For the SiC (0001) substrate, hydrogen gas was supplied to the substrate at a flow rate of 10 L / min, and etching treatment was performed at a temperature of 1400° C. and a pressure of 30 Torr for 40 minutes. The surface roughness Rms of the treated substrate surface was measured with an atomic force microscope SPI3800N manufactured by Seiko Instruments Co., Ltd. and found to be 0.25 nm (area of 10 μm×10 μm).

[0098] Second, epitaxially grow silicon carbide on the surface of the treated substrate by CVD. While supplying propane (8cc / min), silane (30cc / min), and hydrogen (10L / min), at a temperature of 1545°C and a pressure of 42Torr, a stepwise slip growth was performed for 4 hours to form a film with a thickness of 60μm. epitaxial film.

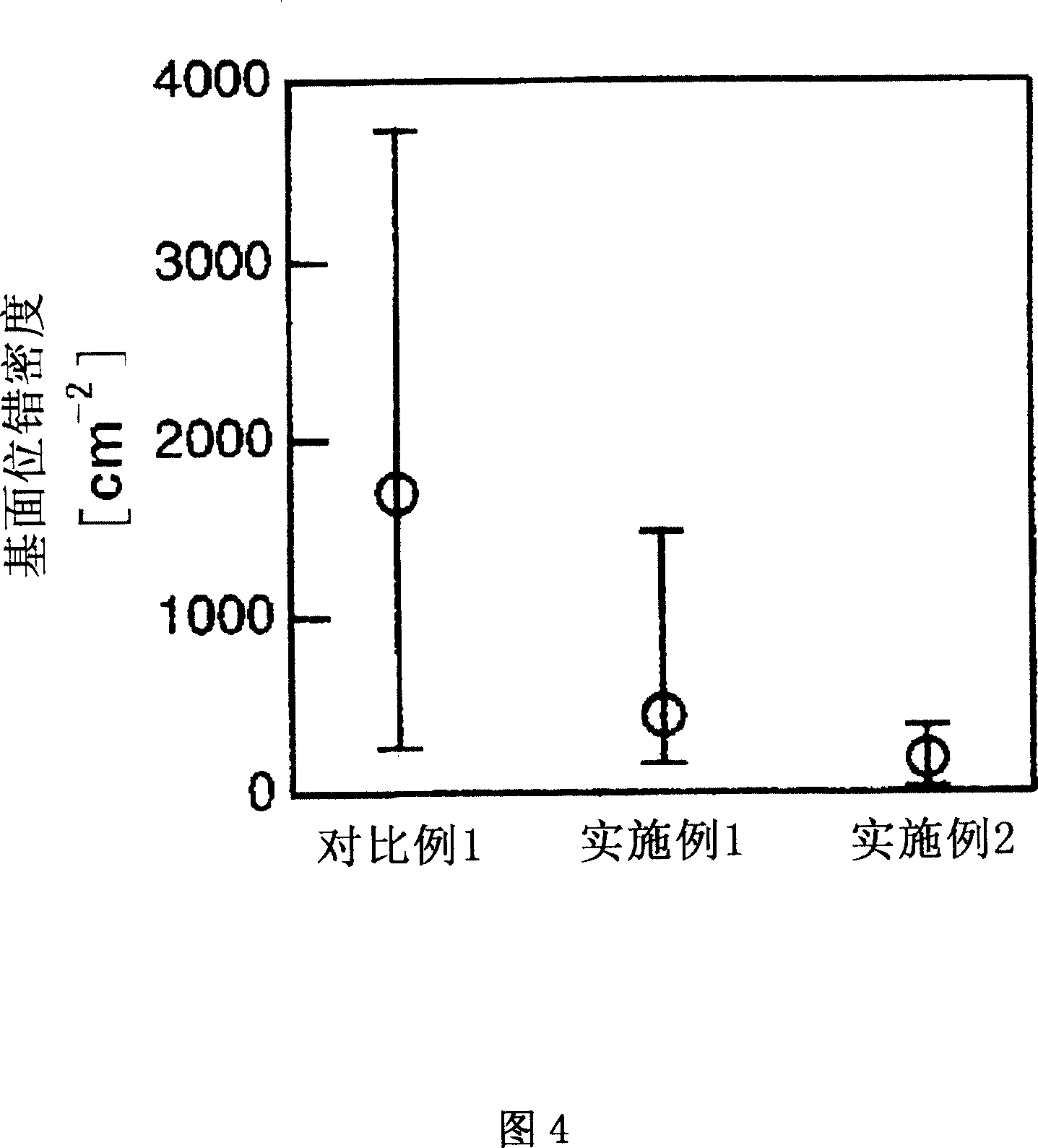

[0099] For...

Embodiment 2

[0101] A silicon carbide single crystal substrate with an epitaxial film was obtained in the same manner as in Example 1 except that the surface of the substrate was treated by chemical mechanical polishing before the hydrogen etching treatment. The surface roughness Rms of the treated substrate surface was measured in the same manner as in Example 1 and found to be 0.20 nm (area of 10 μm×10 μm).

[0102] For the obtained silicon carbide single crystal substrate with epitaxial film, the results of measuring the basal plane dislocation density in the epitaxial film by using molten KOH corrosion and X-ray topography, the average value is 60cm -2 .

Embodiment 3

[0104] A mirror-like n-type 4H-SiC (000-1) obtained by cutting the crystal block grown by the modified Rayleigh method into thin slices with an oblique orientation [11-20] and an off-angle of 8°, and mechanically grinding the surface with abrasive grains The substrate was subjected to the same chemical mechanical polishing treatment and hydrogen etching treatment as in Example 2 to grow an epitaxial film. In the same manner as in Example 1, the surface roughness Rms of the treated substrate surface was measured to be 0.20 nm (area of 10 μm×10 μm).

[0105] For the obtained silicon carbide single crystal substrate with epitaxial film, the results of measuring the basal plane dislocation density in the epitaxial film by using molten KOH corrosion and X-ray topography, the average value is 20 cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com