Aluminum alloy pipe for high purity and high precision light sensitive drum base material and producing method

A manufacturing method and aluminum alloy technology, which are applied to aluminum alloy pipes for high-precision photosensitive drum base materials and manufacturing, high-purity fields, can solve problems such as difficulty in meeting requirements, and achieve the effect of ensuring purity and improving purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

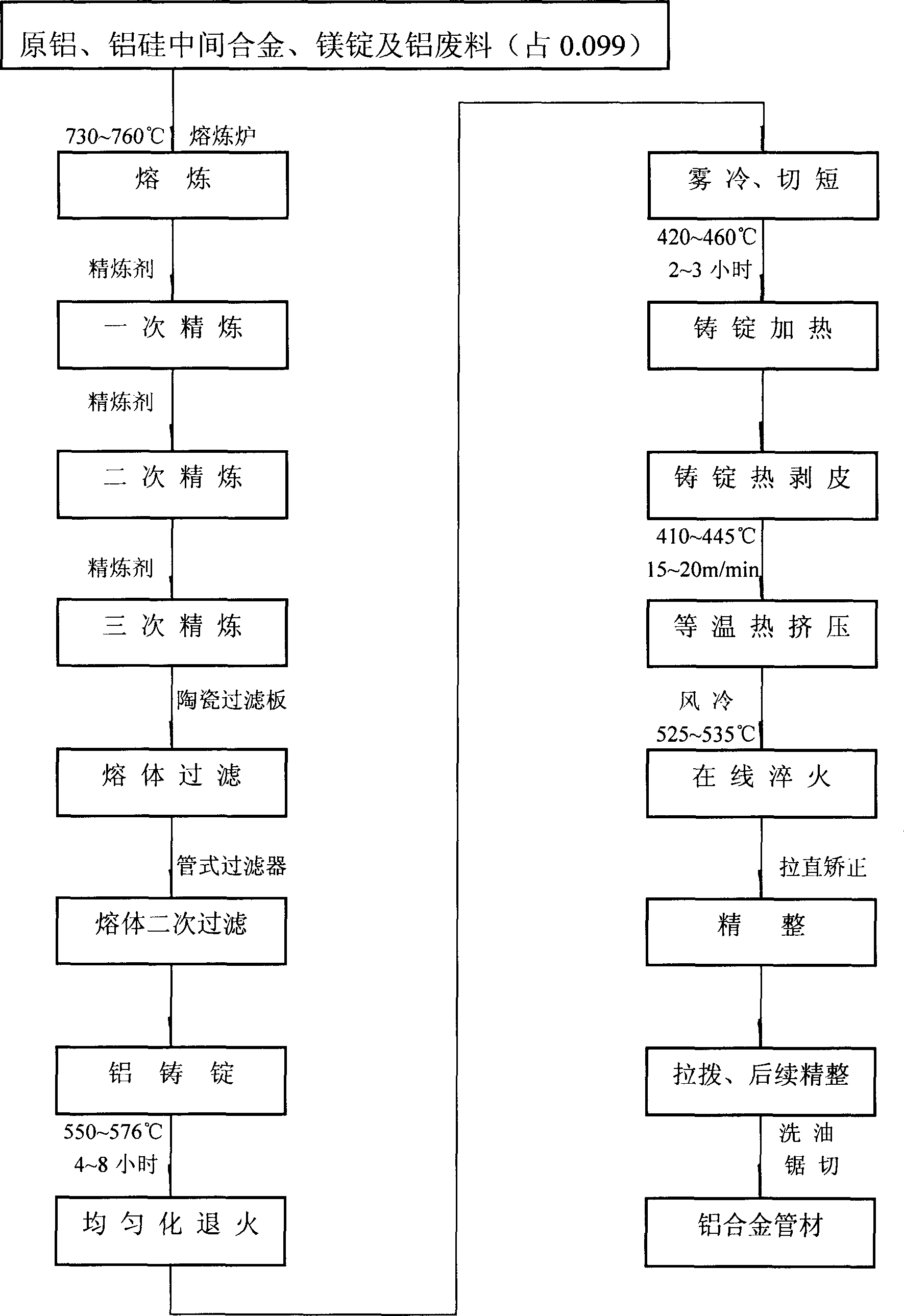

Method used

Image

Examples

Embodiment 1

[0044] First take 0.20 parts of silicon (silicon is added in the form of aluminum-silicon master alloy, Si content is about 11-12%), 0.46 parts of magnesium (magnesium is added in magnesium ingot, Mg content ≥ 99%), and the balance is aluminum (aluminum is Aluminum ingots are added, and the Al content is greater than or equal to 99.7%) for use.

[0045] It is then melted and refined.

[0046] Put aluminum and silicon into the melting furnace and heat it to 740-760°C, press magnesium into the aluminum melt with a magnesium cover to melt these raw materials, and then carry out the first refining in the melting furnace, add refining agent, remove The gas is argon, and the slag is removed after refining. Preheat the melt to above 800°C and transfer it to the holding furnace for the second refining, refining temperature: 740°C, refining time: 25Min, refining agent dosage: 1.5Kg / T, high-purity argon (content: ≥99.999% ) outgassing. Then carry out the third refining, and the refin...

Embodiment 2

[0065] First take 0.22 parts of silicon (silicon is added in the form of aluminum-silicon master alloy, and the Si content is about 11-12%), 0.50 parts of magnesium (magnesium is added in magnesium ingots, and the Mg content is ≥99%), and the balance is aluminum (aluminum is Aluminum ingots are added, and the Al content is greater than or equal to 99.7%) for use.

[0066] It is then melted and refined.

[0067] Put aluminum and silicon into the melting furnace and heat to 750-760°C, press magnesium into the aluminum melt with a magnesium cover to melt these raw materials, and then carry out the first refining in the melting furnace, add refining agent, remove The gas is argon, and the slag is removed after refining. Preheat the melt to above 800°C and transfer it to the holding furnace for the second refining, refining temperature: 740°C, refining time: 25Min, refining agent dosage: 2.0Kg / T, high-purity argon (content: ≥99.999% ) outgassing. Then carry out the third refinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com