Preparation method for porous PtAg@Pt octahedral nanoparticle

A nanoparticle and octahedral technology, which is applied in the field of preparation of porous PtAgPt octahedron, can solve problems such as reduction, and achieve the effects of high catalytic activity, excellent lasting stability and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

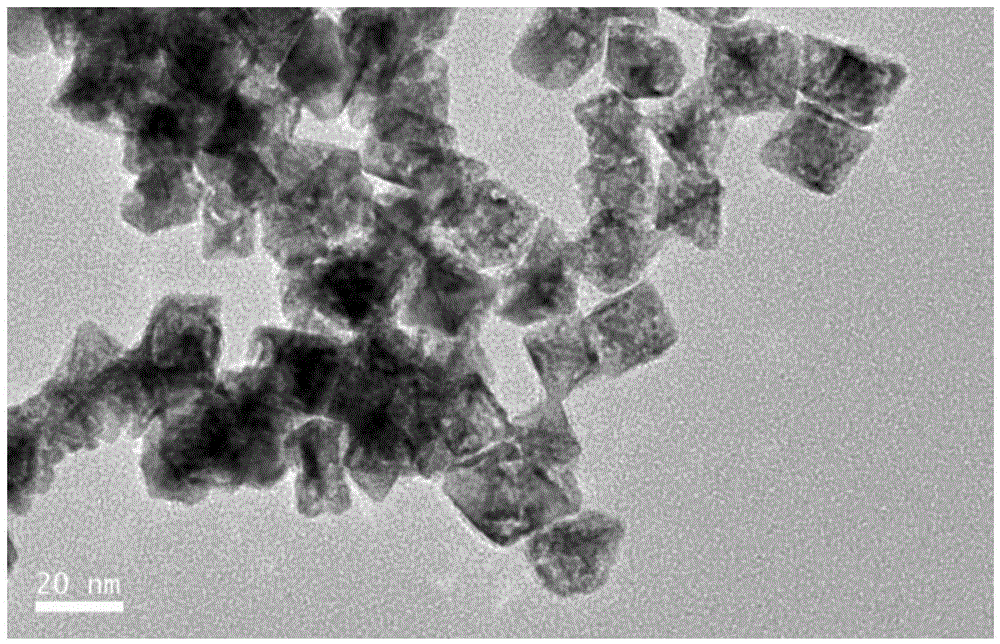

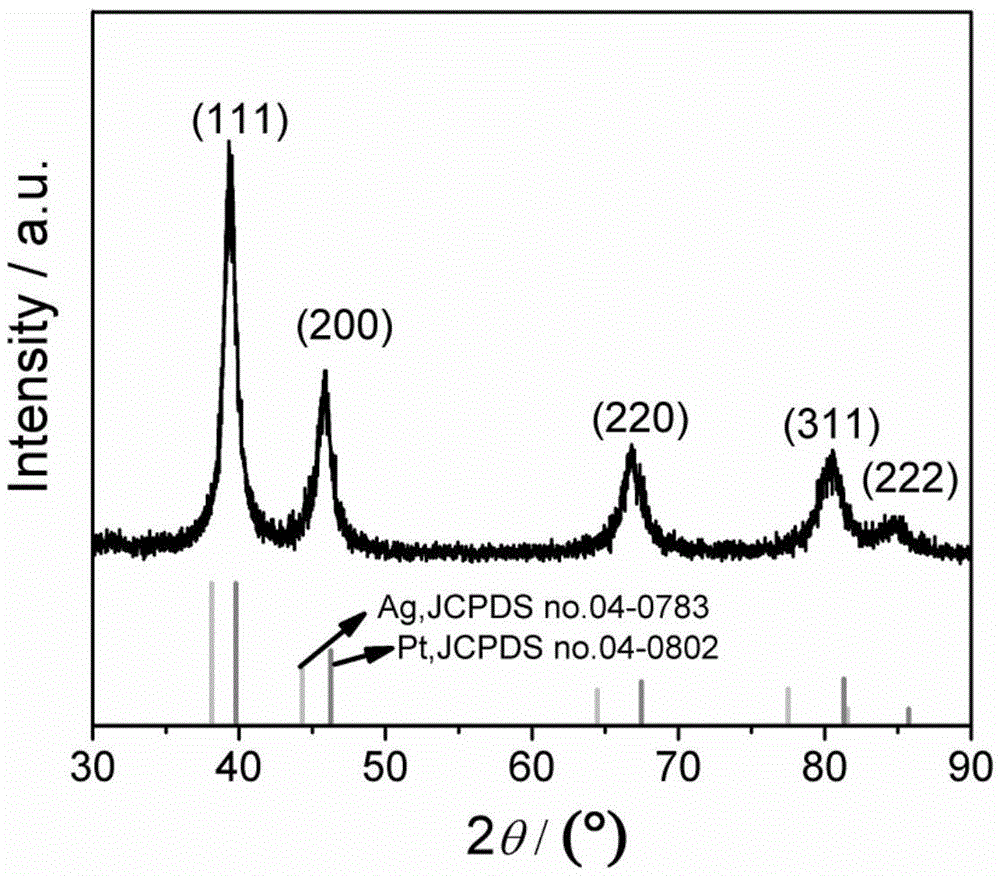

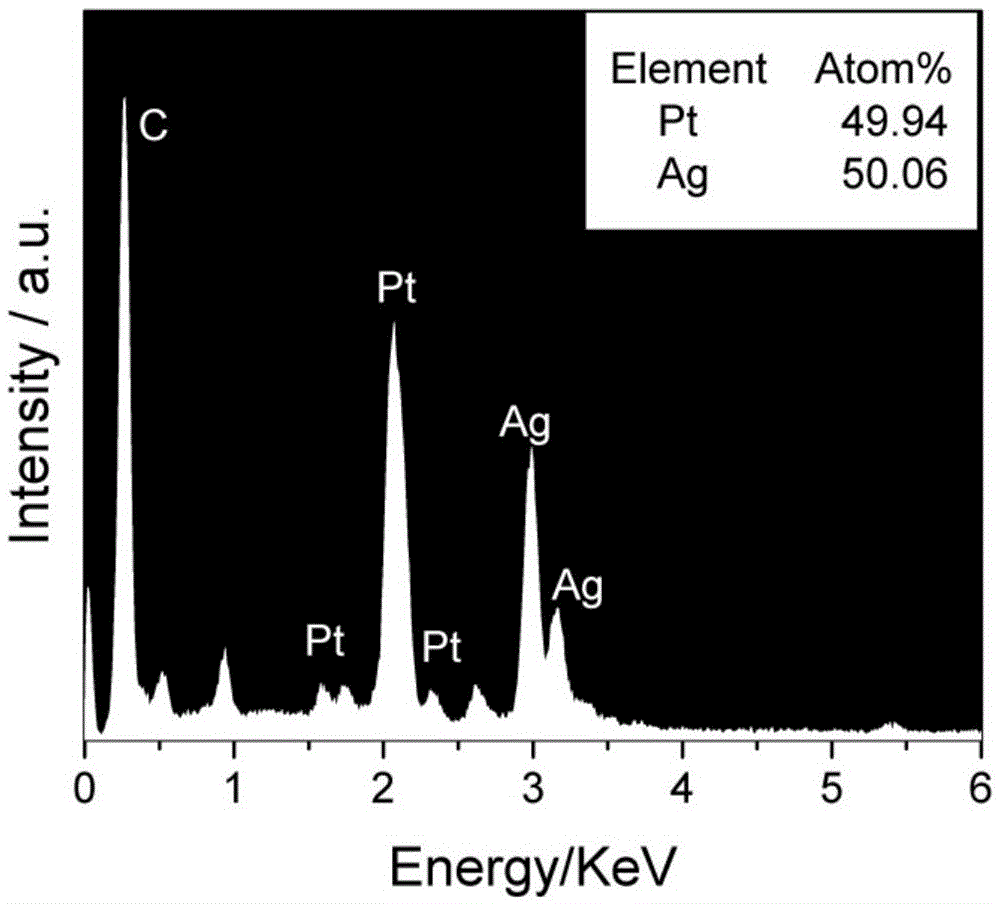

[0037] A preparation method of porous PtAgPt octahedral nanoparticles, comprising the following steps:

[0038] (1) Add 0.5mL of 0.05MK to 7.5mL of water successively under the condition of continuous stirring 2 PtCl 4 , 0.5mL0.05MAgNO 3 and 1.0mL0.50M polyallylamine hydrochloride (PAH, molecular weight 150000) solution (note: the PAH concentration value is calculated by the monomer concentration), during the stirring process, the reaction in the mixed solution generates PAH-Pt II Complexes, Ag + and Cl – The reaction produces a precipitate of AgCl.

[0039] (2) To contain PAH-Pt II Add 0.5ml HCHO (40%wt aqueous solution, the same below) to the mixed solution of the complex and AgCl, and then put it into a hydrothermal reaction kettle; place the reaction kettle in a drying oven at 180°C for 4h to make PAH-Pt II Complexes, AgCl precipitates react completely with HCHO, and after reduction, a Pt-Ag octahedral alloy is obtained. The product is centrifuged and washed to remov...

Embodiment 2

[0043] A preparation method of porous PtAgPt octahedral nanoparticles, comprising the following steps:

[0044] (1) Add 0.5mL of 0.05MK to 7.5mL of water successively under the condition of continuous stirring 2 PtCl 4 , 0.5mL0.05MAgNO 3 and 1.0mL0.50M polyallylamine hydrochloride (PAH, molecular weight 150000) solution, in the stirring process, the reaction in the mixed solution generates PAH-Pt II Complexes, Ag + and Cl – The reaction produces a precipitate of AgCl.

[0045] (2) To contain PAH-Pt II Add 0.5ml HCHO (40%wt aqueous solution, the same below) to the mixed solution of the complex and AgCl, and then put it into a hydrothermal reaction kettle; place the reaction kettle in a drying oven at 180°C for 4h to make PAH-Pt II Complexes, AgCl precipitates react completely with HCHO, and after reduction, a Pt-Ag octahedral alloy is obtained. The product is centrifuged and washed to remove the surfactant PAH on the particle surface.

[0046] (3) Add 5mL of concentrated...

Embodiment 3

[0049] A preparation method of porous PtAgPt octahedral nanoparticles, comprising the following steps:

[0050] (1) Add 0.5mL of 0.05MK to 7.5mL of water successively under the condition of continuous stirring 2 PtCl 4 , 0.5mL0.05MAgNO 3 and 1.0mL0.50M polyallylamine hydrochloride (PAH, molecular weight 150000) solution, in the stirring process, the reaction in the mixed solution generates PAH-Pt II Complexes, Ag + and Cl – The reaction produces a precipitate of AgCl.

[0051] (2) To contain PAH-Pt II Add 0.5ml HCHO (40%wt aqueous solution, the same below) to the mixed solution of the complex and AgCl, and then put it into a hydrothermal reaction kettle; place the reaction kettle in a drying oven at 180°C for 4h to make PAH-Pt II The complex, AgCl precipitate and HCHO react completely, and after reduction, a Pt-Ag octahedral alloy is obtained. The product is centrifuged and washed to remove the surfactant on the particle surface.

[0052] (3) Add 5 mL of concentrated ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com