Grain transporter

A technology of conveyors and belt conveyors, which is applied in the direction of conveyor objects, transportation and packaging, solid separation, etc., can solve the problems of polluting the environment, impurities falling everywhere, poor impurity removal effect, etc., and achieve the effect of reducing pollution and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

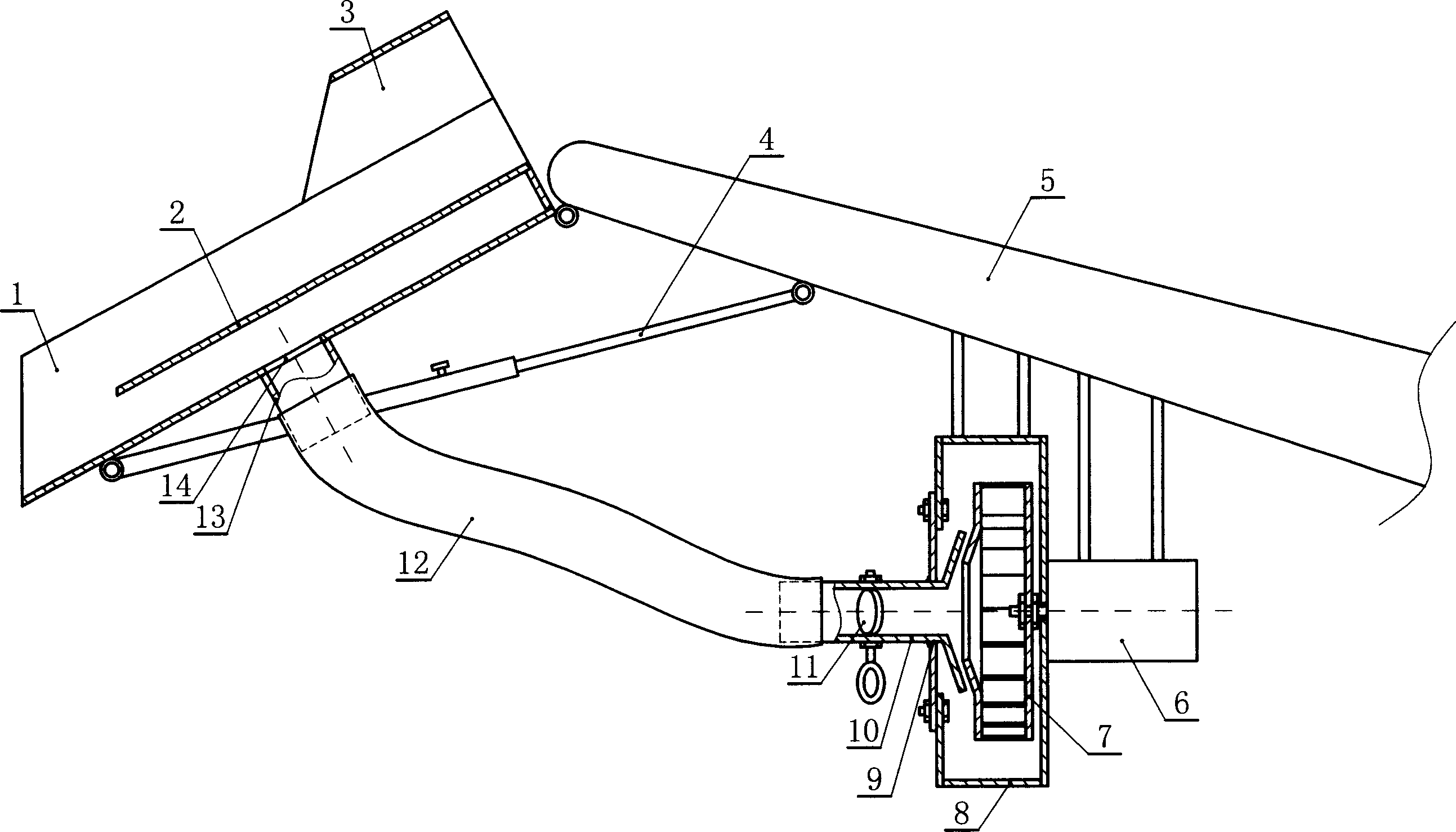

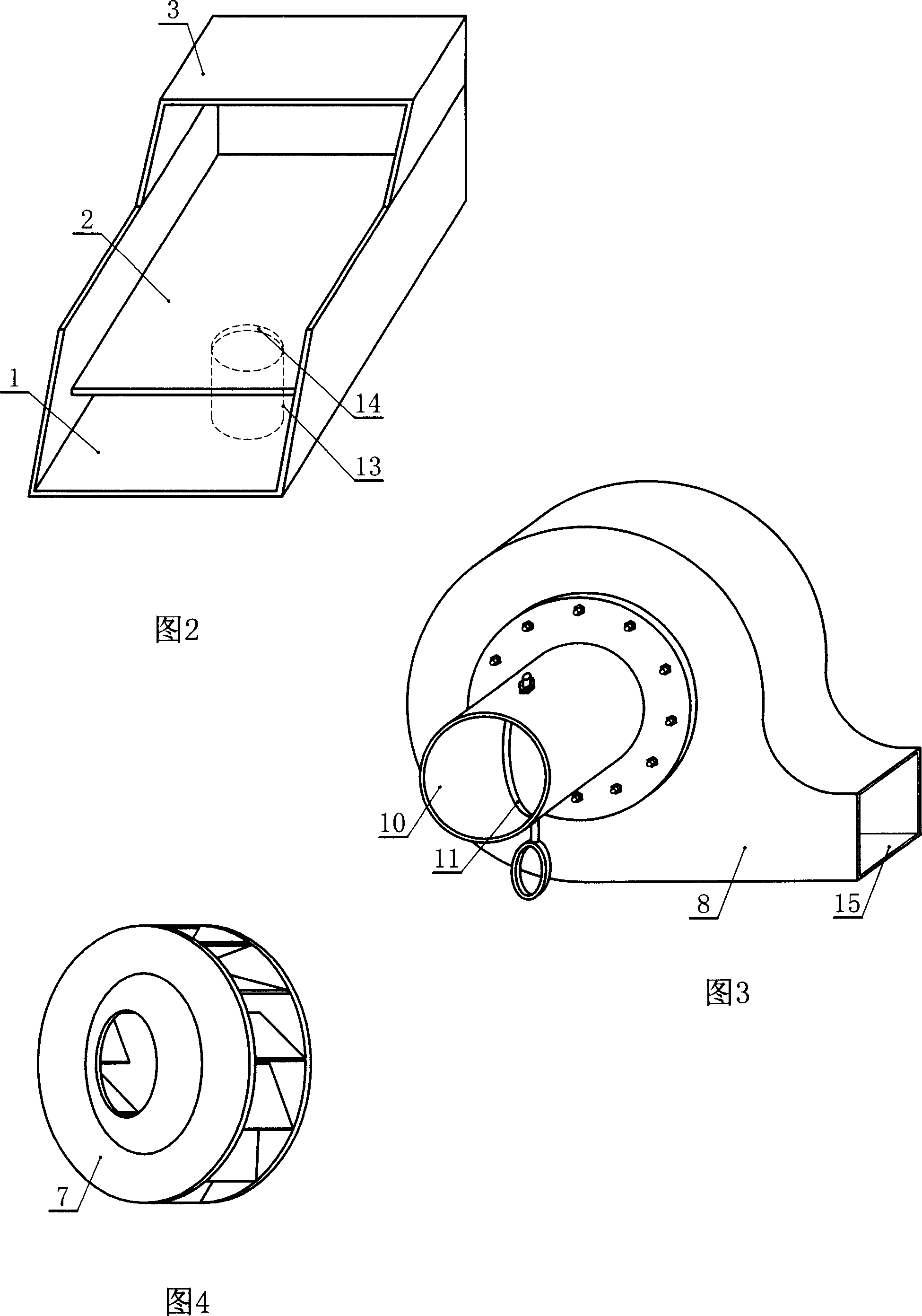

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment: a kind of grain conveyor, such as figure 1 , 2, 3, and 4, which include a belt conveyor frame 5, the front end of the belt conveyor frame 5 is fixedly equipped with a suction hopper 1, and the suction hopper 1 is fixedly connected with a grain conveying slide plate 2, and the grain conveying slide plate 2 is located at the suction Above the lower wall of the wind hopper 1, the lower wall of the suction hopper 1 has a suction through hole 14, the suction through hole 14 is located below the grain conveying slide 2, the suction through hole 14 is connected with a suction connection pipe 12, and the suction connection The other end of pipe 12 is connected with suction motor 6; The drive shaft extends into the volute 8 through the through hole on the right side wall of the volute 8, and the centrifugal fan 7 is fixedly installed on the drive shaft of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com