Process and apparatus for preparing metal nitride catalyst material

A technology of catalytic materials and special equipment, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large axial and radial temperature gradients, difficult control of bed temperature, and bed temperature distribution. Uneven problems, to achieve the effect of simplified operation, low cost, and 100% utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention is based on γ-Mo 2 The preparation technology of N is described in detail.

[0029] In view of the preparation of high specific surface area γ-Mo 2 The research experience of N, the present invention adopts the approach of temperature-programmed gradual reaction, utilizes N 2 Reduction of MoO as a reducing gas 3 . By controlling the heating rate and increasing the gas flow rate, the accumulation of product moisture is prevented; in order to reduce gas consumption, a gas circulation device is designed in the system to reduce production costs.

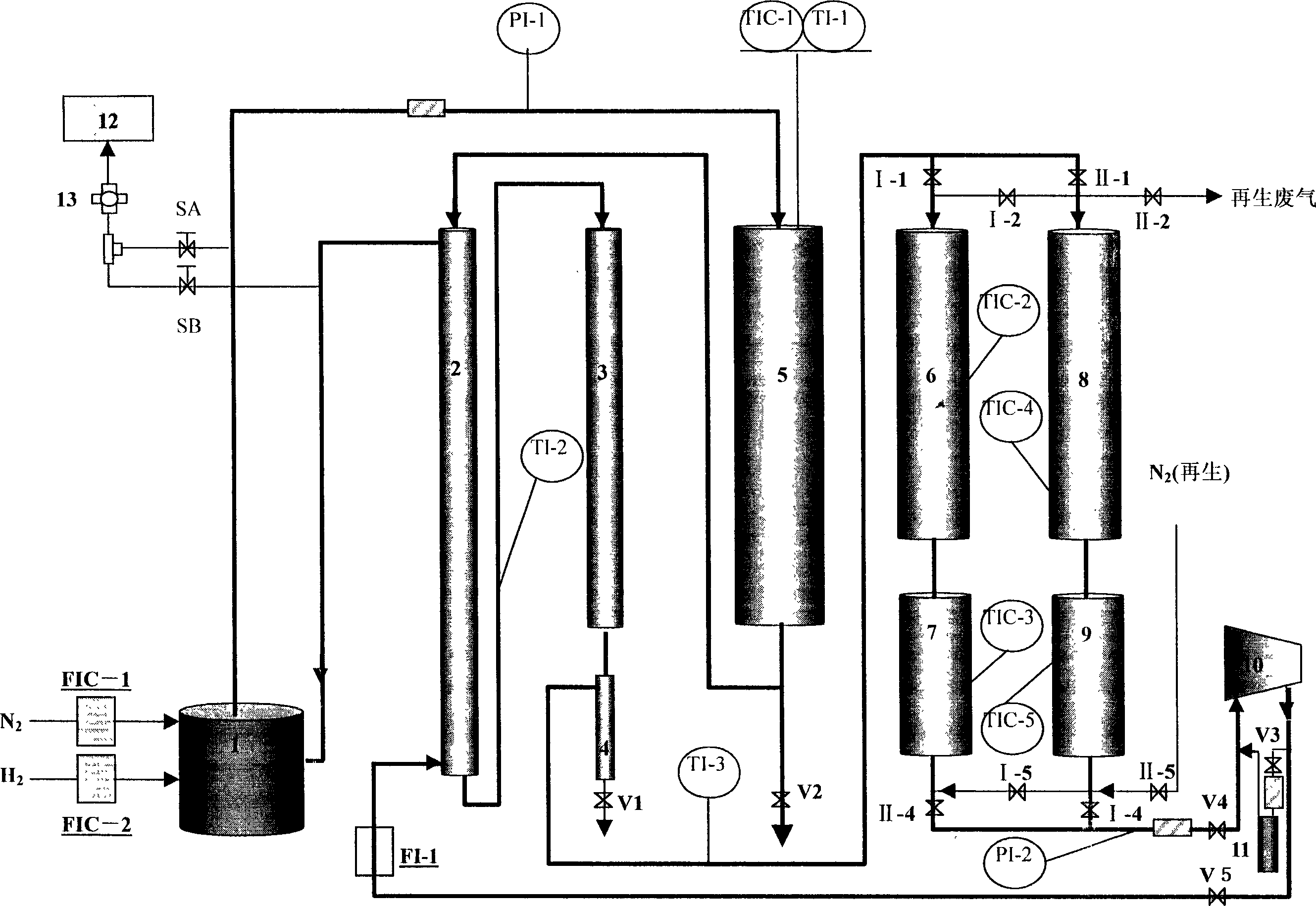

[0030] Batch molybdenum nitride reaction device such as figure 1 shown.

[0031] 1. Gas

[0032] 1 Nitrogen - high-purity nitrogen (99.999% concentration), nitriding raw material, from steel cylinders, to the mixer;

[0033] 2 Hydrogen - high-purity hydrogen (concentration 99.999%), nitriding raw material, from the cylinder, to the mixer;

[0034] 3 Mixed gas——Mixed by nitrogen, hydrogen, and circulat...

Embodiment 1

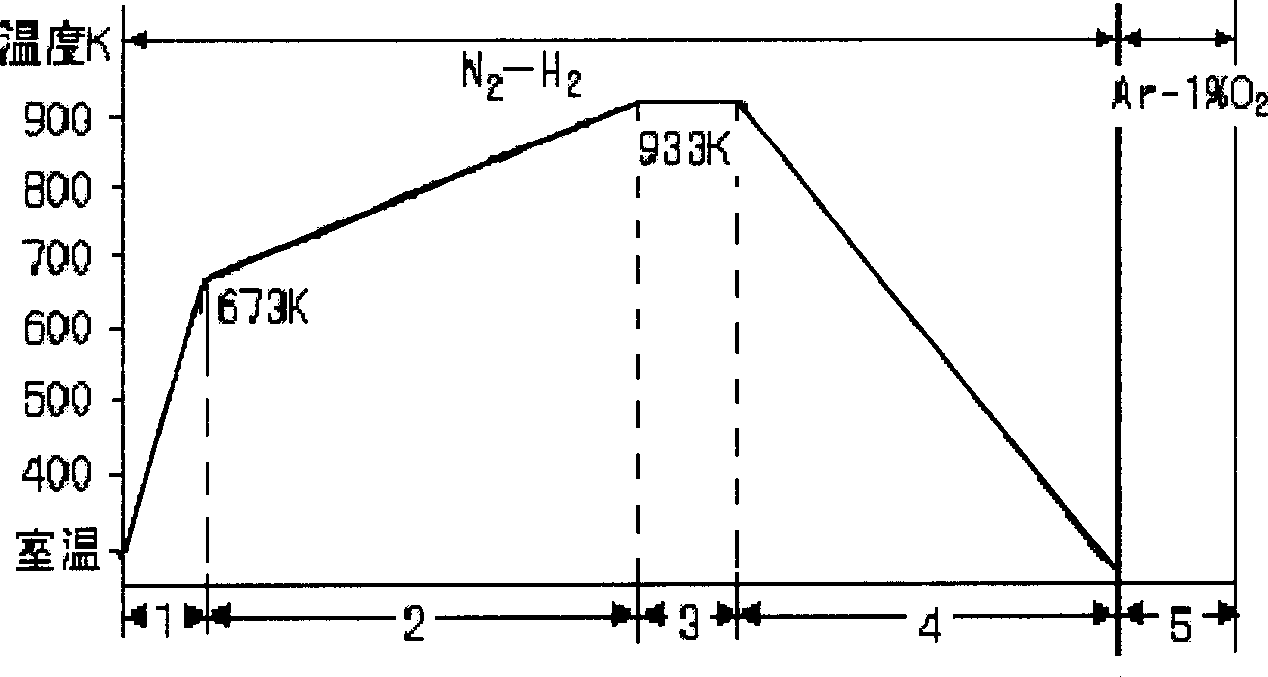

[0154] The temperature programming system that the present invention adopts is as figure 2 As shown, the optimal temperature programming regime is:

Embodiment 25

[0155] 1. Rapid heating from room temperature to 673K, the heating rate is 1-50K / min (25K / min in this embodiment);

[0156] 2.673-933K adopts 0.6-1K / min (this embodiment 0.6K / min) speed to heat up;

[0157] 3. 933K constant temperature 0.5-1hr (this embodiment 1hr);

[0158] 4. Cool to room temperature in the reactor;

[0159] 5. Switch N at room temperature 2 -H 2 The mixed gas is 99%Ar-1%O by volume 2 Mixed gas (ie passivation treatment) 12-24hr, 24hr in this embodiment.

[0160] γ-Mo of the present invention 2 The N-supported catalyst was prepared as follows:

[0161] According to the above process, the MoO 3 / TiO 2 、MoO 3 / NiO-TiO 2 、MoO 3 / Al 2 o 3 -TiO 2 or MoO 3 / Al 2 o 3 Put into the reactor of the present invention, carry out N 2 -H 2 Reductive replacement of MoO 3 reaction to produce Mo 2 N / TiO 2 、Mo 2 N / NiO-TiO 2 、Mo 2 N / Al 2 o 3 -TiO 2 or Mo 2 N / Al 2 o 3 Supported metal nitride catalyst. N 2 -H 2 Volume ratio of mixed gas: H 2 / N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com