Amidated graphene oxide modified polycarboxylate superplasticizer and preparation method thereof

A technology of graphene modification and polycarboxylic acid, which is applied in the field of material chemical industry, can solve the problems that graphene oxide is easy to agglomerate and affect the performance of concrete, and achieve stable product performance, good water reducing effect and high water reducing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

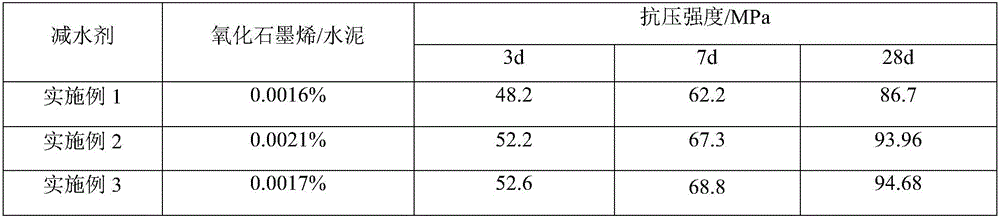

Examples

Embodiment 1

[0036] An amidated graphene oxide modified polycarboxylate water reducer, its raw material components are as follows by mass fraction: graphene oxide 0.141% (0.1g), methallyl polyoxyethylene ether 16.908% (12g) , Acrylic acid 1.014% (1.08g), maleic anhydride 1.036% (0.735g), allylamine 0.201% (0.1425g), water 80.306% (57.305g), oxidant 0.268% (0.19g), reducing agent 0.059% (0.042g), EDC hydrochloride 0.006% (0.0045g), NHS 0.004% (0.003g).

[0037] The preparation method of above-mentioned amidated graphene oxide modified polycarboxylate water reducer, concrete steps are as follows:

[0038] (1) Weigh 4.5mg of EDC.HCL into a 25ml beaker, add 5ml of water to it and stir thoroughly, then add 3mg of NHS to the mixed solution, stir thoroughly and ultrasonically for 10 minutes to obtain carboxyl activation solution;

[0039] (2) Take 34.48g mass fraction of 0.29% graphene oxide aqueous solution in the reactor, add the obtained carboxyl activation solution in step (1) while stirring...

Embodiment 2

[0044] A kind of amidated graphene oxide modified polycarboxylate water reducer, its raw material components are as follows by mass fraction: graphene oxide 0.181% (0.2g), methallyl polyoxyethylene ether 10.861% (12g) , Acrylic acid 0.652% (0.72g), maleic anhydride 0.665% (0.735g), allylamine 0.129% (0.1425g), water 87.275% (96.425g), oxidant 0.172% (0.19g), reducing agent 0.038% (0.042g), EDC hydrochloride 0.016% (0.018g), NHS 0.011% (0.012g).

[0045] The preparation method of above-mentioned amidated graphene oxide modified polycarboxylate water reducer, concrete steps are as follows:

[0046] (1) Weigh 18mgEDC.HCL and put it into a 25ml beaker, add 20ml of water to it and stir thoroughly, then add 12mgNHS to the mixed solution, stir well and ultrasonicate for 10 minutes to obtain carboxyl activation solution;

[0047] (2) Take 68.96g mass fraction of 0.29% graphene oxide aqueous solution in the reactor, add the obtained carboxyl activation solution in step (1) while stirr...

Embodiment 3

[0052] An amidated graphene oxide modified polycarboxylate water reducer, its raw material components are as follows by mass fraction: graphene oxide 0.142% (0.1g), methallyl polyoxyethylene ether 16.991% (12g) , Acrylic acid 1.019% (0.72g), maleic anhydride 0.694% (0.49g), allylamine 0.404% (0.1425g), water 80.411% (56.79g), oxidizing agent 0.269% (0.19g), reducing agent 0.059% (0.042g), EDC hydrochloride 0.006% (0.0045g), NHS 0.004% (0.003g).

[0053] The preparation method of above-mentioned amidated graphene oxide modified polycarboxylate water reducer, concrete steps are as follows:

[0054] (1) Weigh 4.5mg of EDC.HCL and put it in a 25ml beaker, add 20ml of water to it and stir thoroughly, then add 3mg of NHS to the mixed solution, stir thoroughly and ultrasonically for 10 minutes to obtain carboxyl activation solution;

[0055] (2) Take 34.48g mass fraction of 0.29% graphene oxide aqueous solution in the reactor, add the obtained carboxyl activation solution in step (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com