Nanometer fluid and its prepn process

A nanofluid and carbon nanotube technology, applied in the field of heat transfer, can solve problems such as hindering heat conduction, pipe blockage, and changes in heat conduction performance, achieving good dispersion, avoiding pipe blockage, and excellent heat conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

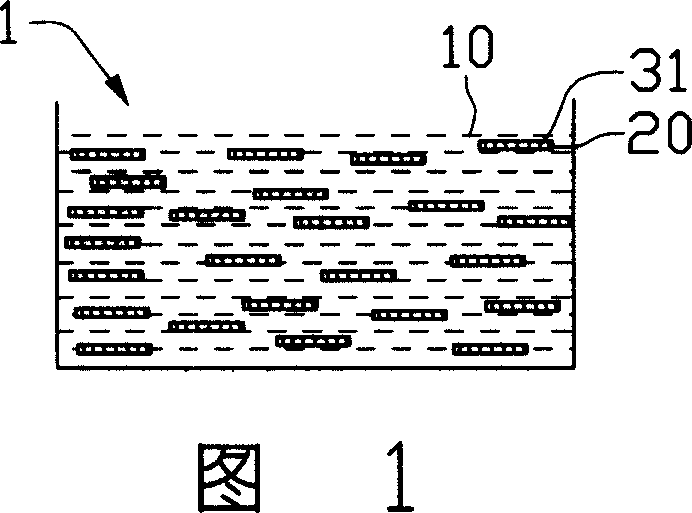

Image

Examples

preparation example Construction

[0023] The preparation method of the nanofluid provided by the invention comprises the following steps:

[0024] Step (a): providing a plurality of carbon nanotubes;

[0025] Step (b): mixing the carbon nanotubes with a solution of positively charged polymers and reacting, so that the surface of the carbon nanotubes is linked to positively charged polymers;

[0026] Step (c): separating carbon nanotubes from the mixed solution after the reaction;

[0027] Step (d): dispersing the separated carbon nanotubes in a liquid medium to form a nanofluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com