Silicone adhesive agent

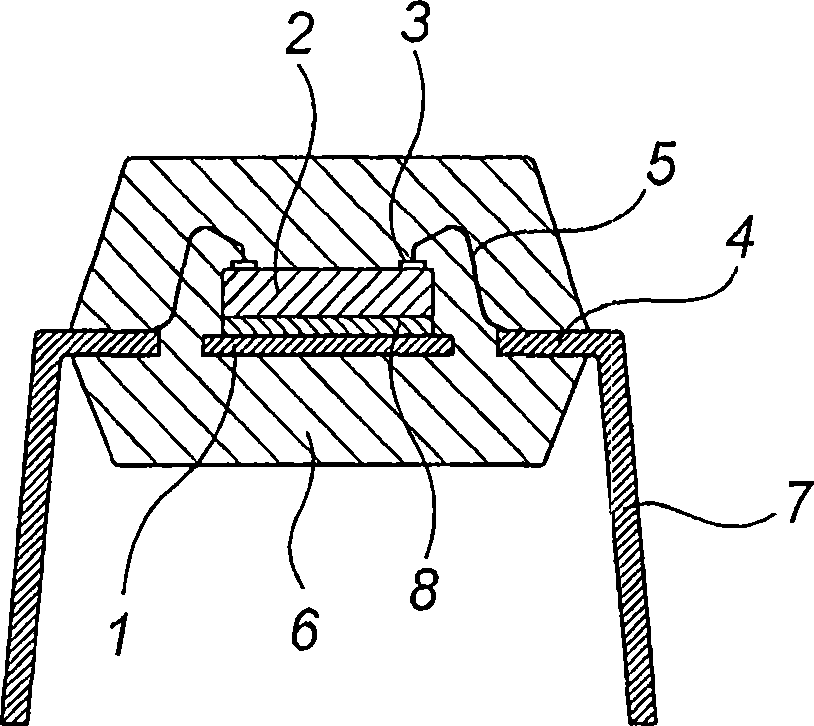

An adhesive, siloxane technology, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of reduced bonding between semiconductor chips and bonding wires or lead frames and bonding wires Reduced device reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

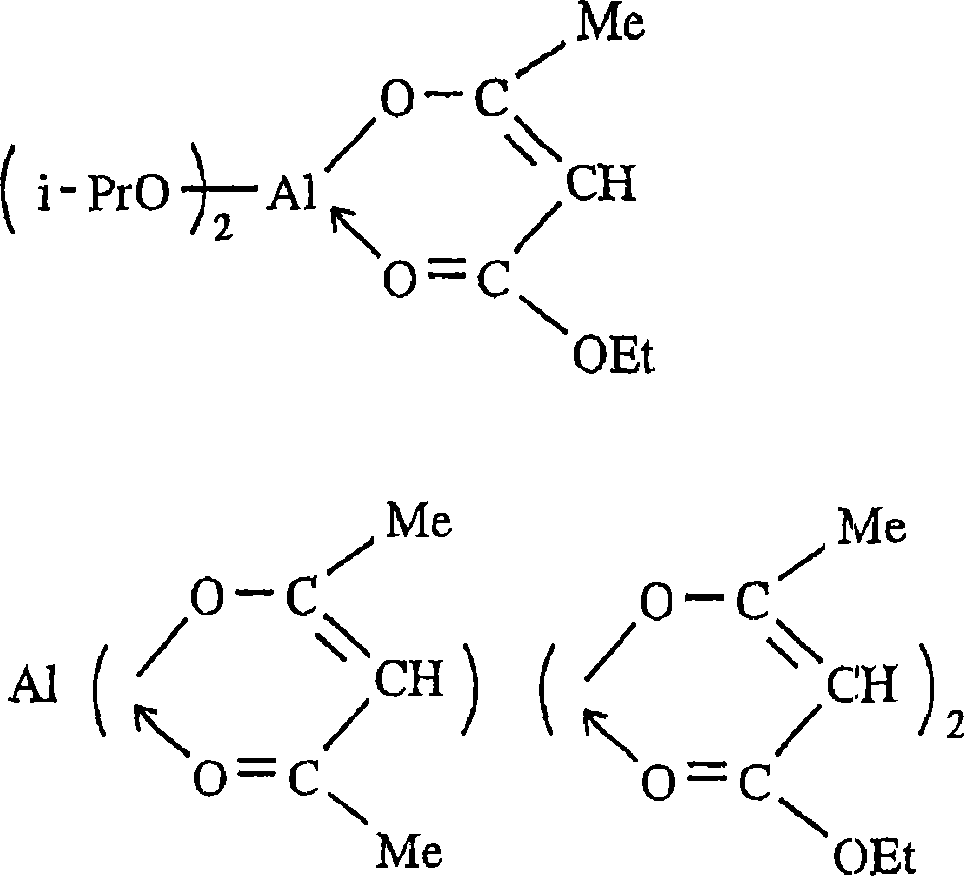

[0011] Hereinafter, the present invention will be described in detail. The present invention is a silicone adhesive for bonding a semiconductor chip and a mounting member of the chip, characterized in that it contains an additive that contaminates a glass plate during heat curing so that the contact angle on the glass plate is 70° or less A reaction-curable silicone rubber composition, and examples of such an addition reaction-curable silicone rubber composition include:

[0012] Addition reaction-curable silicone rubber composition (hereinafter referred to as composition 1 of the present invention) comprising:

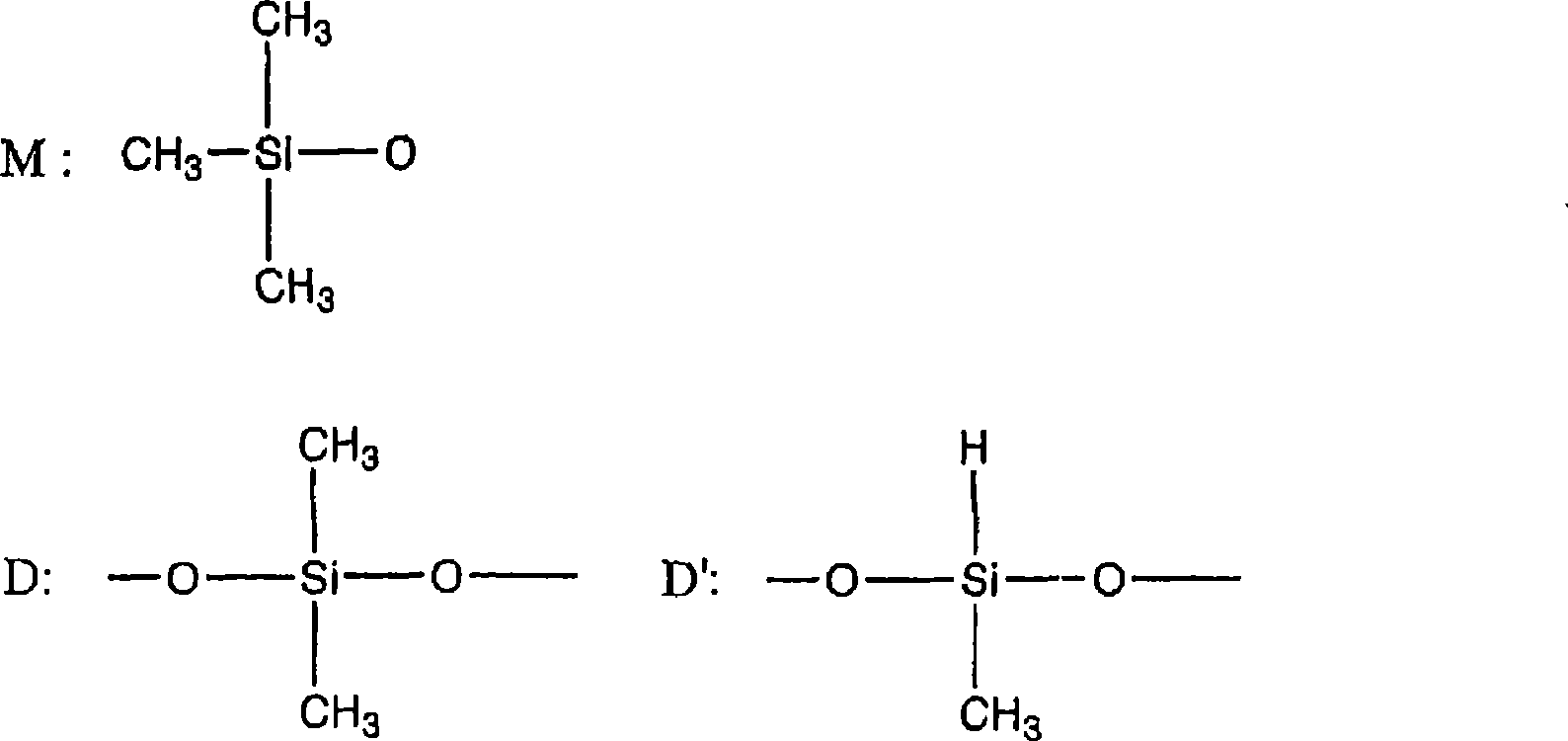

[0013] (A) polyorganosiloxane having 2 or more silicon atom-bonded alkenyl groups in 1 molecule, 100 parts by weight;

[0014] (B) Polyorganosiloxane having a heating loss of 5% by weight or less at 100°C x 1 hour and having two or more silicon-bonded hydrogen atoms in one molecule, for one chain of component (A) The alkenyl group is sufficient to provide 0.5 to 3 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com