Degradation type composite material

A composite material and polymer technology, which is applied in the field of degradable composite materials to achieve the effects of good compatibility, improved physical properties and good opening.

Active Publication Date: 2010-11-10

吉林金源北方科技发展有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Carbon dioxide polymer 100 parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

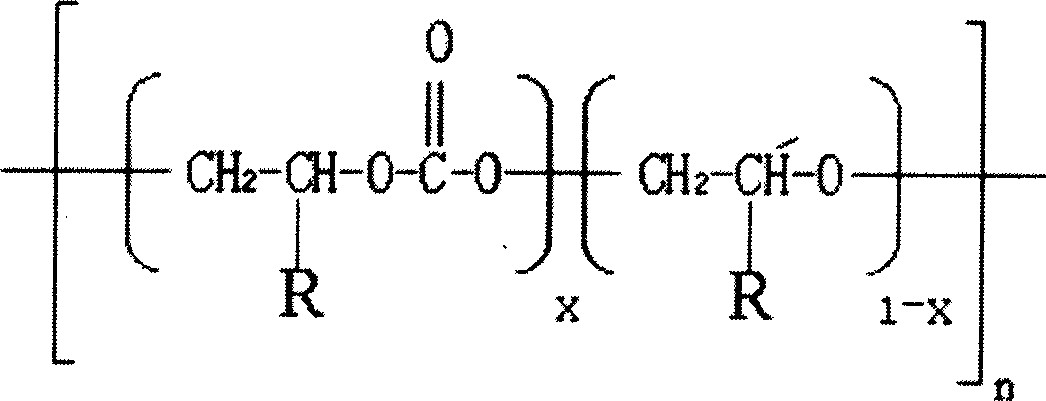

The invention discloses a decomposable composite material, which comprises the following parts: carbon dioxide polymer, 10-30% polysuccinic polybutanediol ester (PBS), 0-10% plasticizer and 1-5% capping agent.

Description

Degradable composite material Technical field The invention relates to a composite material, in particular to a degradable composite material. Background technique We know that the existing composite materials used in disposable medical infusion bags and infusion equipment are generally prepared by five-layer or seven-layer co-extrusion method, in which polyvinyl chloride or polyvinylidene chloride is the barrier layer, polyethylene, poly Acrylic is used as a protective layer, and two bonding layers are needed in between. The barrier layer is used to isolate oxygen and water vapor. At present, the barrier layer of disposable medical materials generally uses polyvinyl chloride. However, processing aids must be used in the processing of PVC, and there are problems with the precipitation of additives during use and storage, which affect the health of patients. Moreover, for medical materials, incineration is generally required, while polyvinyl chloride is prone to produce hydro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L69/00

Inventor 冯超

Owner 吉林金源北方科技发展有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com