Process for preparing amlodipine benzenesulphonate

A technology of dipine benzene sulfonate and amino group, applied in the field of preparing amlodipine benzene sulfonate represented by the general formula, can solve the problems such as difficult to realize industrialization, difficult product purification, difficult removal of amino protecting group, etc. Stable, avoid deprotection step, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

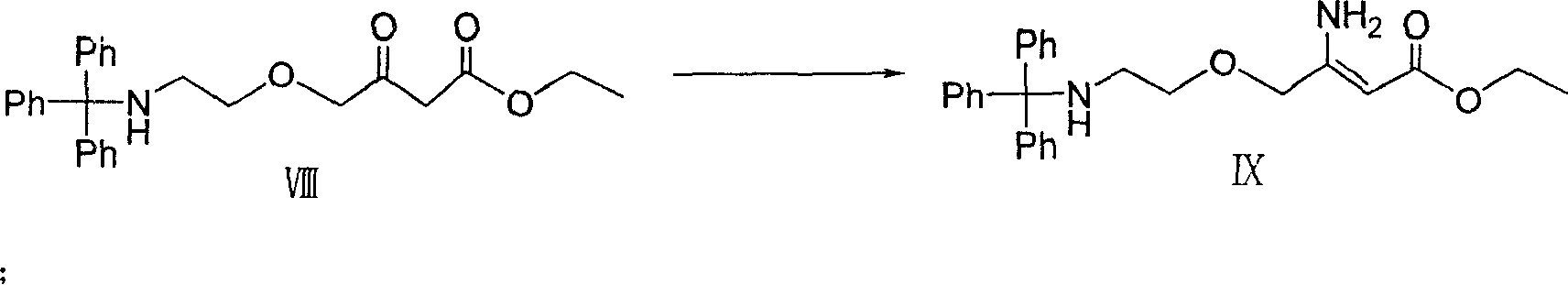

[0039] Preparation of ethyl 3-amino-4-[2-(tritylamino)ethoxy]crotonate (IX)

[0040] In a 500mL round bottom bottle equipped with an oil-water separator, add ethyl 4-[2-(tritylamino)ethoxy]acetoacetate (VIII) (86.2g, 0.02mol) and 300mL of toluene, The reactant was dissolved under stirring, and then ammonium acetate (7.7 g, 0.1 mol) was added to the reaction system, and the reaction was slowly heated to reflux for dehydration, and the reaction was maintained for 6 hours. Cool the reaction system, add the reactants to 500mL of ice water, extract by layers, and then extract the water layer with 200mL of toluene, combine the organic phases, wash with water, dry and concentrate to obtain a crude product. Yield 75.0%, HPLC: 88%, m.p.116~117℃, 1 H NMR (CDCl 3 , 300MHz) δ: 1.27(t, J=5.4Hz, 3H), 2.26~2.38(m, 2H), 3.56~3.58(m, 2H), 3.99(s, 3H), 4.13(q, J 1 =5.1Hz,J 2 =10.5Hz, 2H), 4, 52(s, 1H), 7.20(t, J=5.1Hz, 3H), 7.28(t, J=5.4Hz, 6H), 7.48(d, J=6.0Hz, 6H ).MS (70eV) m / z (%): 432 (...

Embodiment 2

[0042] Preparation of ethyl 3-amino-4-[2-(tritylamino)ethoxy]crotonate (IX)

[0043] In a 500mL round bottom flask equipped with an oil-water separator, add 4-[2-(tritylamino)ethoxy]ethyl acetoacetate (VIII) (86.2g, 0.02mol) and cyclohexane 350mL, stirred to dissolve the reactant, then added ammonium acetate (7.7g, 0.1mol) to the reaction system, slowly heated the reaction to reflux for dehydration, and maintained the reaction for 6h. Cool the reaction system, add the reactant to 500 mL of ice water, extract by layers, and extract the water layer with 200 mL of cyclohexane, combine the organic phases, wash with water, dry and concentrate to obtain a crude product. Yield 76.0%, HPLC: 88%.

Embodiment 3

[0045] Preparation of ethyl 3-amino-4-[2-(tritylamino)ethoxy]crotonate (IX)

[0046] In a 500mL round bottom bottle, add 4-[2-(tritylamino)ethoxy]ethyl acetoacetate (VIII) (86.2g, 0.02mol) and methanol 300mL, dissolve the reactant under stirring, Ammonium acetate (7.7 g, 0.1 mol) was added to the reaction system, and the reaction was kept stirring at room temperature for 16 h. Concentrate under reduced pressure and recover methanol, add 500 mL of water and 500 mL of dichloromethane to extract the residue, dry and concentrate the organic phase to obtain a crude product with a yield of 78%, HPLC: 91%, and the physical and chemical data of the product are the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com