Fluorescent material and its preparing method

A technology of fluorescent materials and light-emitting components, which is applied in the direction of light-emitting materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., and can solve problems such as difficult synthesis, narrow light-emitting spectrum, and difficult large-scale adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

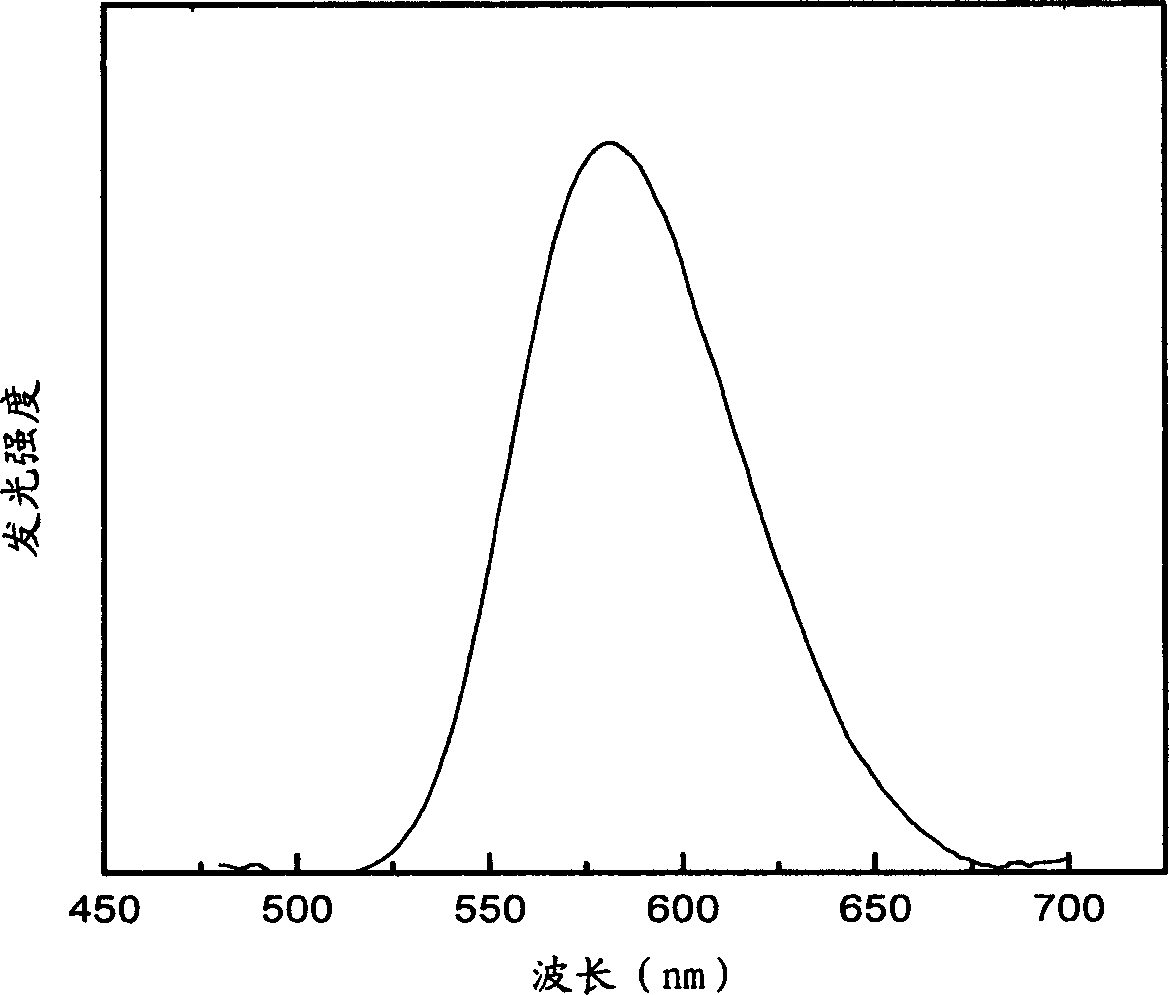

[0029] Mix the aqueous solution of strontium nitrate, barium nitrate, sodium nitrate, and europium nitrate with the alcohol solution of tetraethoxysilane, and adjust the molar ratio of strontium ions: barium ions: sodium ions: europium ions: silicon ions to be 2.82:0.08 : 0.05: 0.05: 1, make it evenly mixed, after heating and drying, the dry powder is calcined at 800°C for 3 hours. The calcined powder is then mixed with fluxing agent strontium chloride, the mixing molar ratio of strontium chloride and calcined powder is 0.1:1, and the molar ratio of strontium ion: barium ion: sodium ion: europium ion: silicon ion in the mixed powder is 2.92:0.08:0.05:0.05:1. Put the above mixed powder in reducing atmosphere (N 2 with H 2 Flow volume ratio is 95%: 5%) calcined at 1400 ° C for 4 hours, the chlorine component volatilizes at high temperature, and the europium ion is divalent after the reaction, and Sr 2.92 Ba 0.08 Na 0.05 Eu 0.05 SiO 5.075 Phosphor powder. The fluorescent ...

Embodiment 2

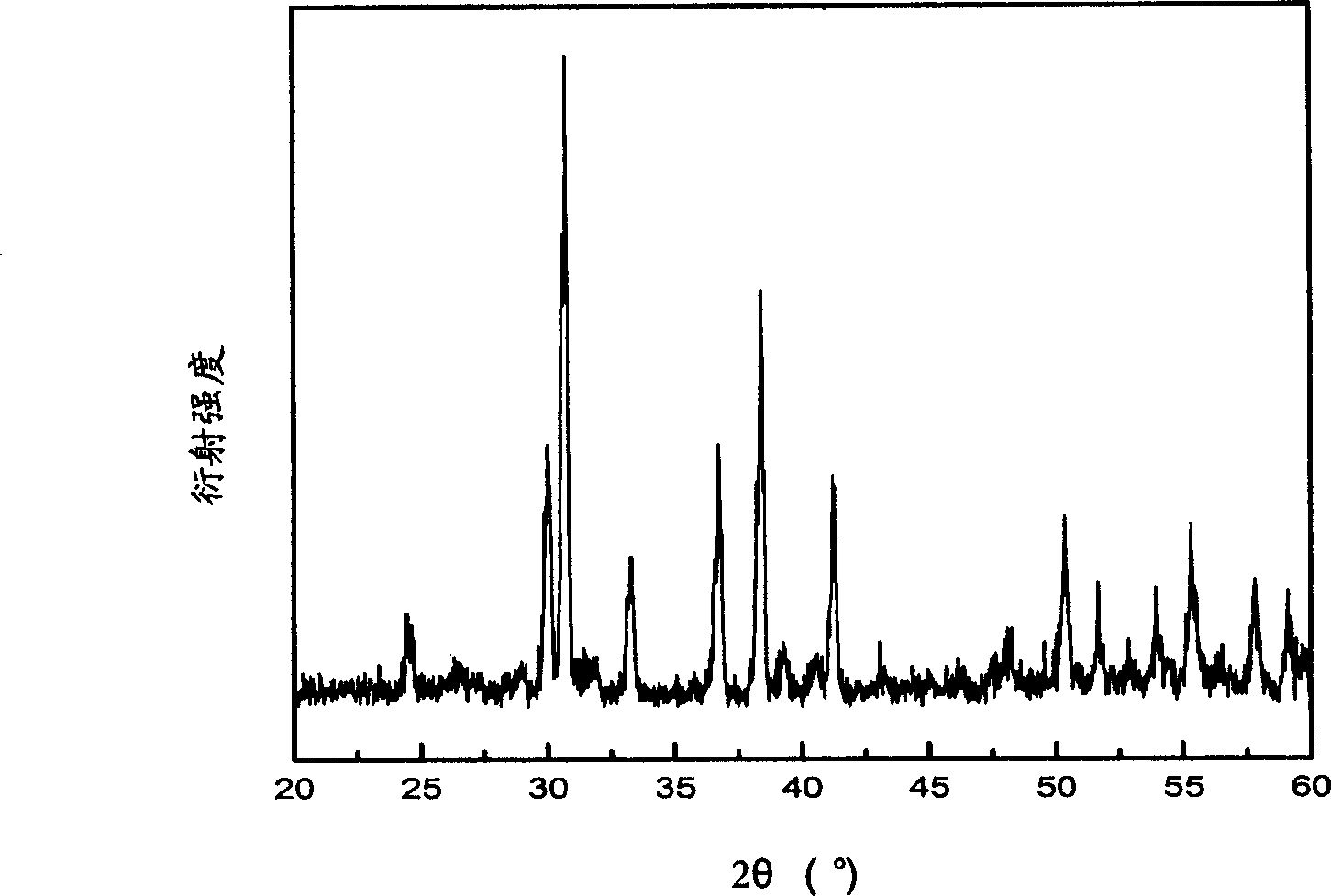

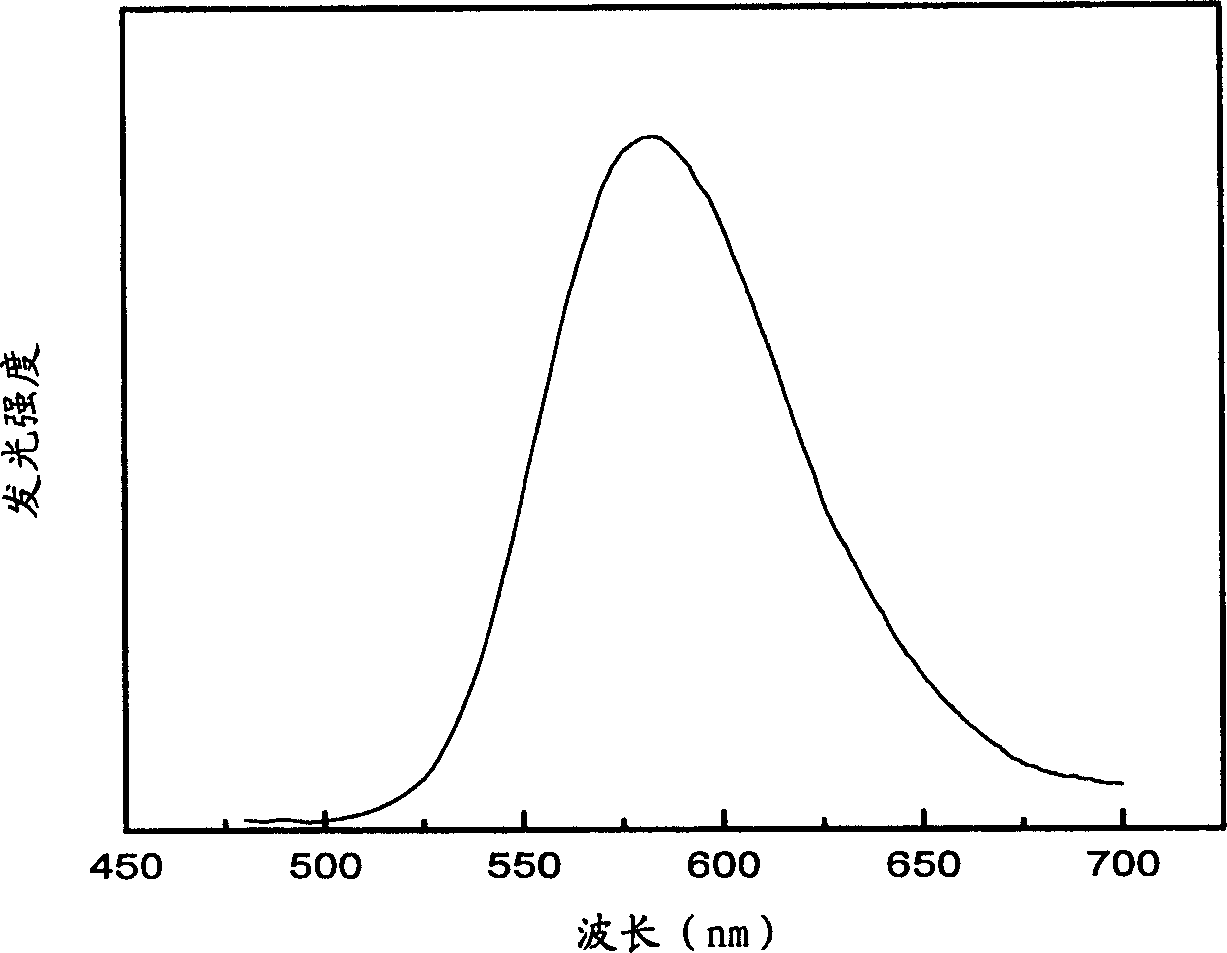

[0031] The aqueous solution of strontium nitrate, potassium nitrate and europium nitrate is mixed with the alcohol solution of tetraethoxysilane (tetraethoxysilane), and the molar ratio of strontium ions: potassium ions: europium ions: silicon ions is 2.54: 0.04: 0.42: 1, so that It is mixed evenly, and after heating and drying, the dry powder is calcined at 900°C for 2 hours. The calcined powder is then mixed with fluxing agent strontium chloride, the mixing molar ratio of strontium chloride and calcined powder is 0.3:1, and the molar ratio of strontium ion: potassium ion: europium ion: silicon ion in the mixed powder is 2.84:0.04 :0.42:1. Put the above mixed powder in reducing atmosphere (N 2 with H 2 Flow volume ratio is 95%: 5%) calcined at 1400 ° C for 4 hours, the chlorine component volatilizes at high temperature, and the europium ion is divalent after the reaction, and Sr 2.84 K 0.04 Eu 0.42 SiO 5.28 Phosphor powder. The fluorescent material is analyzed by X-ray...

Embodiment 3

[0033] Mix the aqueous solution of strontium nitrate, magnesium nitrate, potassium nitrate, bismuth nitrate, and europium nitrate with the alcohol solution of tetraethoxysilane to control strontium ions: magnesium ions: potassium ions: bismuth ions: europium ions: silicon ions The molar ratio is 2.58:0.08:0.07:0.07:0.2:1, so that they are mixed uniformly, and after heating and drying, the dry powder is calcined at 880°C for 4 hours. The calcined powder is then mixed with flux ammonium chloride, the mixing molar ratio of ammonium chloride and calcined powder is 0.1:1, strontium ion: magnesium ion: potassium ion: bismuth ion: europium ion: silicon ion in the mixed powder The molar ratio is 2.58:0.08:0.07:0.07:0.2:1. Put the above mixed powder in reducing atmosphere (N 2 with H 2 Flow volume ratio is 95%: 5%) calcined at 1450 ° C for 3 hours, the chlorine component volatilizes at high temperature, and the europium ion is divalent after the reaction, and Sr 2.58 Mg 0.08 K 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com