Light-emitting device

A technology for lighting devices and substrates, applied to electrical components, electrical solid devices, circuits, etc., can solve problems such as failure to obtain predetermined reflection efficiency, damage to optical properties, and formation of metal films, so as to improve light extraction efficiency and inhibit peeling , the effect of reducing the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, various embodiments of the present invention will be described with reference to the drawings.

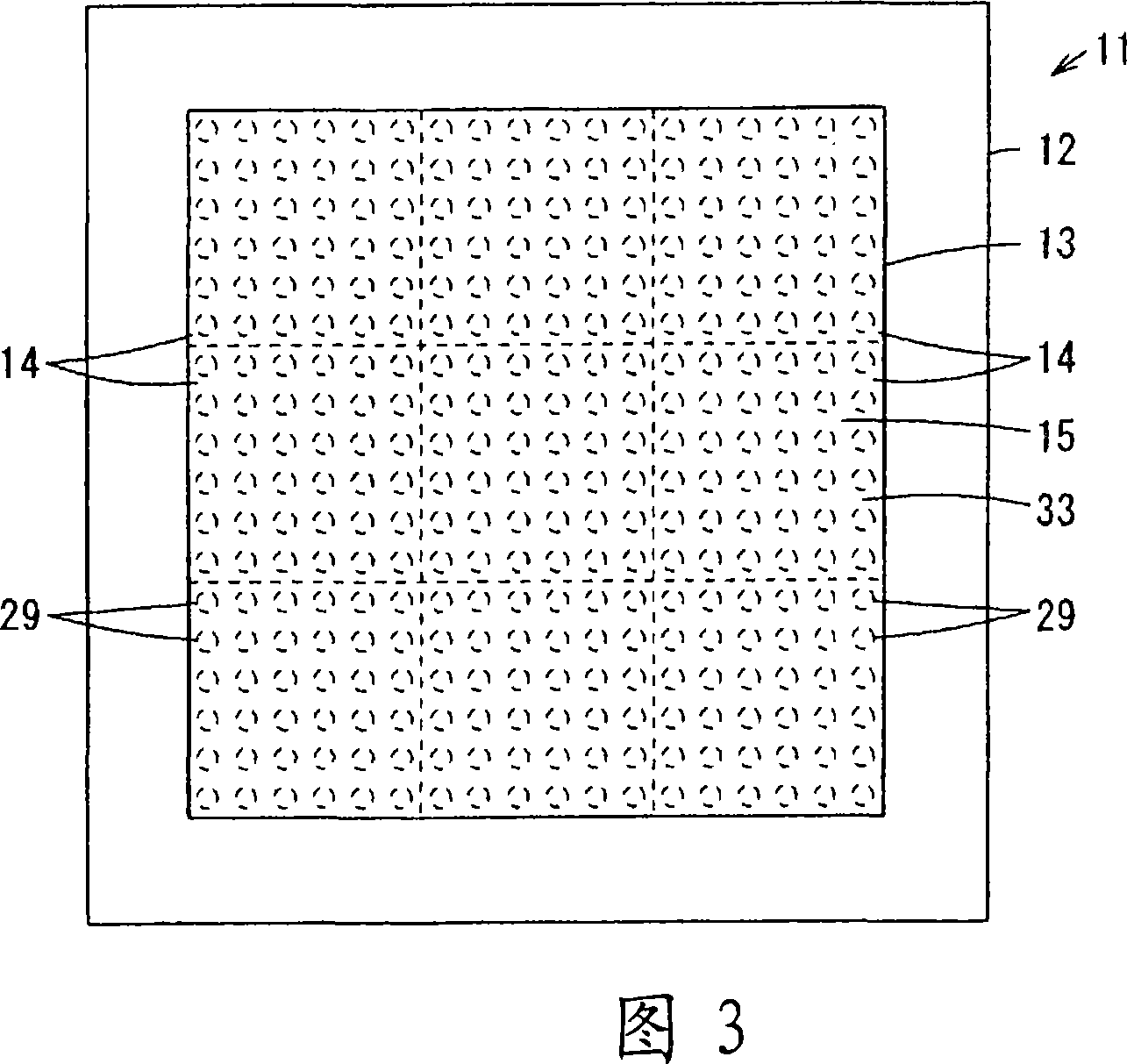

[0048] 1 to 4 show the first embodiment, FIG. 1 is a cross-sectional view of the light emitting module of the lighting device, FIG. 2 is a front view of the light emitting module, FIG. 3 is a front view of the lighting device, and FIG. 4 is a combination of materials of the light emitting module An illustration of an example.

[0049] In Fig. 3, 11 is an illuminating device, and this illuminating device 11 has the equipment main body 12 that is formed in quadrangular shape and thin shape, is formed with quadrangular opening 13 on the surface of this equipment main body 12, and the inside of this opening 13 is matrix-like. A plurality of quadrangular light-emitting modules 14 are arranged in an orderly manner, and the light-emitting surface 15 is formed by these plurality of light-emitting modules 14 .

[0050] As shown in FIG. 1 , each light-emitting module 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com