Single-side glue spraying device for PE film and using method of single-side glue spraying device

A spraying device and single-sided technology, which is applied to the device for coating liquid on the surface, coating and other directions, can solve the problems of waste, edge lifting, uneven painting, etc., and achieve reduced flow everywhere, strong spraying force, and adhesion effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

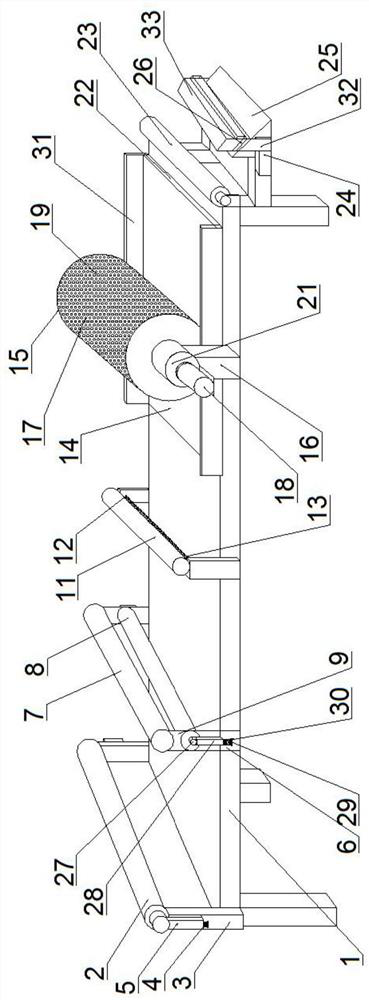

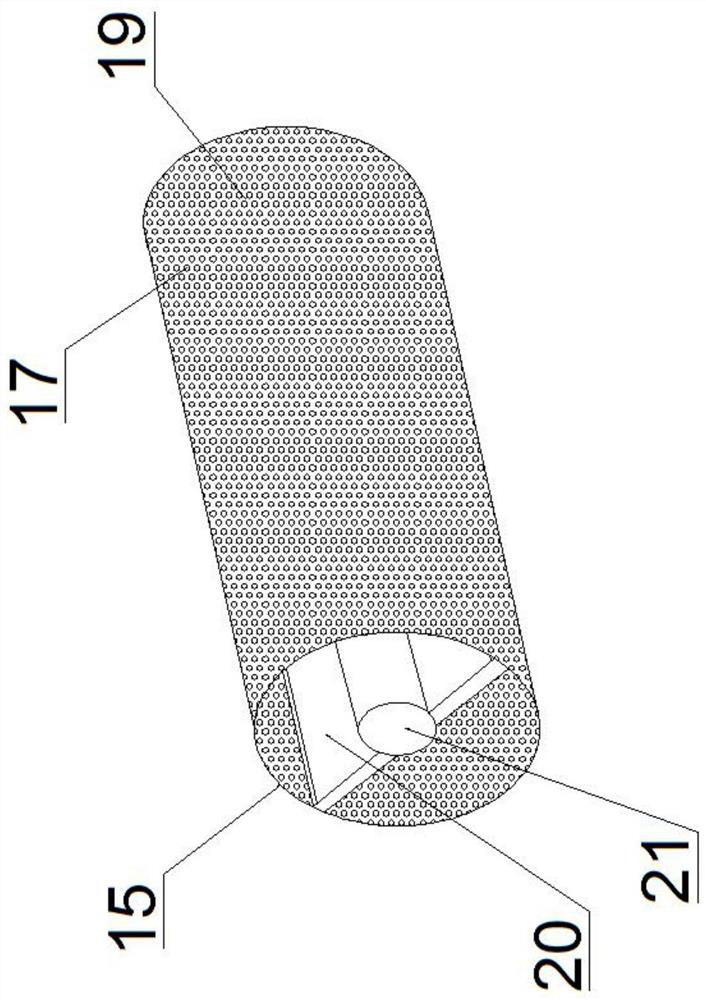

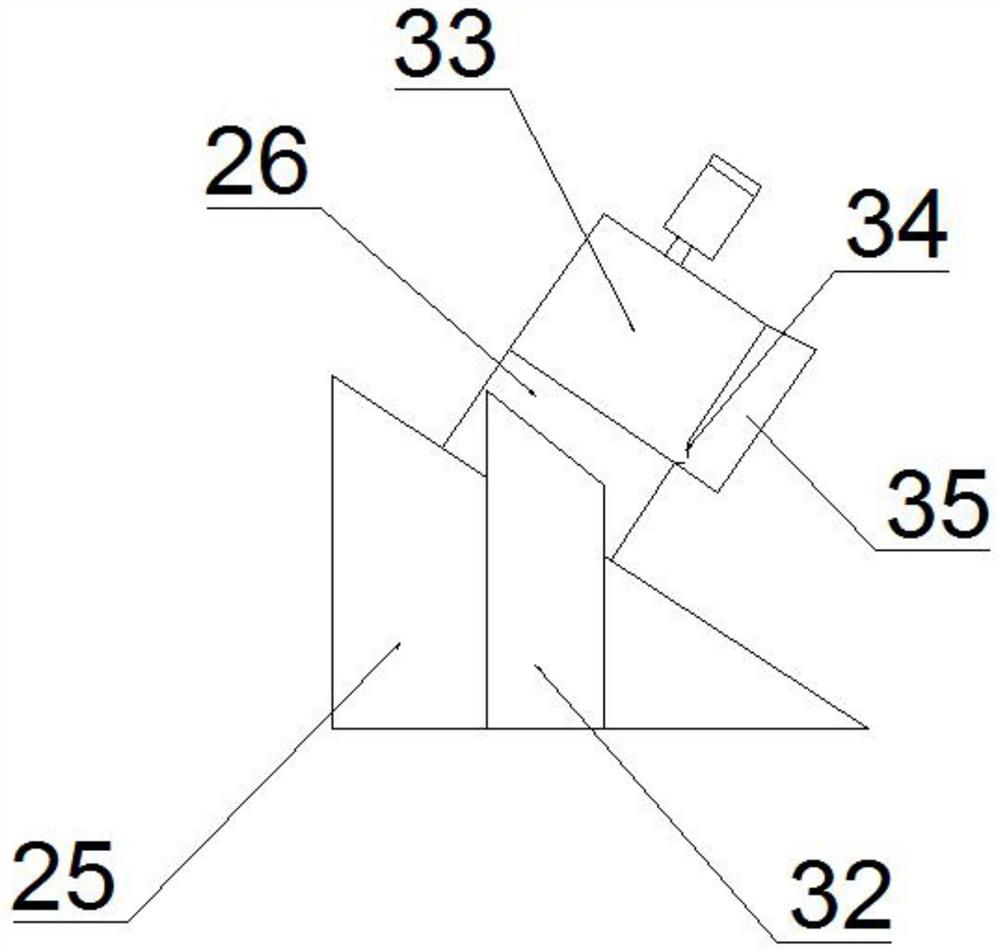

[0027] Such as figure 1As shown, a single-sided glue spraying device for PE film includes a device base 1, a tension roller 2 is installed on the left side of the device base 1, and the tension roller 2 is installed on the device through a tension bracket 3 Above the device base 1, the tensioning bracket 3 includes a tensioning screw 4, the tensioning screw 4 is installed on one side of the tensioning bracket 3, the upper end of the tensioning screw 4 is equipped with a roller seat 5, and the roller seat 5 The tension roller 2 is installed on the upper end, the roller seat 5 is slidingly connected with the tension bracket 3, and the leveling device 6 is installed on the right side of the tension roller 2, and the leveling device 6 includes a first roller 7 and the second roller 8, the first roller 7 is installed on the upper end of the leveling support 9, the second roller 8 is installed on the leveling support 9 below the first roller 7, and the leveling device 6 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com