Preparation method and apparatus of nano porous biologic ceramics

A bioceramic and nanoporous technology, which is applied in ceramic products, bone implants, applications, etc., can solve the problem of microwave sintering hindered hot spots, thermal runaway of cracking and non-uniform heating, pore size that cannot meet the requirements of bone tissue, and complicated thermal insulation chamber devices. and other problems, to achieve the effect of uniform grain size distribution, reduced drying process and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

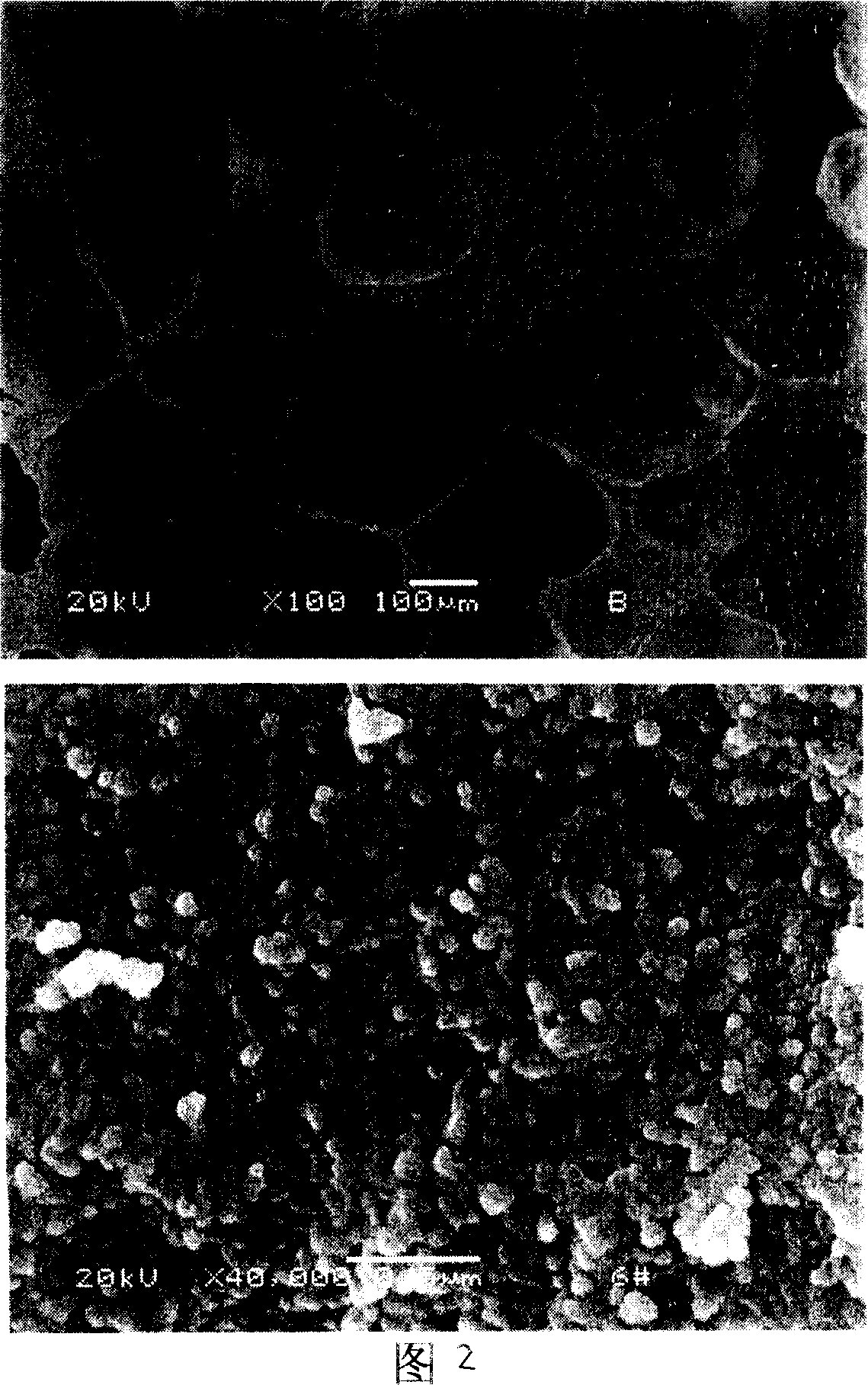

[0031] Measure 160ml of 1.0M calcium nitrate solution into a 400ml beaker, control the reaction temperature at 60°C, add ammonia water dropwise to adjust the pH value to 9.0, then add concentrated ammonia water and 1.0M phosphoric acid dropwise under constant stirring 100 ml of diammonium hydrogen solution to maintain the pH at 9.0. After the addition, stop and stir for 30 minutes, let stand and age for 24 hours (keep the reaction temperature unchanged), and centrifugally wash the powder until the pH value is 7.0. Add about 10 ml of 5% hydrogen peroxide and 1 g of polyethylene glycol to the powder slurry to make a flowable slurry, move it into a mold and place it in an oven for molding at a molding temperature of 30-120°C. The porous green body can be obtained by demolding and biscuiting at 400°C.

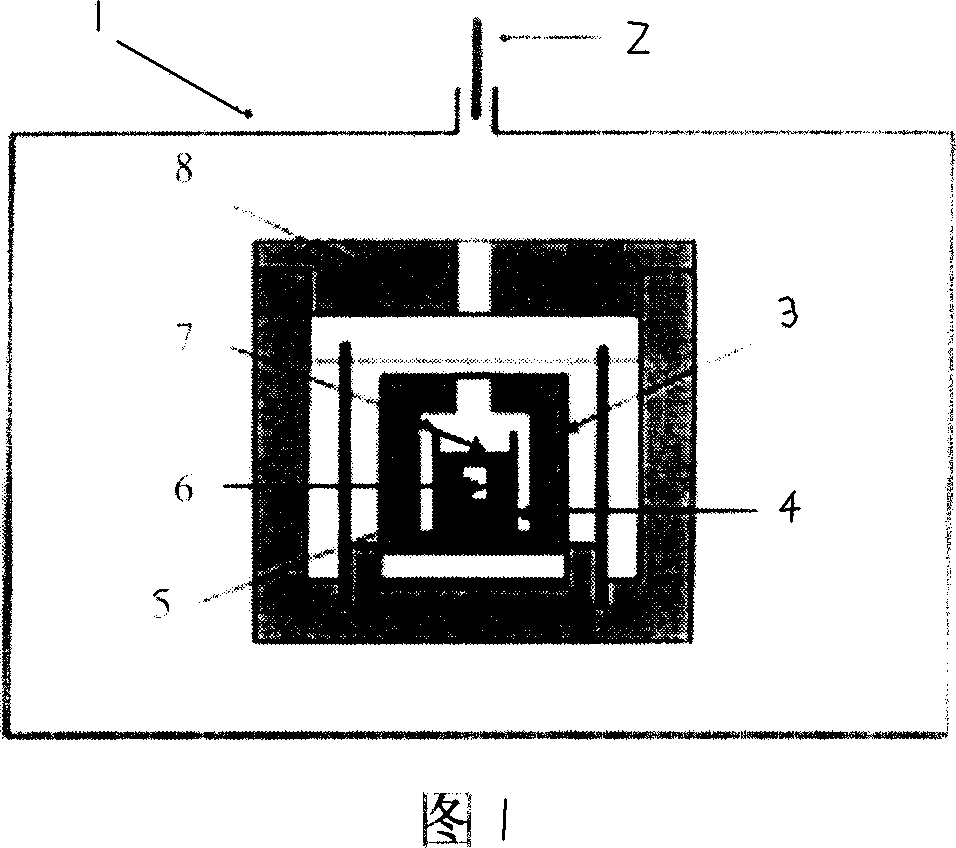

[0032] The porous green body is placed in the SiC sintering container, and the SiC powder is used as the sintering medium, and the microwave sintering is carried out in the air at...

Embodiment 2

[0034] Take about 10 grams of commercial nano-scale titanium dioxide powder, add about 10 grams of water to make a slurry, and add about 5 ml of 5% hydrogen peroxide and 1 gram of polyvinyl alcohol to the slurry to make a flowable slurry, and transfer it to The molds are placed in an oven for molding, and the molding temperature is 30-120°C. The porous green body can be obtained by demolding and biscuiting at 400°C.

[0035] The porous green body is placed in a SiC sintering container, and titanium dioxide powder is used as a sintering medium for microwave sintering in an air atmosphere. The heating rate was set at 30°C / min. After the temperature rose to 900°C, the temperature was kept for 5 minutes. The cooling rate was set at 80°C / min. After the sample was cooled to room temperature, the porosity of the sample was measured to be 60%. The compressive strength is about 18MPa, and the grain size is 50-70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com