Flexible distributed manufacturing method and system therefor

A technology of machines and parts, applied in the field of flexible distributed manufacturing methods and systems thereof, can solve the problems of limited handling process of special manufacturing systems and inability to automatically adopt manufacturing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

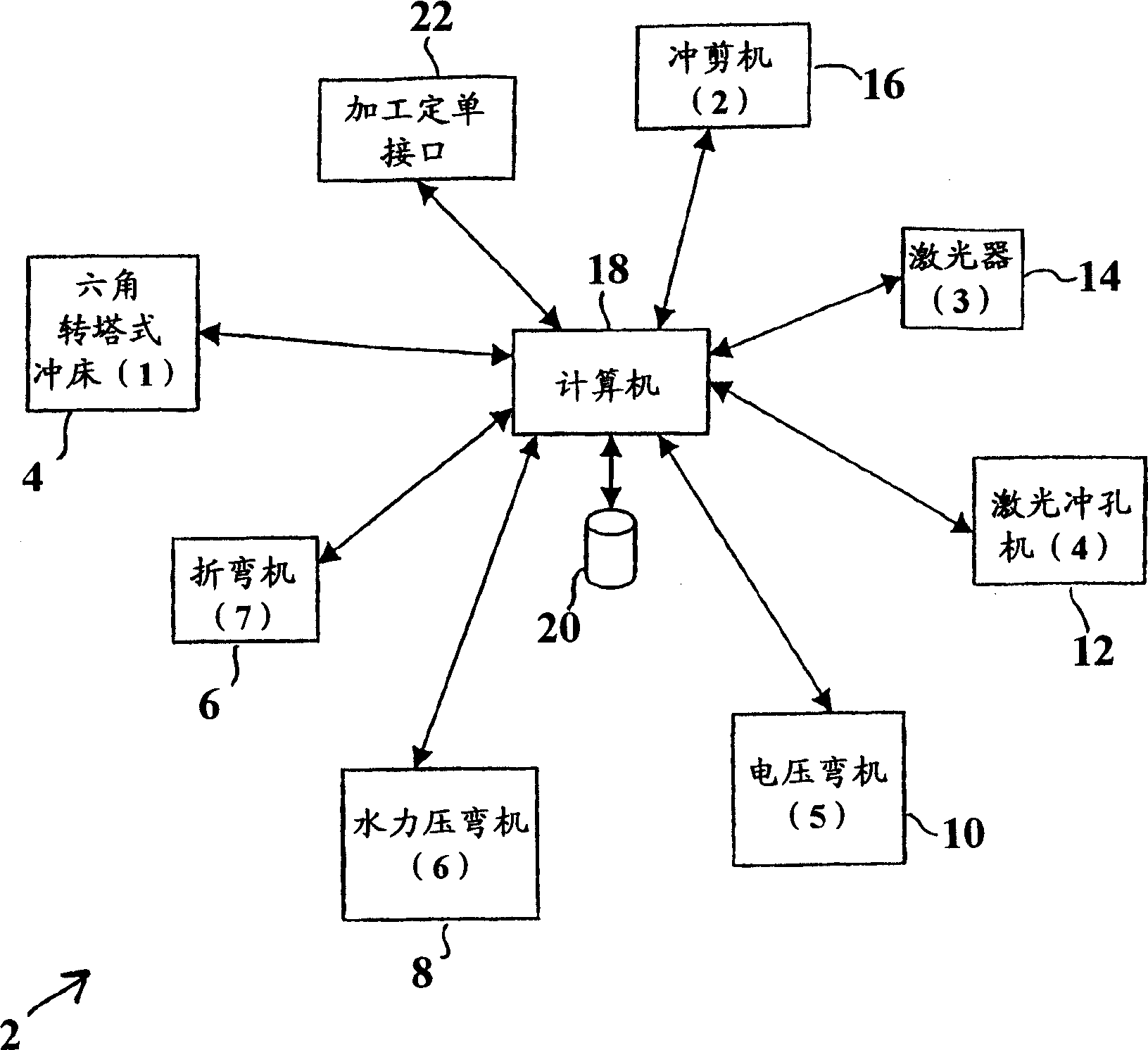

[0023] figure 1 A distributed flexible manufacturing system is illustrated. As shown, the exemplary manufacturing system 2 includes a hexagonal turret punch press 4 , a press brake 6 , a hydraulic press brake 8 , a voltage brake 10 , a laser punch 12 , a laser cutter 14 , and a punch 16 . Each of these machines is connected to a central processing computer 18 . It should be noted that in practice computer 18 may represent figure 1 Each CNC controller or any one of the CNC controllers in each sheet material processing machine of the embodiment.

[0024]Connected to computer 18 is memory 20 . The memory 20 (rather than the central processing unit) may also represent the various memories resident in various sheet metal processing machines, which function in conjunction with the resident CNC controller in those machines. A fabrication order interface 22 is also connected to the computer 18 for receiving incoming orders to form sheets. Such interfaces may include conventiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com