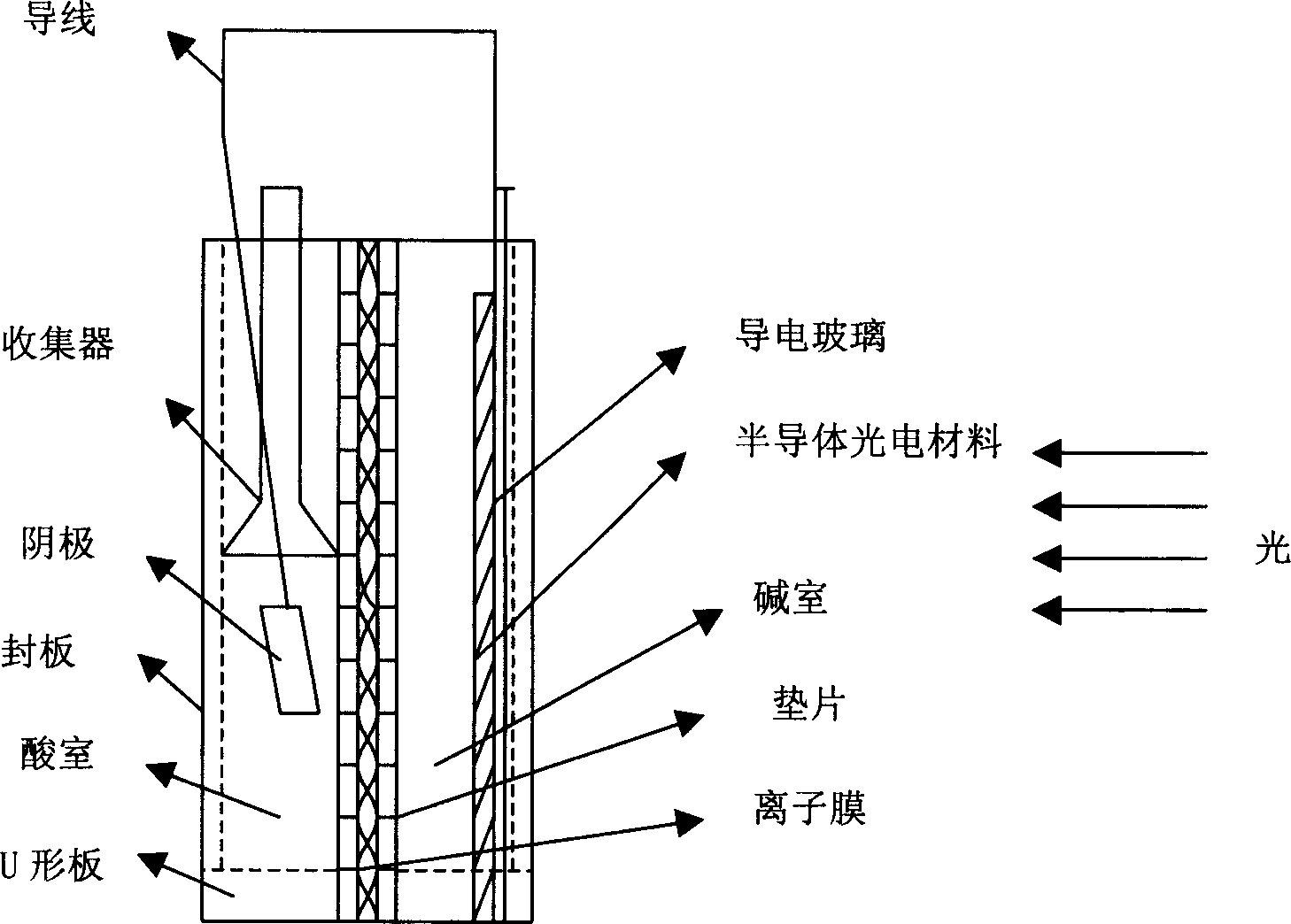

Ion diaphragm photoelectrolytic cell using solar energy directly decomposing water to make hydrogen

An ion diaphragm and photoelectrolysis technology, applied in the field of photoelectrochemistry, can solve the problems of increased electrolyte voltage drop, poor sealing, and unfavorable solution conduction, etc., and achieve the effect of simple equipment and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

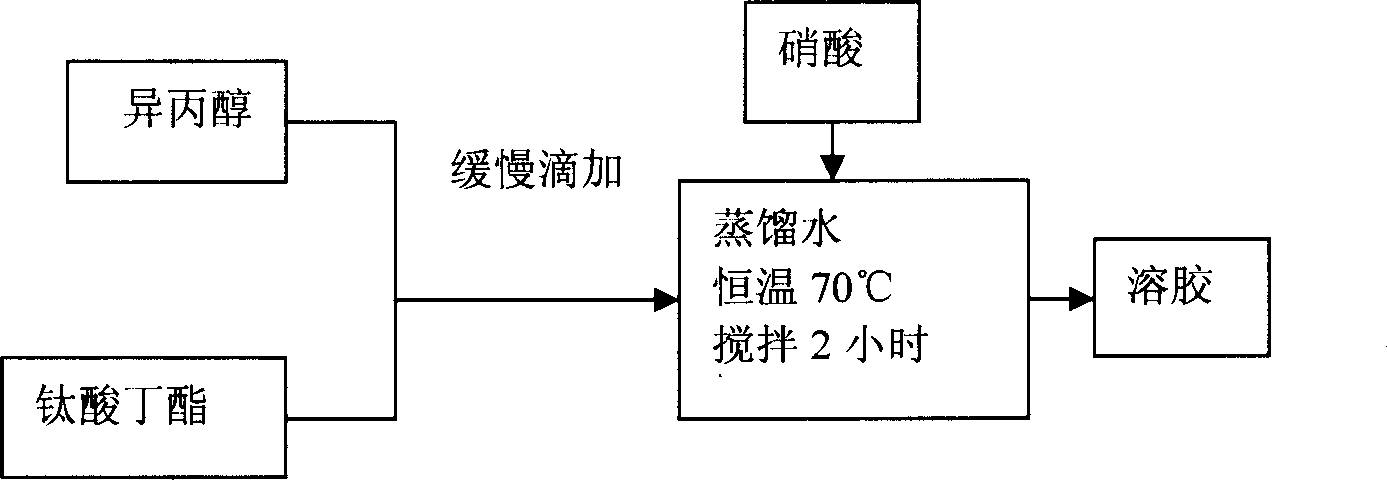

[0022] 1. The semiconductor photoanode material adopts TiO with light corrosion resistance and good chemical stability 2 . Using sol / gel+powder method to convert TiO 2 Fixed on conductive glass surface.

[0023] TiO 2 Sol preparation process: Add appropriate amount of concentrated nitric acid to distilled water, and heat to 70°C with a constant temperature water bath. Take a 1:3 isopropanol: butyl titanate solution and mix it evenly, then slowly add it dropwise into distilled water at constant temperature and stir, and continue to stir at constant temperature for 2 hours to obtain TiO-containing 2 27g / L TiO 2 Sol, sealed and stored. See attached for the process figure 1 .

[0024] TiO 2 Slurry preparation process: take appropriate amount of TiO 2 Sol, adding nano-TiO 2 powder (nano TiO 2 TiO in powder press slurry 2 The total amount is 120g / L (calculated to add), grinding and ultrasonic dispersion to obtain TiO 2 slurry.

[0025] TiO 2 Coating preparation proces...

Embodiment 2

[0035] Embodiment 2: The conditions are the same as in Embodiment 1, and the light source is the sunlight at noon in June in the urban area of Chengdu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com