Positive PS-process photosensitive coating liquid for high-speed vehicle coating

A technology of coating liquid and high speed, which is applied in photosensitive materials used in optomechanical equipment, photoplate making process of patterned surface, optics, etc., can solve the problems of high cost and impact, and achieve the effect of uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

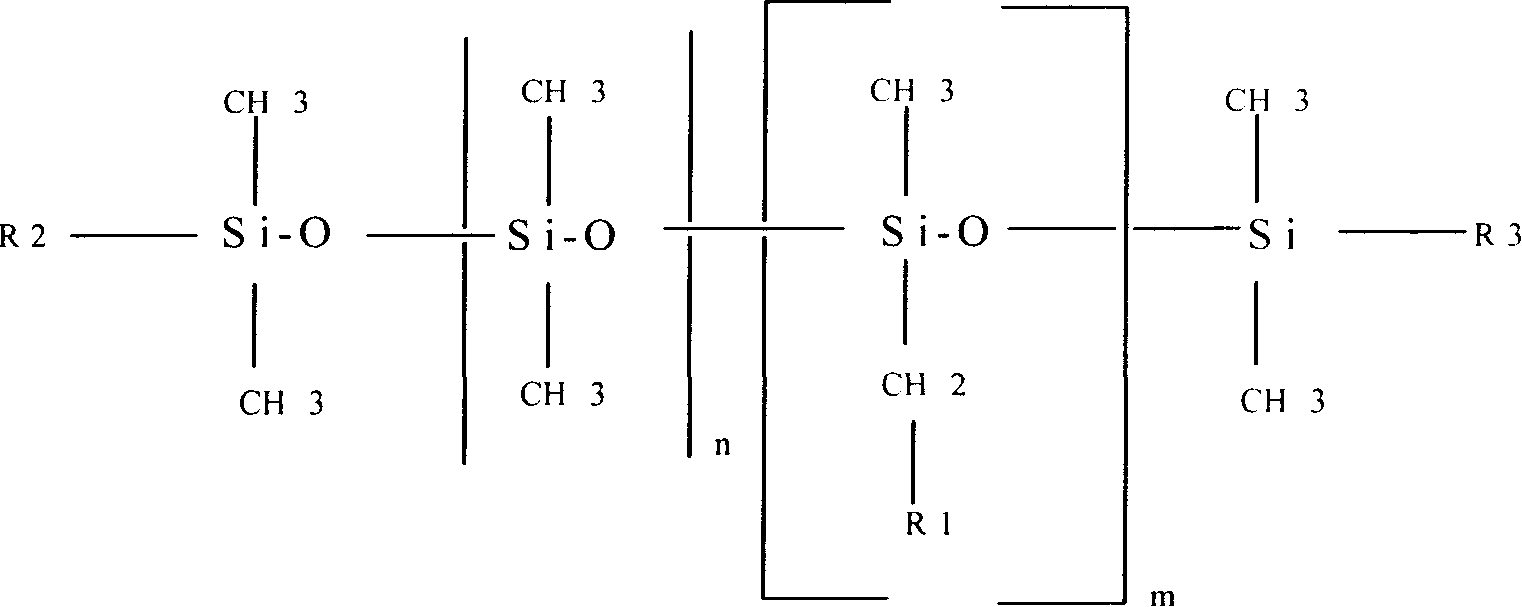

Method used

Image

Examples

Embodiment 1

[0030] Prepare the coating liquid with the following components, filter it through a 0.1μm wire core, and then coat it on an automatic reel production line at a speed of 40 m / min to make a PS plate.

[0031] Novolac resin ST-1071 4.0 parts

[0032] Photosensitive resin P-3000 1.8 parts

[0033] Oil-soluble blue dye BO-603 0.096 parts

[0034] Color-changing dye TB 0.024 parts

[0035] Ethylene glycol monoethyl ether 34.0 parts

[0036] Compound I (m=18, n=8, a=6, b=6) 0.08 parts

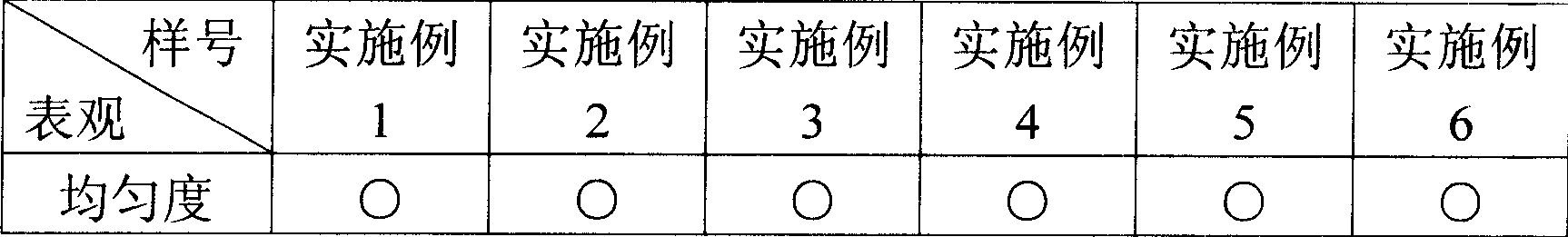

[0037] Observing the appearance under a 40W yellow safe light, the uniformity is divided into three grades: ○------good, △------good, X-------poor. The results are shown in Table 1

Embodiment 2

[0039] Identical with the preparation method of embodiment 1, just formula component takes place following change:

[0040] Novolac resin ST-1071 3.06 parts

[0041] m-cresol resin 0.34 parts

[0042] Photosensitive resin P-3000 1.32 parts

[0043] Oil-soluble blue dye BO-603 0.075 parts

[0044] Color-changing dye TB 0.025 parts

[0045] Ethylene glycol monoethyl ether 35.2 parts

[0046] Compound I (m=18, n=8, a=6, b=6) 0.06 parts

[0047] The appearance was observed under a 40W yellow safe light, and the results are listed in Table 1.

Embodiment 3

[0049] Identical with the preparation method of embodiment 1, just formula component takes place following change:

[0050] Novolac resin ST-1071 2.88 parts

[0051] Photosensitive resin P-3000 0.7 parts

[0052] 214 grafted phenolic resin photosensitive resin 0.3 parts

[0053](graft rate 30%)

[0054] Oil-soluble blue dye BO-603 0.06 parts

[0055] Color-changing dye TB 0.02 parts

[0056] Propylene glycol monomethyl ether 36.0 parts

[0057] Compound I (m=10, n=6, a=8, b=4) 0.04 part

[0058] The appearance was observed under a 40W yellow safe light, and the results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com