Method for preparing stainless steel decorative plate and pattern by vibration grinding

A stainless steel and decorative plate technology, applied in grinding/polishing equipment, grinders, belt grinders, etc., can solve the problems of different textures, difficult to match texture texture, difficult to control texture grinding quality, etc., to achieve clear texture and surface. Uniform, over-smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

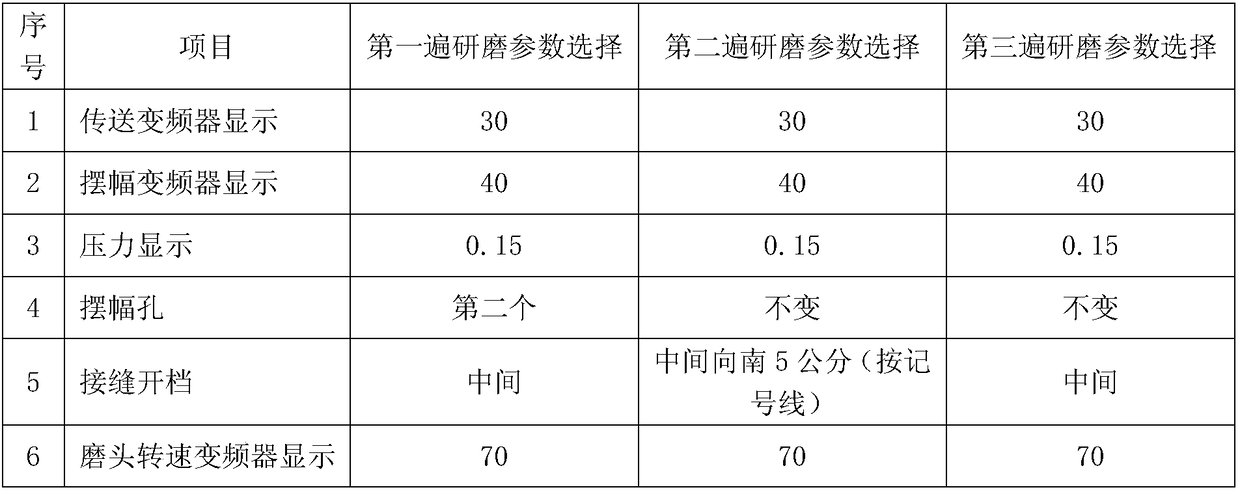

[0011] The method of vibrating grinding to prepare stainless steel decorative plates and patterns, the control of grinding wheel reduction; 6 cylinders are used to press the grinding wheel at the same time, and the distributor summarizes the pressure adjustment method to ensure that the reduction is at 0.15MPA, ensuring that there is no trace on the surface of the pattern plate. Chromatic aberration; worm gear motor reducer direct connection mode, stable transmission requirements, frequency conversion control. Selection of sand grains of the abrasive belt and selection of mesh size;

[0012] Transmission method: The worm gear motor reducer is directly connected to the grinding wheel. The grinding wheel is installed at the bottom of the worm gear motor reducer. The transmission requirements are stable. The speed of the grinding wheel is controlled by frequency conversion at 100-200 rpm; the grinding wheel reduction is controlled. : Use 4-12 side-by-side cylinders to control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com