Toughness porous anodic aluminium oxide film and preparation method thereof

A technology of alumina membrane and porous anode, applied in the fields of electrochemistry and material chemistry, can solve the problem of difficult to prepare large area, and achieve the effect of uniform pore size distribution, simple steps and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

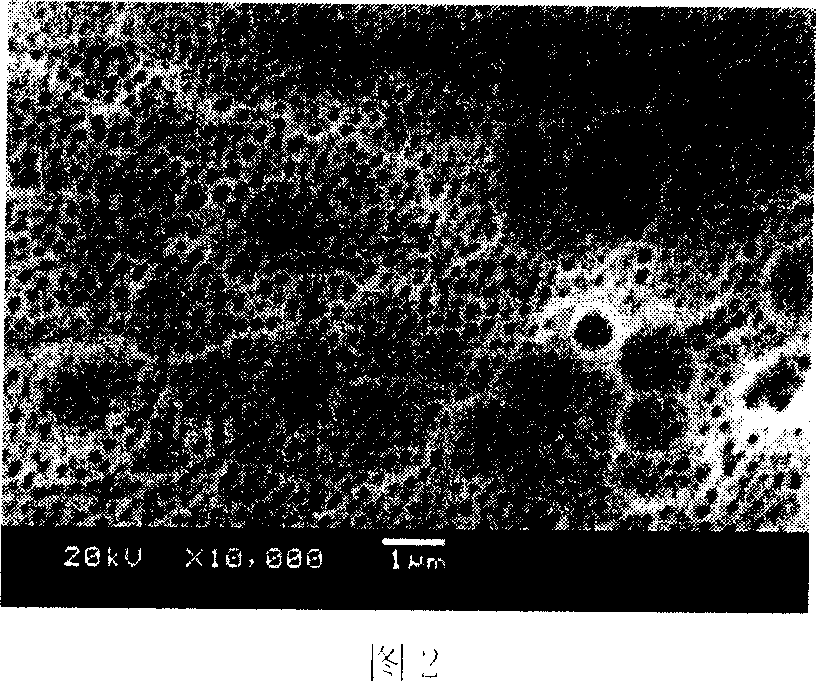

[0011] Example 1: After degreasing an aluminum sheet with acetone, soak it in 1% NaOH for 12 minutes, wash it with deionized water and put it in H2O with a volume ratio of 5:4:1. 3 PO 4 :H 2 SO 4 : HNO 3 Chemically polish for 3 minutes at 80°C in mixed acid, take it out and rinse it with deionized water, put it into 0.3mol / l sulfuric acid, aluminum sheet as anode, platinum wire as cathode, 10V, single-side oxidation at 25°C for 3 hours, and vigorously stir at the same time . The anodized film is used as the anode again, the platinum wire is still the cathode, and the electrolyte is 1% hydrochloric acid and 5g / l ferric chloride.

[0012] The aluminum substrate on the other side of the film is exposed to the electrolyte for single-sided electrolysis, the electrolysis time is 9min, the temperature is 25°C, and the current density is 0.4A / cm 2 . Soak in 6% phosphoric acid for 30 minutes at 30°C to remove the barrier layer. A porous anodized aluminum oxide film with toughnes...

Embodiment 2

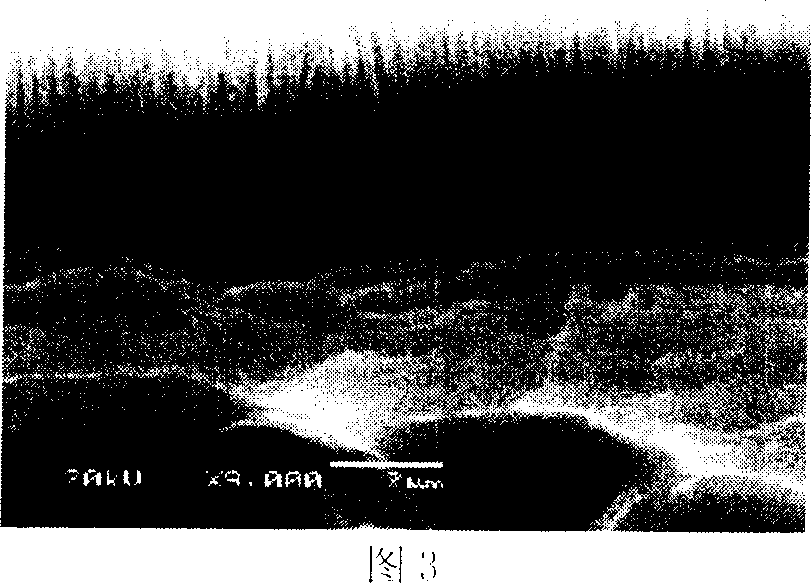

[0013] Example 2: Take an aluminum sheet and degrease it with acetone, soak it in 5% NaOH for 8 minutes, wash it with deionized water and put it into H2O with a volume ratio of 5:4:1 3 PO 4 :H 2 SO 4 : HNO 3 Chemically polish at 80°C for 3 minutes in mixed acid, take it out and rinse it with deionized water, put it into 0.5mol / l oxalic acid, aluminum sheet as anode, platinum wire as cathode, 40V, single-side oxidation at 0°C for 5 hours, and vigorously stir at the same time . The anodized film is used as the anode again, the platinum wire is still the cathode, the electrolyte is 4% hydrochloric acid and 40g / l ferric chloride, and the aluminum substrate on the other side of the film is in contact with the electrolyte for single-sided electrolysis. 25℃, current density 0.5A / cm 2 . Soak in 3% phosphoric acid for 50 minutes at a temperature of 30°C to remove the barrier layer. A porous anodized aluminum oxide film with toughness penetrating on both sides can be obtained.

Embodiment 3

[0014] Example 3: Take an aluminum sheet and degrease it with acetone, soak it in 8% NaOH for 4 minutes, wash it with deionized water and put it into H2O with a volume ratio of 5:4:1 3 PO 4 :H 2 SO 4 : HNO 3 Chemical polishing at 80°C for 3 minutes in mixed acid, take it out and rinse with deionized water, put it into 0.4mol / l phosphoric acid, aluminum sheet as anode, platinum wire as cathode, 130V, single-side oxidation at 20°C for 1 hour, and vigorously stir at the same time . The anodized film is used as the anode again, the platinum wire is still the cathode, the electrolyte is 3% hydrochloric acid and 20g / l ferric chloride, and the aluminum substrate on the other side of the film is in contact with the electrolyte for single-sided electrolysis. 15℃, current density 0.04A / cm 2 . Soak in 5% phosphoric acid for 40 minutes at a temperature of 30°C to remove the barrier layer. A porous anodized aluminum oxide film with toughness penetrating on both sides can be obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com