Systems for preparing fine particles and other substances

A particle and material technology, applied in the field of control preparation, can solve the problems of reducing crystallinity, nozzle clogging and amplification difficulties, and SAS technology is not suitable for large-scale reaction systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Described in Example 1.

[0095] According to an important embodiment of the present invention, said material in said one or more zones within the vessel on which said elementary particles are deposited comprises the end product. A non-limiting example of such a product according to this embodiment includes a tape cast having said elementary particles deposited on a carrier film. Alternatively said elementary particles on said surface of said material constitute a film or coating.

[0096] According to a particularly preferred embodiment of the invention, the film or coating has one or more layers, each layer having a layer thickness of at most 1 micron, such as a layer thickness of less than 500 nm. Preference is given to layer thicknesses of less than 250 nm, such as layer thicknesses of less than 100 nm. More preferably the film has a layer thickness of less than 50 nm, such as a layer thickness of less than 30 nm. Furthermore, the coating or film on the material ...

Embodiment approach

[0107] The invention is applicable to the manufacture of fine particles of a wide range of materials. According to a preferred embodiment of the present invention, it includes the manufacture of primary particles, wherein said primary particles include: oxides, oxyhydroxides, hydroxides such as metal oxides, semi-metal oxides, metal oxyhydroxides, semi-metal oxyhydroxides compounds, metal hydroxides, semimetal hydroxides, and combinations thereof.

[0108] According to this preferred embodiment of the present invention, oxide materials are further included, such as: electro-ceramic materials, semiconductor materials, piezoelectric materials and magnetic, ferromagnetic, paramagnetic, or superparamagnetic materials.

[0109] In a particularly preferred embodiment according to the invention, the oxide material may comprise oxides of one or more of the following elements: Al, Si, Ti, Zr, Zn, Fe, Ni, Co, Ce, Ge, Ba , Sr, W, La, Ta, Y, Mn, V, Bi, Sn, Te, Se, Ga, Be, Pb, Cr, Mg, Ca,...

Embodiment 2

[0200] A device according to an embodiment of the present invention may include:

[0201] ■Reaction vessel components;

[0202] ■ Feeding components for precursors and chemical reactors;

[0203] ■CO 2 circulatory system;

[0204] ■Inner discharge components;

[0205] ■External filter and product collection components

[0206] ■CO 2 Tank Components

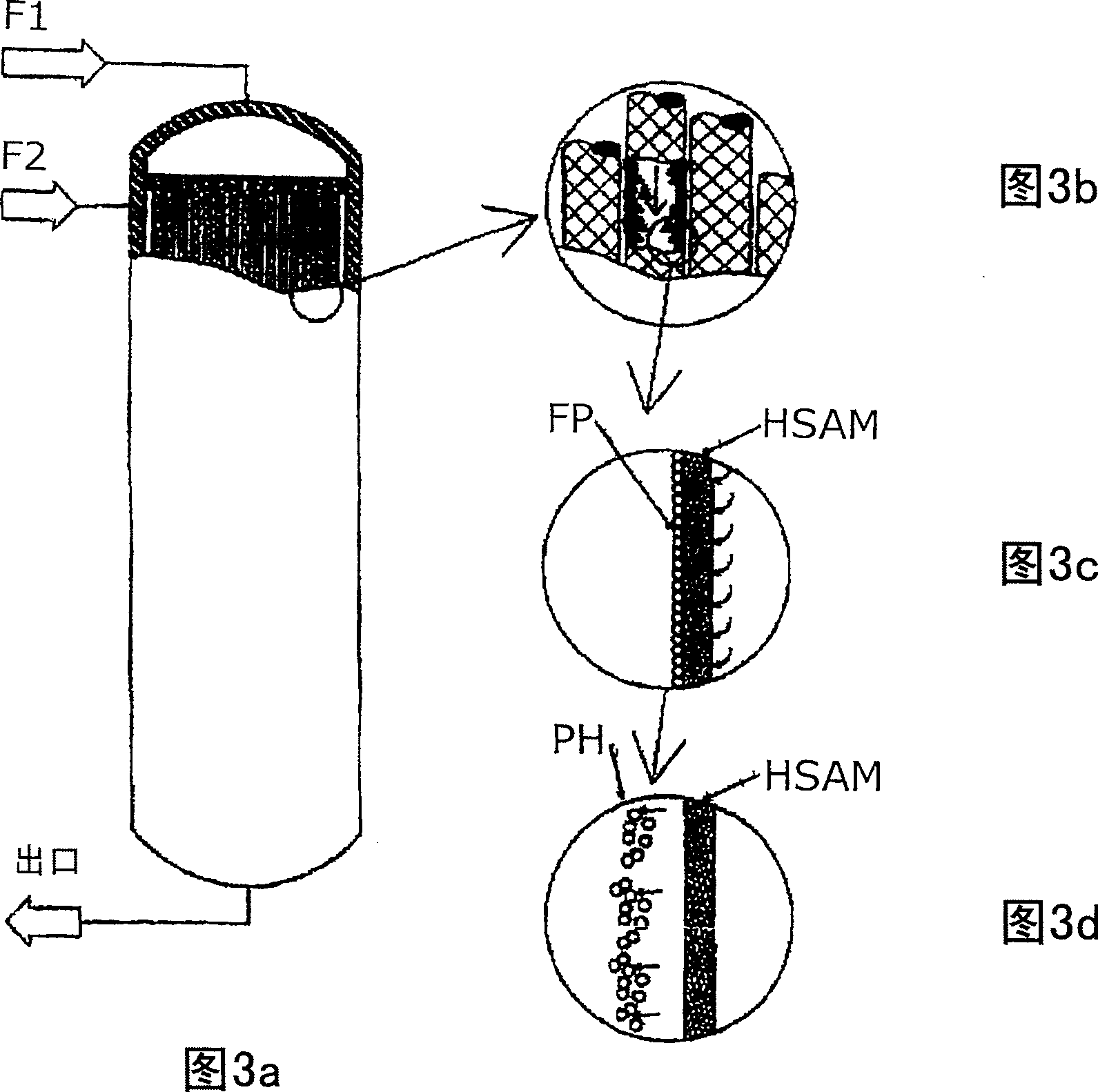

[0207] The reaction vessel can be a vertical or horizontal vessel. In a preferred embodiment vertical vessels are used for small production scale plants and horizontal vessels are preferably used for large production scale plants. It is up to the person skilled in the art, in each case, to arrange the containers in parallel in order to optimize the plant layout.

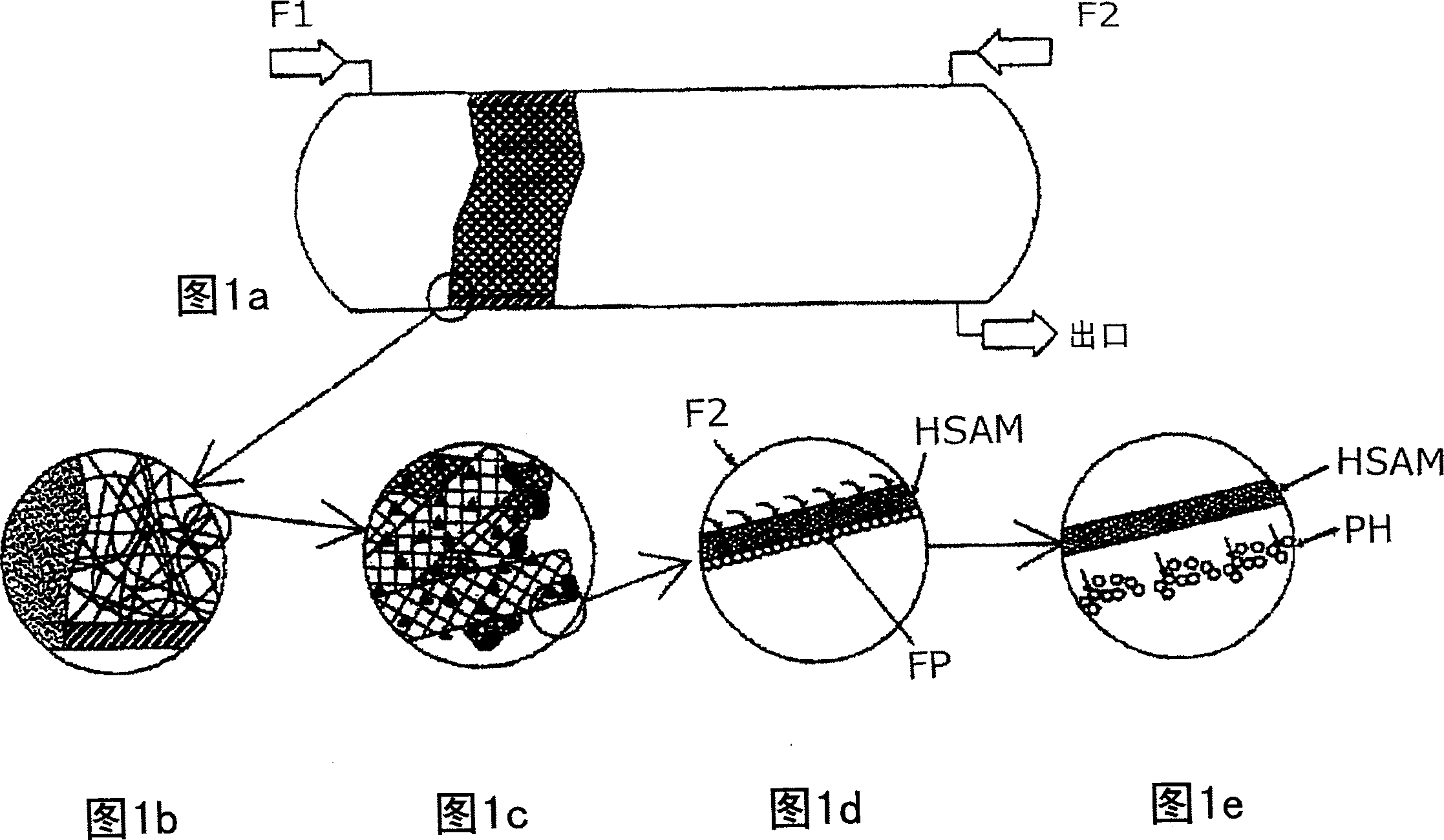

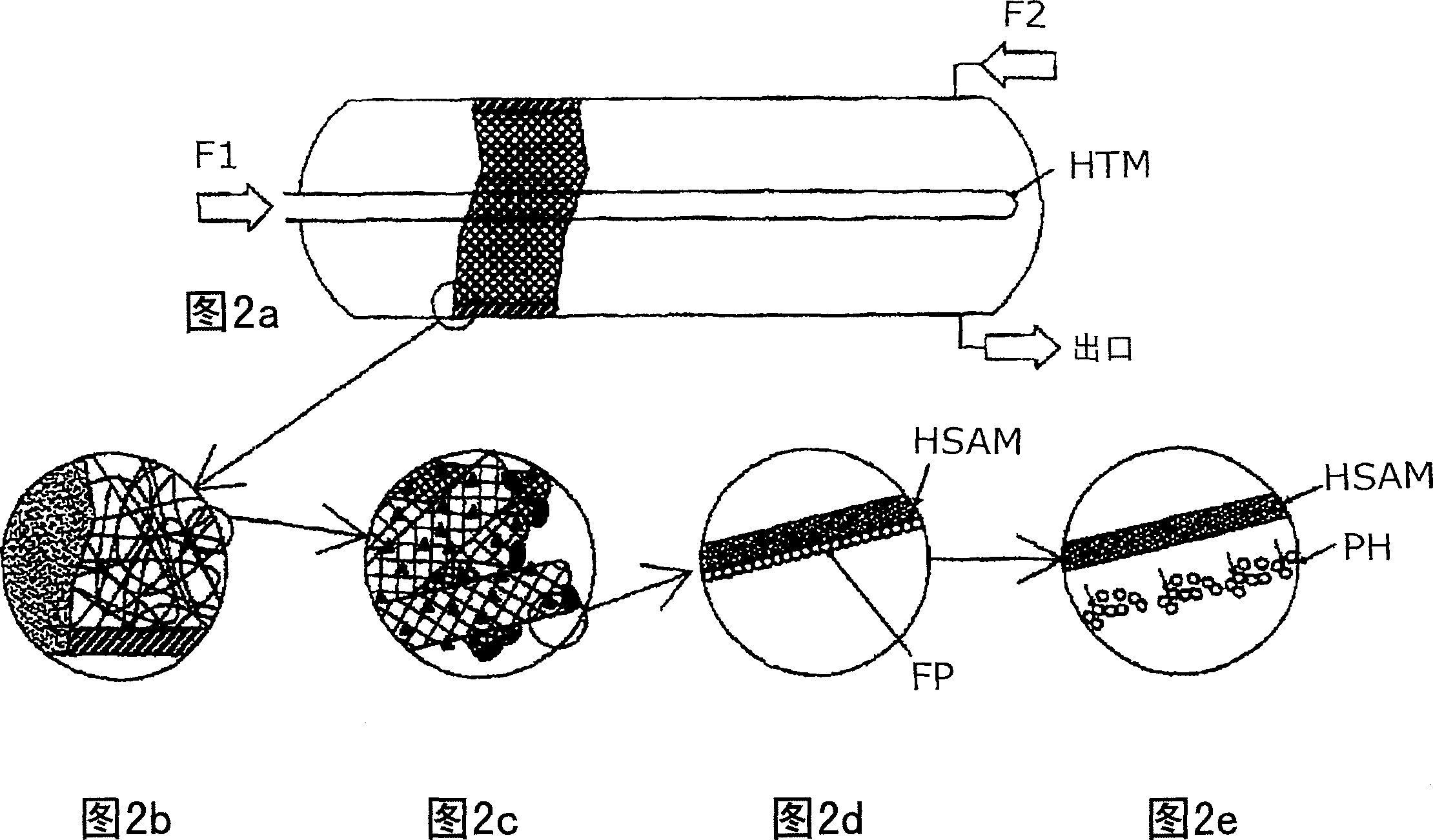

[0208] The reaction vessel may contain one or more zones of high surface area material. The material is preferably arranged in such a way that the reaction products produced can be easily cleaned and drained from the large surface area material. Without limitin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com