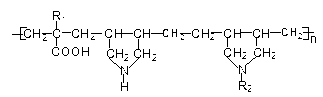

Amphiprotic amphiphilic leather retanning fatting agent and preparation method thereof

A retanning, fatliquoring and leather technology, applied in leather dipping, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve discoloration and poor copolymerization ability , poor fatliquoring performance and other problems, to achieve the effects of enhanced absorption, firm combination, excellent and durable softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ⑴ First, take 1-bromohexadecane and diallylamine respectively according to the molar ratio of 1:1, raise the temperature to 80°C, mix well, keep warm for 8 hours, remove unreacted substances by distillation under reduced pressure, and vacuum degree is 0.05 MPa, obtain N-hexadecyl diallylamine;

[0027] (2) Cool N-hexadecyl diallylamine to 40°C, add deionized water, the mass ratio of deionized water to N-hexadecyl diallylamine is 2:1, add formic acid to adjust the solution The pH is 2~3, obtains N-hexadecyl diallylamine formate solution;

[0028] (3) Add diallylamine to deionized water, the mass ratio of diallylamine to deionized water is 1:1, add formic acid to adjust the pH of the solution to 2-3, and obtain formate of diallylamine solution;

[0029] ⑷ Dissolve acrylic acid, N-hexadecyl diallylamine formate, and diallylamine formate in deionized water according to the mass ratio of 100:50:15. 4 times the mass, heat up to 80°C, mix well, add 1.5% ammonium persulfate ...

Embodiment 2

[0031] ⑴ First, take 1-bromododecane and diallylamine respectively according to the molar ratio of 1:1, raise the temperature to 80°C, mix well, keep warm for 10 hours, remove unreacted substances by distillation under reduced pressure, and the vacuum degree is 0.05 MPa, obtain N-dodecyl diallylamine;

[0032] (2) Cool N-dodecyl diallylamine to 40°C, add deionized water, the mass ratio of deionized water to N-dodecyl diallyl amine is 2:1, add acetic acid to adjust the solution The pH is 2~3, obtains N- dodecyl diallyl amine acetate solution;

[0033] (3) Add diallylamine to deionized water, the mass ratio of diallylamine to deionized water is 1:1, add acetic acid to adjust the pH of the solution to 2-3, and obtain acetate of diallylamine solution.

[0034] ⑷ Dissolve methacrylic acid, N-dodecyl diallylamine acetate, and diallylamine acetate in deionized water according to the mass ratio of 100:50:10, and the quality of deionized water is one 4 times the total mass of the mo...

Embodiment 3

[0036] ⑴ First, take 1-bromooctane and diallylamine respectively according to the molar ratio of 1:1.05, raise the temperature to 80°C, mix well, keep it warm for 8 hours, and distill under reduced pressure to remove unreacted substances, the vacuum degree is 0.05MPa , to obtain N-octyldiallylamine;

[0037] (2) Cool N-octyldiallylamine to 40°C, add deionized water, the mass ratio of deionized water to N-octyldiallylamine is 1:1, add formic acid to adjust the pH of the solution 2 to 3 to obtain N-octylalkyldiallylamine formate solution;

[0038] (3) Add diallylamine to deionized water, the mass ratio of diallylamine to deionized water is 1:1, add formic acid to adjust the pH of the solution to 2-3, and obtain formate of diallylamine solution.

[0039] (4) Dissolve methacrylic acid, N-octyl diallylamine formate, and diallylamine formate in deionized water according to the mass ratio of 100:80:20, and the quality of deionized water is unit 5 times the total mass of the monome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com