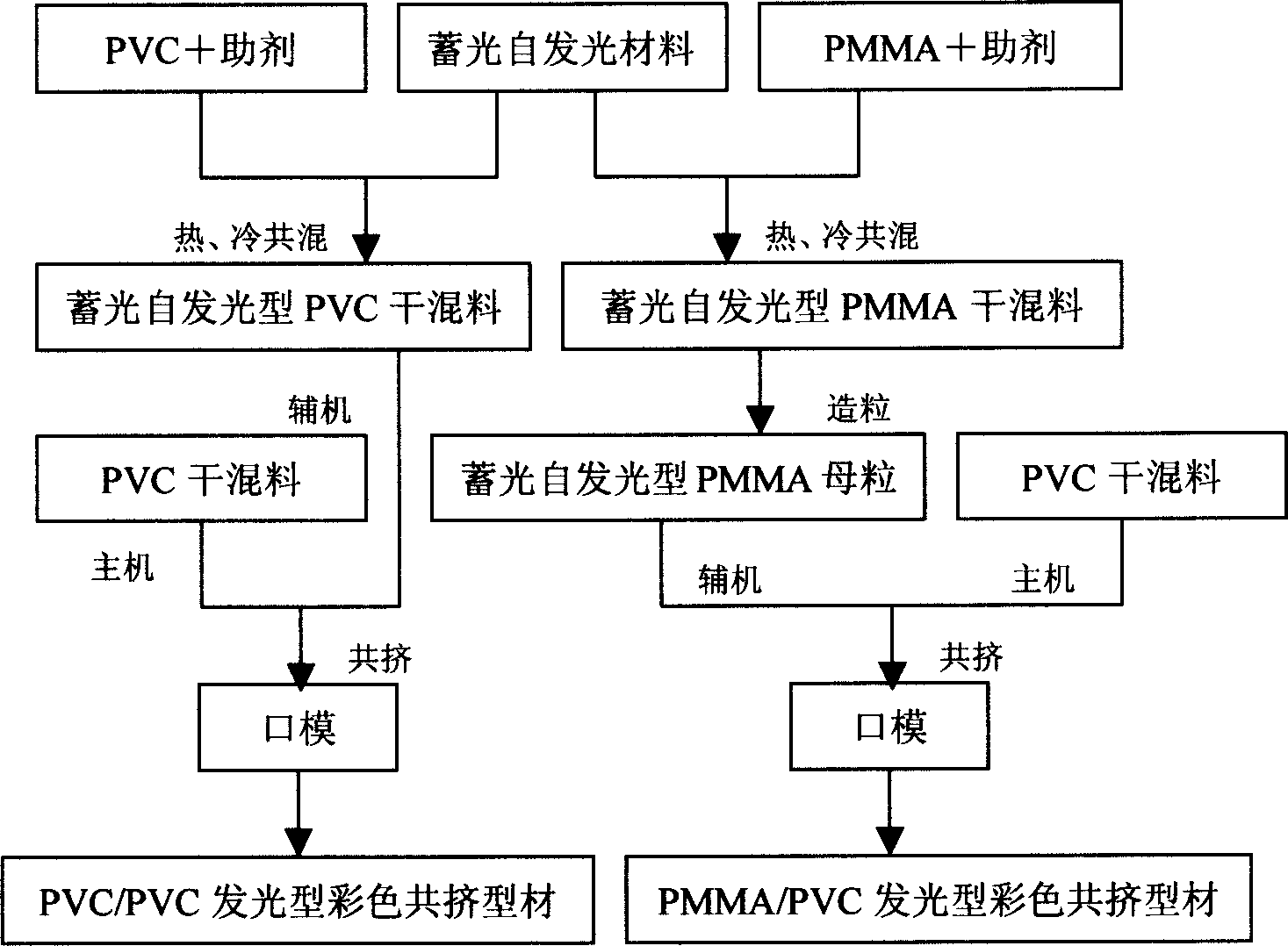

Coextruded light storage type self luminous plastic irregular profile and its production method

A light-storage type self-illumination and raw material technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of poor adhesion, falling off, poor profile stability, etc., and achieve the effects of improving weather resistance, saving costs, and not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] PMMA / PVC single-sided co-extruded casement window profiles:

[0023] raw material name

Mass ratio (%)

Light-storing self-luminous material

Modified PMMA Plastic Masterbatch

35

65

[0024] raw material name

proportional share

pvc

stabilizer

modifier

Colorant

filler

Processing aids

paint

100

6

9

5

8

1

0.03

[0025] Among them: lead stabilizers or calcium / zinc stabilizers for stabilizers; acrylates for modifiers; titanium dioxide for colorants; calcium carbonate or wollastonite for fillers; acrylates for processing aids; ultramarine blue for pigments.

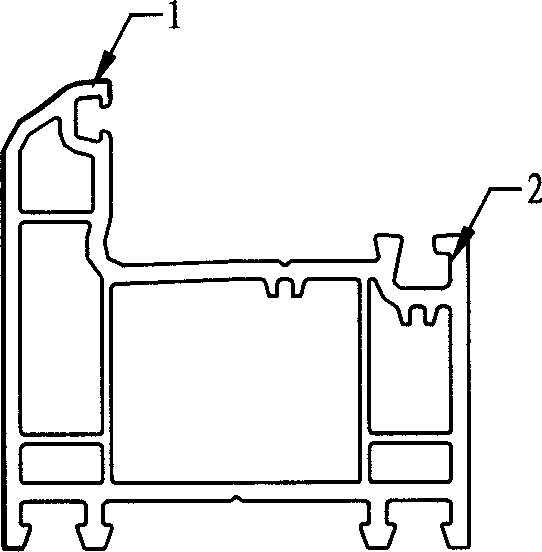

[0026] Profile model: BR60A-1, FR70A-1, SE72A-1, the sections are as follows Figure three , Four , five shown.

example 2

[0027] Example 2. PVC / PVC single-sided co-extruded side-hung door profiles:

[0028] raw material name

Mass ratio (%)

Light-storing self-luminous material

PVC substrate

5

95

[0029] raw material name

proportional share

pvc

stabilizer

modifier

Colorant

filler

Processing aids

paint

100

4

12

7

8

3

0.02

[0030] Among them: lead stabilizer or calcium / zinc stabilizer for stabilizer; CPE modifier for modifier; titanium dioxide for colorant; talcum powder or kaolin for filler; acrylate for processing aid; ultramarine blue for pigment.

[0031] Profile model: MK60A-1, FR104A-1, SE86A-1, the sections are as follows Figure six , seven , as shown in eight.

example 3

[0032] Example 3, PMMA / PVC single-sided co-extrusion sliding window profile:

[0033] raw material name

Mass ratio (%)

Contains 20% light storage type self-luminous material

PMMA Plastic Masterbatch

Modified PMMA Plastic Masterbatch

50

50

[0034] raw material name

proportional share

pvc

stabilizer

modifier

Colorant

filler

Processing aids

paint

100

2

5

8

7

2

0.04

[0035] Among them: organotin stabilizers for stabilizers; acrylate modifiers for modifiers; titanium dioxide for colorants; calcium carbonate or talcum powder for fillers; acrylates for processing aids; phthalocyanine blue for pigments.

[0036] Profile model: HF88A-1, SF66A-1, the sections are as follows Figure 9 , ten shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com