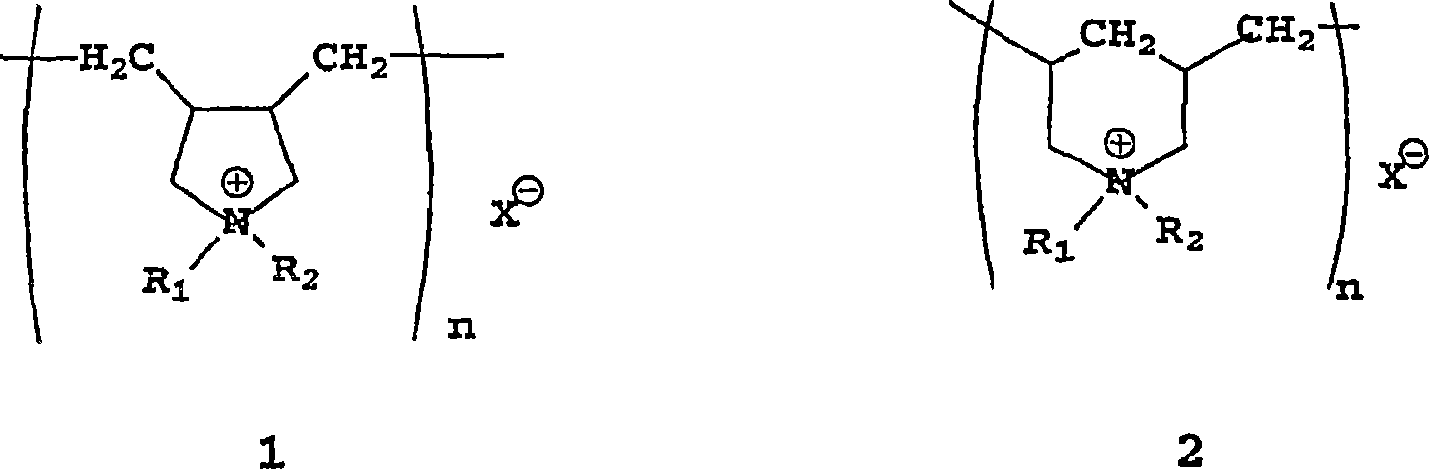

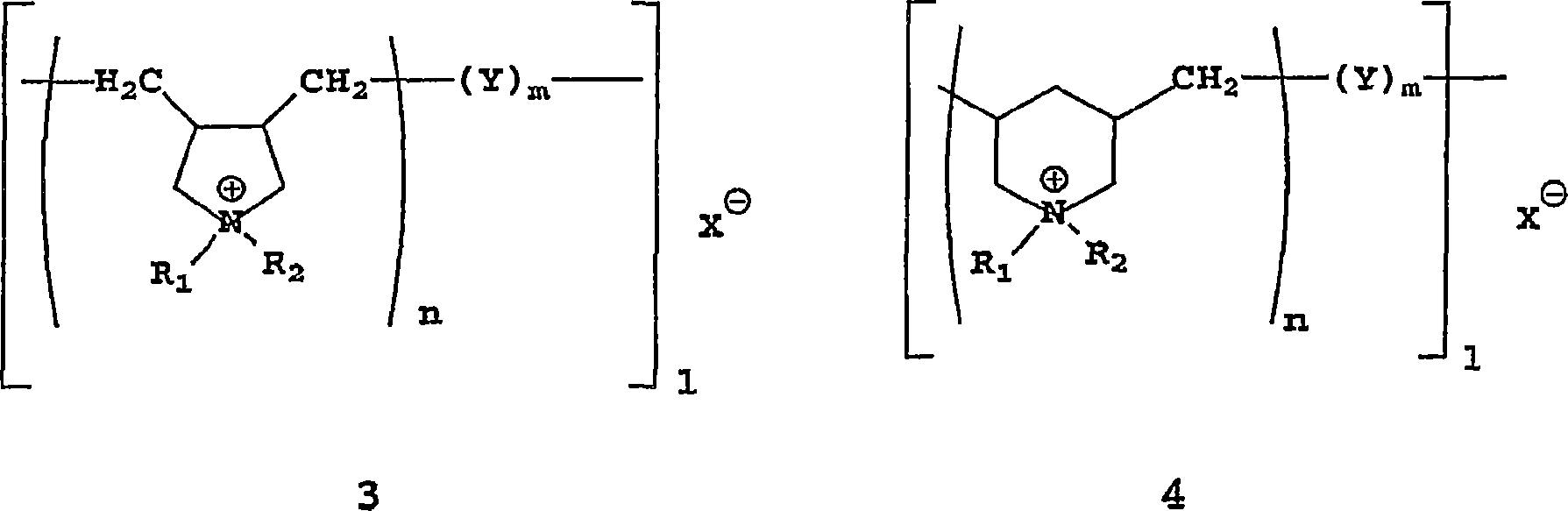

Dispersion for the chemical-mechanical polishing of metal surfaces containing metal oxide particles and a cationic polymer

A chemical mechanical and metal surface technology, applied in the field of dispersion, can solve the problems of slow metal removal rate, insufficient selectivity, and low dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Use Al in embodiment 1 2 o 3 Silicon-aluminum mixed oxide powder with a content of 66% by weight and a BET surface area of 90 m2 / g.

[0047] Use Al in embodiment 2 and 3 2 o 3 Silicon-aluminum mixed oxide powder with a content of 90% by weight and a BET surface area of 90 m2 / g.

[0048] Example 1:

[0049] 33.5 kg of demineralized water and 500 g of Catiofast(R) PR 8153 (BASF) were placed in a 60 liter stainless steel batch vessel. 5 kg of powder are sucked in and predispersed roughly by means of a dispersing and suction mixer (4500 rpm) supplied by Ystral. After introducing the powder, the dispersion was made using a Ystral Z 66 continuous rotor / stator homogenizer with 4 process rings, a stator slot width of 1 mm and a rotational speed of 11,500 rpm. During the introduction of the powder, the pH was maintained at 4.0 + / - 0.3 by the addition of acetic acid (100% glacial acetic acid). The abrasive concentration was brought to 12.5% by weight by adding furthe...

Embodiment 2

[0050] Example 2 was carried out in the same manner as Example 1.

Embodiment 3

[0051] Example 3 was also carried out in the same manner as Example 1, but without using the cationizing agent Catiofast(R).

[0052] Polishing tools and polishing parameters

[0053] Polisher: MECAPOL E460 (STEAG) with 46 cm platen and 6" wafer holder

[0054] Polishing pad: IC1400 (RODEL Corp); after each wafer polishing, the polishing pad is cleaned with a diamond tip

[0055] Amount of slurry: 120 ml / min for all experiments

[0056] Polishing parameters: p A Operating pressure: 10-125kPa=1.45-18.13psi The default is 45 and 60kPa

[0057] p R Back pressure is 10kPa

[0058] ω p = ω c = 40 rpm (constant for all experiments)

[0059] Sweep = 4 cm (constant for all experiments)

[0060] Polishing time: 2 minutes

[0061] Post-cleaning: After polishing, the wafers were rinsed in deionized water for 30 seconds, then both sides were cleaned in a scrubber unit with nebulizer and megasonic stand, and dried in a centrifugal dryer.

[0062] Starting from the dispersions fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com